© Railway Wonders of the World 2012-

Testing a Locomotive

How the Efficiency of a Modern Railway Engine is Proved

THE INDICATING SHELTER attached to the front of a “Pacific” locomotive undergoing tests. Members of the engineering staff ride in this compartment for the purpose of taking indicator diagrams of the expansion of the steam in the cylinders and collecting various smoke-

A DESIGNER’S work on a locomotive does not end when the product of his brain begins work on the track. It is not enough that the engine hauls its load within the scheduled time.

Once on the track it must be tested to ascertain the horse-

But the horse-

Another important line of investigation concerns the boiler; the designer will want to know that the combustion of the fuel on the fire-

Round the front and two sides of the smoke-

The indicator itself consists of a small vertical cylinder with a rotating motion, worked by a connexion off the motion of the engine. Every time the driving wheels of the engine rotate, the indicator makes one complete forward turn and one backward turn, so that it is in rapid motion, forwards and backwards alternately, all the time the engine is running. An opening is made in the front cover of one of the cylinders, and from this a small tube is led to the indicator. In this steam-

As the piston moves away from the cylinder-

It is of this process of expansion that the indicator diagram gives an exact picture. At the selected moment the observer in the shelter opens a cock in the small steam tube; the pressure in the tube actuates a small pen, which rises and falls according to the actual pressure in that end of the cylinder; the pen makes a line on the rotating cylinder of the indicator, to which a sheet of paper has been fixed. It is shaped like a boot. The top horizontal part of the “upper” shows the pressure as steam is admitted up to the point of “cut-

From the indicator diagrams, which are taken at a large number of selected points during the test journey, it is possible not only to watch the process of expansion in the engine cylinders at all speeds, but also to make an approximate calculation of the total horse-

Calculating the Power

The remainder, which represents the value of the locomotive as an operating unit, is available for the haulage of its train, and this has now to be measured. The difference between the two figures will show how much of its power the engine has expended in moving itself.

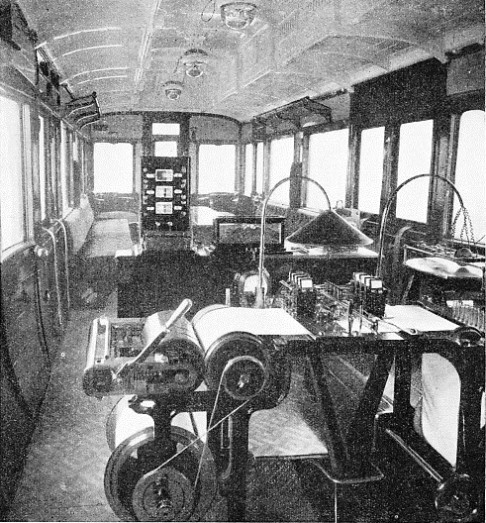

RECORDING INSTRUMENTS of various kinds are carried inside the dynamometer car. In the foreground of this picture is the machine for recording the drawbar pull of the locomotive, which is marked on the roll by one of the nine pens in the centre of the table. In the background is seen the apparatus for analysing the gases in the smoke-

This brings us to a special vehicle, known as a “dynamometer car”, which is used for measuring the pull exerted by the locomotive on its train. The dynamometer car is marshalled in the train next to the engine tender, and at its leading or business end the coupling hook of the car forms part of a drawbar of special design. This drawbar is attached to a powerful system of springs under the car, against which it pulls, and which reduce its forward and backward movements within narrow limits. By careful design and calibration the springs are so arranged that the movement of the drawbar is exactly proportionate to the pull that the engine exerts on it.

Inside the car, the visitor’s attention is first attracted by a table at one end, over which is passing a wide band of paper, winding from a large roll on one side of the table to another roll on the other side. The paper is being kept slowly in motion by clockwork or other suitable method. Poised above the table are a number of pens, each one of which has some special function to perform in marking the roll during the course of the test journey. The most important of these pens is the one which, by a system of levers, is directly connected with the drawbar described in the last paragraph. This pen is in constant contact with the roll and inscribes on it a complete picture of the engine’s pull on the train from the start of the journey to the finish.

