© Railway Wonders of the World 2012-

| Advertisements |

| Articles by Cecil J Allen |

| Binding |

| Cookie Policy |

| Covers |

| Donate |

| FAQs |

| Illustrations |

| More on Railway Wonders |

| Other Series |

| Privacy & Terms of Use |

| List of Illustrations |

| Locomotive Illustrations |

| Carriage Illustrations |

| Wagon Illustrations |

| Part 1 |

| Part 2 |

| Part 3 |

| Part 4 |

| Part 5 |

| Part 6 |

| Part 7 |

| Part 8 |

| Part 9 |

| Part 10 |

| Part 11 |

| Part 12 |

| Part 13 |

| Part 14 |

| Part 15 |

| Part 16 |

| Part 17 |

| Part 18 |

| Part 19 |

| Part 20 |

| Part 21 |

| Part 22 |

| Part 23 |

| Part 24 |

| Editorial - Part 1 |

| Editorial - Part 2 |

| Editorial - Part 3 |

| Editorial - Part 4 |

| Editorial - Part 5 |

| Editorial - Part 6 |

| Editorial - Part 7 |

| Editorial - Part 8 |

| Editorial - Part 9 |

| Editorial - Part 10 |

| Editorial - Part 11 |

| Editorial - Part 12 |

| Editorial - Part 13 |

| Editorial - Part 14 |

| Editorial - Part 15 |

| Editorial - Part 16 |

| Editorial - Part 17 |

| Editorial - Part 18 |

| Editorial - Part 19 |

| Editorial - Part 20 |

| Editorial - Part 21 |

| Editorial - Part 22 |

| Editorial - Part 23 |

| Editorial - Part 24 |

| Part 25 |

| Part 26 |

| Part 27 |

| Part 28 |

| Part 29 |

| Part 30 |

| Part 31 |

| Part 32 |

| Part 33 |

| Part 34 |

| Part 35 |

| Part 36 |

| Part 37 |

| Part 38 |

| Part 39 |

| Part 40 |

| Part 41 |

| Part 42 |

| Part 43 |

| Part 44 |

| Part 45 |

| Part 46 |

| Part 47 |

| Part 48 |

| Part 49 |

| Part 50 |

Locomotive Giants - 2

Some English Developments in Monster Engines

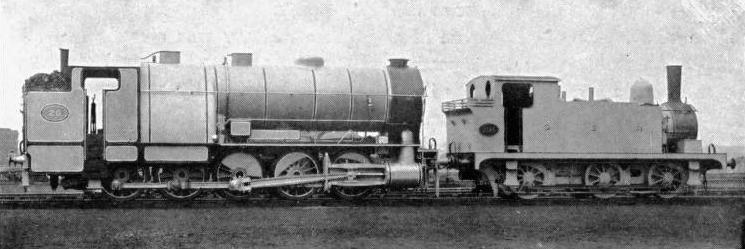

THE GREAT EASTERN “DECAPOD” IN COMPARISON WITH AN ORDINARY TANK ENGINE

IN discussing the big locomotive, as it is exemplified in various parts of the world, especially in North America, there is a tendency to overlook what has been, and still is being, accomplished in Great Britain. While the railways of these islands offer nothing to compare in size and power with the Mikado, Mastodon, and ten-

So far as the British Islands are concerned the physical characteristics of the country render the mammoth engine unnecessary. The engineers who laid our steel highways in the first place recognised the significance of the easy level line. Nature certainly favoured them in their work, inasmuch as there are no towering mountain chains to overcome, necessitating sudden heavy rises and falls. The summit level of 1,484 feet above the sea, attained on the Highland Railway between Dalwhinnie and Dalnaspidal stations, which represents the highest point at which the shriek of an express is heard in Great Britain, appears a mere molehill beside the 10,836 feet notched in the Marshall Pass of the Denver and Rio Grande, or the 5,329 feet attained upon the Canadian Pacific among the Rockies.

Nor are the gradients so severe. Whereas a train may be called upon to pant and throb for mile after mile up a bank rising 1 in 25 through the Rockies and Sierras, climbs of 1 in 50 represent the average maximum upon British railways, and in the majority of cases these are over only short distances. True, here and there are short stretches of steeper banks. For instance, on the South Eastern and Chatham Railway there is a heavy 594 yards run between Canterbury and Whitstable where the engine has to toil up a rise of 1 in 28. Again, on the North Eastern Railway there is a very wicked piece of road between Kirkby Stephen and Barnard Castle, where the train is called upon to overcome a difference in level of 725 feet in 8·75 miles, while between Ferryhill and Hartlepool is the Kelloe Bank, which offers an incline of 1 in 36 for about 1,300 yards. The London and North Western Railway also has one or two crippling rises at 1 in 33 for short distances upon its system, and on the Great Northern there is a heavy three miles between Drighlington and Batley West, where the ascent ranges from 1 in 40 to 1 in 50. In many instances, however, these adverse stretches exist only on branch lines, the main through roads, over which the fastest and heaviest traffic moves, having been built or improved to offer a ruling gradient which is by no means hard upon locomotive effort.

The ruling gradient, it may be pointed out, constitutes the key to the whole situation. As its name implies, its severity rules the hauling and speed capacity of a single engine. For instance, suppose a stretch of road 100 miles in length has a maximum rise of 1 in 200, and that a single engine is able to move a train weighing 500 tons over this section at 30 miles an hour, but on the succeeding stretch the maximum grade becomes 1 in 100. Now, the foregoing engine will be unable to continue handling the same load at the same speed. The train either will have to be divided, a more powerful engine used to negotiate the 1 in 100 banks, or additional locomotive power will have to be utilised, either in the capacity of a pusher or a pilot.

In these islands possibly the issue is not so serious as in other countries where the physical conditions vary from wide expanses of gently rolling plains to towering mountain ranges. But in order to minimise the difficulty the engineer strives to “bunch” his grades. The line, say, of 1,000 miles is split into sections or divisions, each of which indicates the extent of one engine’s run with the train. If the engineer can succeed in compressing all his heaviest banks into one division it means that the additional locomotive power only will be required upon that section. One type of engine thus will suffice for all the easiest sections, so that the train can be kept intact over the whole 1,000 miles. On the heavy grade division extra or more powerful locomotives can be used. It may so happen, however, that the maximum grade is short, but very steep. Then, instead of attaching larger or more locomotives, a pusher engine will help to lift the train load over the short hump.

“Bunching the grades” is one of the latest developments in railway practice, short of entire elimination, and it is exercising a beneficial influence upon economical working. This idea was adopted in these islands in the earliest days of the railway era, although the majority of our engineers, when faced with sudden heavy rises, made detours in the effort to preserve the easy line. But even then they were not always successful. The North British Railway, for instance, bristles with many very heavy banks, such as the Cowlairs Incline, with its rise of 1 in 45 for 2,200 yards, and up which the trains with their double headers were assisted by a cable. The Commonhead Incline, on the same railway, has an even sharper ascent -

In many instances, during recent years, where the alignment is propitious, and where it is possible to effect a pronounced saving in the initial cost of construction without exerting any adverse influence upon the economics of operation, the principle of “rushing the bank” has been adopted. But the “velocity grade” is not viewed with general favour by engineers. It certainly offers many advantages upon a road running through thinly populated country, but is inadvisable in congested railway districts, owing to the disorganisation of traffic which must ensue when a train fails to attain sufficient momentum to rush the bank, and becomes stalled thereon until rescued by an additional locomotive.

The “Decapod”

While the evolution of the big locomotive in Great Britain has been somewhat rapid during the past few years, it has been comparatively free from any revolutionary development, such as the Mallet, produced in other parts of the world. The nearest approach to a sensation was that produced in 1903 upon the appearance of the “Decapod”, designed by Mr. Holden for the Great Eastern Railway. This engine was certainly a giant of its type, and although avowedly an experiment, it created a considerable stir.