The biggest effort of all occurs at the moment of starting. Cut-

The most important line along the dynamometer car diagram thus begins with a sharp peak, and then drops to a wavy horizontal line, rising when the train is running uphill and when greater horse-

Fuel Combustion Analysed

Inside the dynamometer car there is another important apparatus, which is directly connected by tubing with the interior of the engine smoke-

Among other details connected with a test journey of this description, it is important to keep a close check on the quantity of coal and water used. The coal is weighed as it is deposited in the tender prior to starting, and the residue is weighed again at the end of the journey; the difference, with the addition of what was used for “lighting up”, gives the total consumption on the route. The water in the tender tank and in the boiler is measured before the start and after the termination of the run. The supplies that were picked up from track-

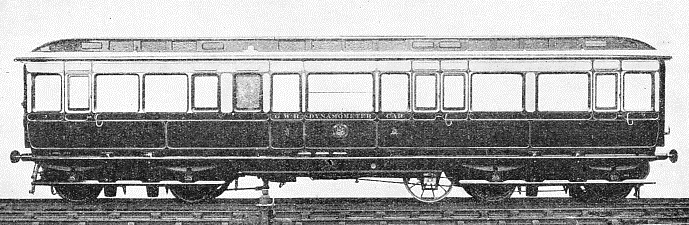

A DYNAMOMETER CAR, attached between the locomotive and the train, is used for making tests under working conditions. This coach is 48 ft 5 in long and weighs 27 tons 3 cwt. In the car a moving roll of paper, on which the principal records are made, is operated by clockwork and the extra wheel shown. This can be raised or lowered from the underside of the carriage to the rail as required, and is used to record on the roll the speed at which the train is travelling. The wheel is fitted with a hardened steel tyre, ground to such a diameter that it makes exactly 440 revolutions for each mile run.

Busy though the observers on the engine and in the dynamometer car have been during the course of the test journey, they are busier still when the run is ended, for all the diagrams have now to be worked out, and the mass of figures that has been accumulated requires detailed and critical analysis. The results are of the greatest value, and fully justify the considerable expense of maintaining the equipment and providing the staff of nine or ten skilled engineers that is needed to conduct such tests as these. As a result of studying the indicator diagrams, for example, the authorities may decide to make alterations in the valve-

Testing of this description is also used to precede time-

There is another way of testing a locomotive, which reproduces all the conditions of running, in the matter of load and speed, but without requiring that the engine shall be taken for a test journey over a stretch of line with the dynamometer car.

This method is independent of weather variations, especially of the effect of side-

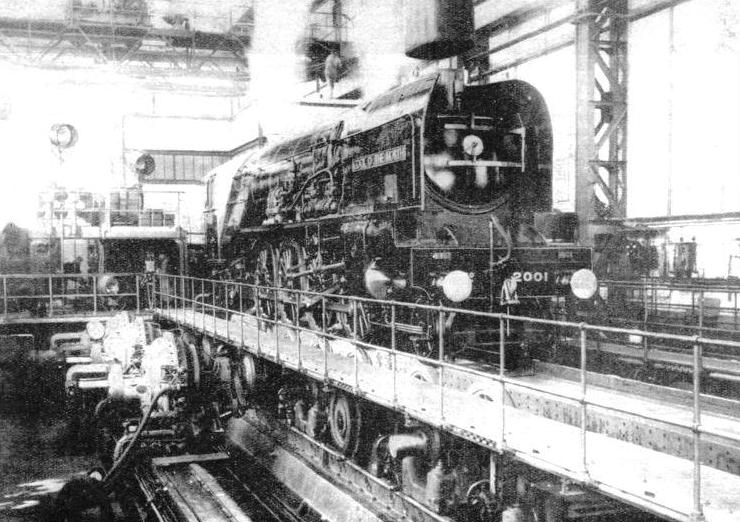

One of the most up-

The drawbar or coupling of the engine is then attached to a hydraulic dynamometer, which is anchored to a vertical girder set in concrete. The engine, held thus securely in position, is put in steam, started, and worked up to the equivalent of a high speed, travelling, theoretically, some hundreds of miles.

Standing on its rollers, roaring as though travelling speedily on a track, with the driving-

ON TEST. The “Cock o’ the North”, the great LNER 2-

At its best, the steam locomotive is, thermally, one of the least efficient of steam engines. Out of every 100 units of heat developed by the consumption of the fuel on the fire-

When the steam has done its work in the cylinders, and is thrown out of the chimney, a good deal of power goes with it, as is evident from the noise that is made by the exhaust, especially when the engine is starting. Owing to the relative short-

Throwing the exhaust up the chimney provides the necessary draught for the fire, and the terminal pressure of the steam before exhausting must be sufficiently high, or there will not be sufficient draught to enable the boiler to steam correctly.

Undue lengthening of the boiler barrel, to utilize a larger proportion of the heat of the fire for steam-

Forced Draught Experiments

Attempts have been made to trap the escaping power and heat, by substituting turbine drive for reciprocating motion, by condensing the exhaust steam and by substituting some form of forced draught, but without any marked success, because of these constructional limitations in locomotive building.