The Great Eastern Railway probably handles a heavier suburban traffic than any other trunk system in the world. By remarkably skilful scheduling and organisation, the trains engaged in this service are handled with striking celerity, notwithstanding the limitations imposed by a bottleneck outside the metropolitan terminus. The heavily congested nature of the territory served demands smart manipulation of the trains at the intermediate stations, combined with a rapidly accelerating capacity on the part of the engines. At the time the “Decapod” came upon the scene the traffic was handled by six-

THE “DECAPOD”: IT HAD FIVE PAIRS OF DRIVING WHEELS AND WEIGHED 70 TONS

Mr. Holden sought to improve upon this performance. He set out to design an engine capable of hauling a 50 per cent, heavier load, and able to accelerate to a speed of 30 miles an hour in 30 seconds. If this were achieved, then, he argued, it would be possible to increase the train service as well as decreasing the train-

The engine was a distinct novelty to British practice, and possessed many interesting features. The five pairs of coupled driving wheels 54 inches in diameter, were driven by three high-

The trailing drivers were given a side play of ½ inch, the coupling rods being fitted with ball and socket joints. As the cranks of the three cylinders were set at 120 degrees in relation to each other, perfect balancing of the reciprocating parts was secured. In running order the locomotive scaled 70 tons. In order to minimise the drivers slipping, especially when starting upon greasy rails, special attention was devoted to the sanding apparatus, a method of projecting the sand upon the rails by means of compressed air being incorporated.

The locomotive was subjected to searching tests under all conditions of traffic and weather, and fulfilled the anticipation of its designer. Unfortunately, however, it was found to be too heavy for some of the bridges on the system, and consequently after a brief career was withdrawn from service. It was taken back to the shops and converted into an 0-

The “Great Bear”

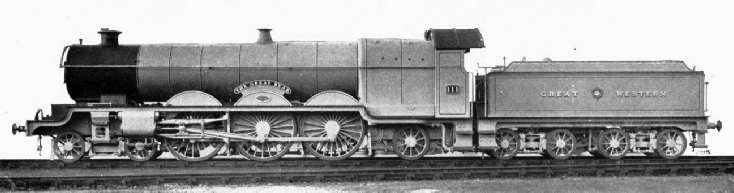

The Great Western Railway, with its characteristic progressive spirit, has been particularly enterprising in its locomotive development, especially during the regime of the present locomotive engineer-

“THE GREAT BEAR” READY FOR THE ROAD

Following the American practice, the Atlantic type was introduced for express w working, and in due course this was evolved into the Pacific class, which the Great Western Railway was the first to introduce into this country, and which even to-

Its boiler measures 23 feet in length by 5 feet 6 inches at the front, and 6 feet at the back, external diameter, with a total heating surface including superheater tubes and fire-

The introduction of the superheater represents one of the most important improvements which has been effected in the steam locomotive during the past few years. As is well known, water evaporates near sea level at 212 degrees Fahr., but the steam is not a pure gas. Minute molecules of water are associated with it, which depreciate the power-

Some years ago the fact was realised that if the water present in the steam were eliminated, then the steam could be made to perform more useful work, as it would be converted into a superior gas, possessed of greater expansion properties. Under these conditions a smaller quantity of steam would be sufficient to accomplish the desired end in a cylinder of given dimensions than if saturated steam were used. Such a development would influence other factors. The boiler pressure could be reduced, and the cylinder increased in diameter to obtain the same or greater tractive effort, while there would be a saving in coal and water consumption, and, incidentally, in the upkeep of the boiler and fire-

Accordingly numerous experiments were carried out to devise an efficient means for drying or “superheating” the steam. Remarkable ingenuity has been displayed in the evolution of the most suitable apparatus to accomplish this end. The steam, as it issues from the boiler, is passed through an additional nest of tubes upon which the gases of combustion from the fire play before escaping into the air. The result is that the temperature of the steam is raised to as much as 600 degrees or more, and every trace of saturation is eliminated.