For the wide range of duties that it has to perform, the steam locomotive, despite its low overall thermal efficiency, is still the most suitable type of machine for its work. Efforts are being made constantly to increase the efficiency figure; from 7½ to 10 per cent, for example, would alone add one-

There are other important tests that precede the building of a locomotive. Every steel plate or rolled section used in its construction was inspected and tested by representatives of the railway company at the rolling mill where the steel was produced. Steel forgings and castings were subjected to a similarly careful scrutiny, as well as the copper from which the internal firebox has been shaped, and the tubes connecting the firebox with the smoke-

All these various parts have been manufactured to rigid specifications which have been drawn up as the result of experience, most of them the work of the British Engineering Standards Association. A large corps of inspecting engineers is maintained by each railway company, and travels the country visiting, for inspection and testing purposes, the works of firms that supply railway materials. Each railway also maintains its own laboratories, staffed by expert chemists and metallurgists, who have much testing to do in connexion with locomotive work.

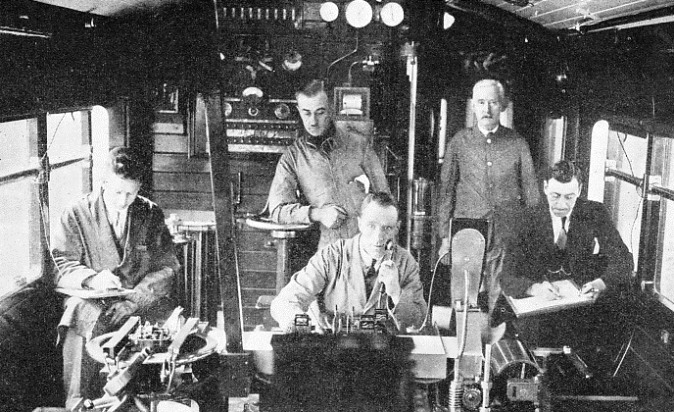

MEN OF A DYNAMOMETER CAR, attached to the “Flying Scotsman” express on the London and North Eastern Railway. The engineer at the central desk is in telephonic communication with a colleague on the locomotive.

Another aspect of locomotive testing, however, relates not so much to efficiency in design and performance, as to the matter of safety. For example, the axles of a modern express locomotive are usually made hollow. These are specially bored to allow the interior to be microscopically examined so that any flaws or defects may at once be apparent. The danger of a broken axle may thus be averted by periodical inspections during the running life of the locomotive.

Other tests are carried out from time to time, particularly with regard to boilers. These are inspected at specified intervals of time, so that any signs of corrosion may be detected.

A boiler is subjected to rigorous tests before being fitted to a locomotive. The boiler, after it leaves the shop where it is built, is tested under a hydraulic pressure at a figure which is well above its working pressure. In this test the boiler is filled with water. A powerful pump then forces in more water until the pressure gauge registers the required figure.

This, though severe, is not regarded as sufficient for complete safety, and the boiler is subjected to a further test, steam being raised until the working pressure of the boiler is attained. At this figure the safety valves are set to blow off, but the engineer's test proves that all joints in the boiler shell and between the tubes and the smoke-

A large number of tests are carried out, also, during the building of a locomotive, to ensure both efficiency and safety in working. An example of this is the elaborate testing of locomotive driving wheels before they are fitted to the engine frames. Driving wheels are operated by connecting rods which in their turn are worked by reciprocating motion.

Additional Tests

These reciprocating parts are very heavy, and “balance weights”, as they are known, are attached near to the rims of the wheels. These weights are placed opposite to the crank-

There is yet another aspect of locomotive testing which is of vital importance. This is the distribution of locomotive weight over each of its wheels. This is adjusted by running the locomotive into a special shed in which the track is divided up into a series of short weigh-

The locomotive undergoes a series of tests throughout its construction. Tests are also taken during the running life of the engine to ensure that it shall be safe and efficient.

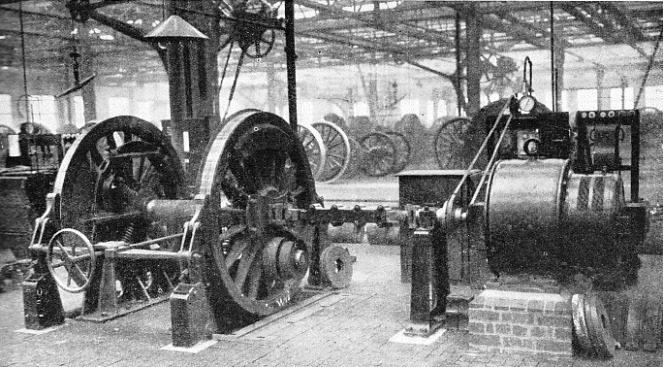

WHEEL BALANCING, an important part of a locomotive’s testing which is carried out during construction. This machine, at Swindon locomotive works, is used to ensure that all engine driving wheels shall be capable of spinning without undue vibration, at a speed equivalent to over sixty miles an hour on the track.

You can read more on “A Test Run on Cock o’ the North”, “Halls of the Giants” and

“How Engines are Tested” on this website.