The practice came into vogue first upon the Continent, where to-

The superheater tubes of “The Great Bear” have a heating surface of 545 square feet. The area of the fire grate is 41·79 square feet. The coupled driving wheels are 801 inches in diameter; the leading bogie wheels 38 inches and the trailing wheels 44 inches in diameter respectively. The tractive effort is 29,430 pounds; that is to say, if a chain were passed from the draw-

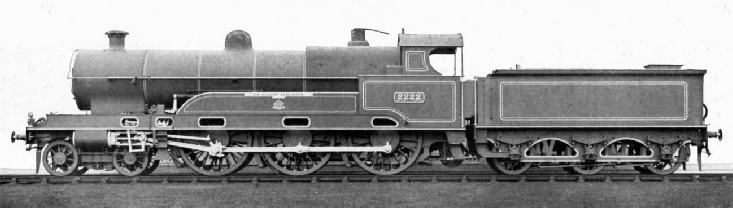

The “Sir Gilbert Claughton”

A heavy locomotive, the ten-

THE LONDON AND NORTH WESTERN RAILWAY’S LARGEST LOCOMOTIVE, THE “SIR GILBERT CLAUGHTON”

This engine possesses many interesting features. Although there are four cylinders of 18 inches diameter, by 26 inches stroke, simple, and not compound, working, in accordance with the general trend in recent locomotive practice, is adopted. The cylinders are placed in line with the piston valves above, and all drive on the leading coupled axle. The Walschaert valve gear has been embraced for the first time upon the London and North Western system, while the fire-

The boiler is 14 feet 6 inches in length, by 5 feet 2 inches in diameter, the centre line being 8 feet 9 inches above the rail level. The fire-

The wheels of the bogie truck have a diameter of 39 inches, while the drivers are of 81 inches diameter. The tender carries 6 tons of coal and 3,000 gallons of water. The over-

The “Sir Sam Fay”

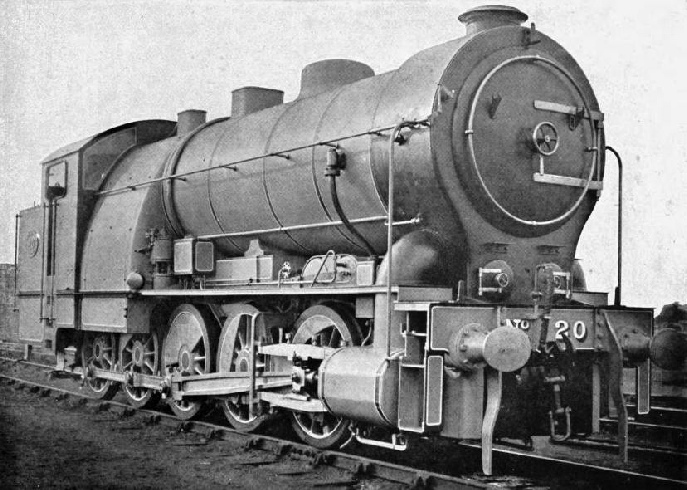

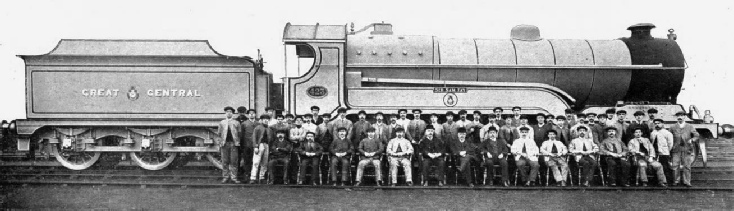

At the present moment the heaviest locomotive working upon British railways is the new express class which has been designed by Mr. J. G. Robinson for the Great Central Railway, the first of the six of which, the “Sir Sam Fay”, was placed on show at the Ghent International Exhibition of 1913. This likewise is a ten-

BRITAIN’S HEAVIEST LOCOMOTIVE: THE GREAT CENTRAL RAILWAY'S “SIR SAM FAY”

The coupled driving wheels are of 81 inches and the bogie wheels of 42 inches diameter respectively. In working order the weight of the engine and tender is 122 tons. This large and powerful locomotive has been designed especially for handling the heaviest express trains over the severe gradients of the Great Central Railway in the Midlands. Its neat symmetrical appearance contrasts vividly with the gaunt skeleton-

Thus it will be seen that, although British railways have not gone to the limits of the mammoth locomotive adopted in Continental Europe and the New British World, a steady forward movement is being maintained upon gradual lines. Undoubtedly during the next few years this tendency will become more marked, seeing that British rolling stock is growing heavier, while longer trains are being brought into vogue. This development applies not only to long-

You can read more on “British Express Locomotives”, “The Development of the Decapod” and “From the Atlantic to the Pacific” on this website.