© Railway Wonders of the World 2012-

Halls of the Giants

Modern Workshops Where Locomotives are Built

[Due to the length of this article, the following bookmarks are provided with links to the various workshops described]

North British Locomotive Co Ltd

THE growth of the locomotive, beginning in the humble iron-

In the early days of railways contracts for locomotives were generally placed with engineering firms specializing in steam-

One of Britain's most important railway centres for the construction of locomotives and rolling-

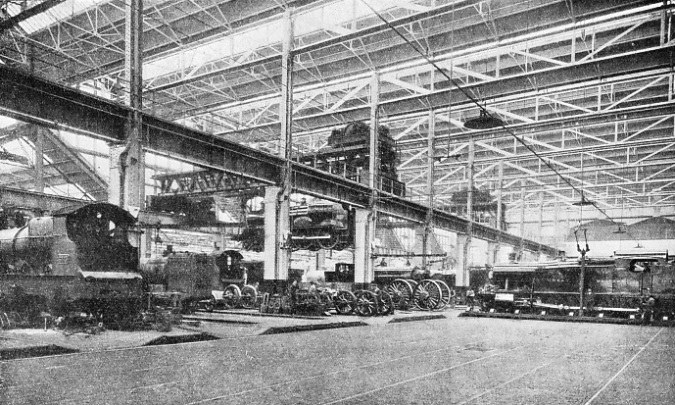

SWINDON’S ERECTING SHOP. The locomotives to the left of the picture are standing over the “pits” in process of construction. The express passenger engine suspended from the overhead travelling crane should be noted. On the right is a large Great Western tank locomotive on the electric traverser that runs on rails laid across the shop. The current is supplied to the traverser by two overhead cables, and the collector arms can be seen just over the tank engine’s firebox.

An express will appear “round the corner” of a vast machine shop and disappear majestically through the works yard. Tunnels under the main lines, however, obviate any danger to the workmen in the course of their duties. The locomotive works were finished and brought into operation on January 2, 1843. Swindon's population at that time was under 3,000; in 1935 it had risen to over 65,000, of whom some 12,000 are employed at the Great Western Works. The Works at Swindon cover about 310 acres, of which 65 acres are roofed. The locomotive shops are on the north side of the main line to Bristol; the great “A” Shop where the engines are erected is one of the largest workshops, under one roof, in Britain.

One of the first items of interest to be seen in the great Erecting Shop at Swindon is the replica of the Great Western's first locomotive the “North Star” -

At Swindon

In this shop all types of the company's locomotives are built from the components supplied by the machine, boiler, and other workshops. Repairs also are carried out here, and the equipment for this work is so efficient that about 400 large locomotives can be reconditioned and overhauled yearly. An impressive feature of the Erecting Shop is the overhead crane equipment. When required one of these electric giants will be moved over a great locomotive. Chains are attached fore and aft, and the 100-

These overhead cranes are used also to carry heavy components such as wheels, cylinder castings, and boilers from the foundry or shop where they are made to the building site of the engine for which they are intended. Lighter parts are carried from place to place by post-

The shops in which the locomotive frames are machined are full of interest. Here the huge steel plates are shaped with oxygen flame-

The Boiler Shop at Swindon contains some of the most noteworthy machines to be seen in the service of the engine builder. There are flame-

Still more spectacular in their action are the large machine tools that fashion the big cylinder castings and other components of a modern locomotive. In planing machines the castings are moved backwards and forwards on iron tables, while steel tools cut into the cast iron and leave a smooth, accurately machined surface.

Apart from the immense shops at Swindon, where the heaviest of work is done, there are others in which numbers of light machines turn out the vast quantities of smaller components that are incorporated in a modern locomotive. There are automatic machines, fed with steel, copper, or brass rods, that turn their supply of material into nuts, bolts, firebox stays, screws, and a host of other items without which the engines could not be constructed. No reference to a modern locomotive works could be complete without mention of the Drawing Office, where the designers' ideas are interpreted to the craftsmen by means of blue prints, thousands of which are prepared in the course of a year, dealing with every part of the locomotives built in the shops.

The enormous workshops of the London, Midland and Scottish Railway at Crewe were entirely reorganized after the railway amalgamation of 1923 and rank among the largest and most up-

The South Erecting Shop at Crewe is an enormous building 910 ft long. The width of the building is 194 ft, with a height to the eaves of 35 ft. This shop is laid out for the operation of a belt or “processing” system, somewhat resembling the conveyer method of building motor cars by mass-

At every stage point in the shop a large dummy clock is placed, with the words “Next Move” above it in bold letters. Below these words, the day of the week is displayed on removable boards and the time of the move is indicated by moving the clock hands. The engines are hauled from stage to stage by steel cables and electric cranes. The large Erecting Shop at Crewe is capable of turning out a hundred new locomotives a year, and of doing heavy repairs to some thirty or thirty-

In addition to the works at Crewe, the London, Midland and Scottish Railway has the shops at Derby, where the former Midland Company built its locomotives, carriages, and wagons.

The Derby Machine and Fitting Shop is 450 ft long, 250 ft wide, and is very well staffed. All machining operations on locomotive components are carried out in this shop with the exception of work on wheels and axles. The Machine Shop is divided into six bays, housing no fewer than 540 machines, the driving belts of which total ten miles in length.

All screws, pins, and rivets -

The preparation of cutting tools for machines in the various shops is done in a special Tool Room. The hardening of the tools is carried out by means of gas-

Other shops are devoted to the production of cylinders and of frames. Frame plates are cut at Derby Works with the oxy-

The Erecting Shop is 450 ft long and 150 ft wide, and employs a large number of men. There are three bays with accommodation for thirty-

The enormous number of parts that go to make up a modern locomotive is not generally realized. A 2-

A British railway speed record -

The Progressive System

Doncaster Works, as well as those at Crewe and Derby, are organized on the “belt” or progressive system, both for the repairing and for the building of locomotives. We have described the building of a locomotive in an earlier chapter. The repairing and overhauling of engines has, under modern conditions, been evolved into a fine art. This is a necessary development, since speed and efficiency in engine repairing are two of the most important factors in locomotive operation. A locomotive not in service is an encumbrance that is not earning its keep.

A system has been perfected at Doncaster so that engines pass through the shops in a minimum of time. On entering the works yards, the locomotive’s ash-

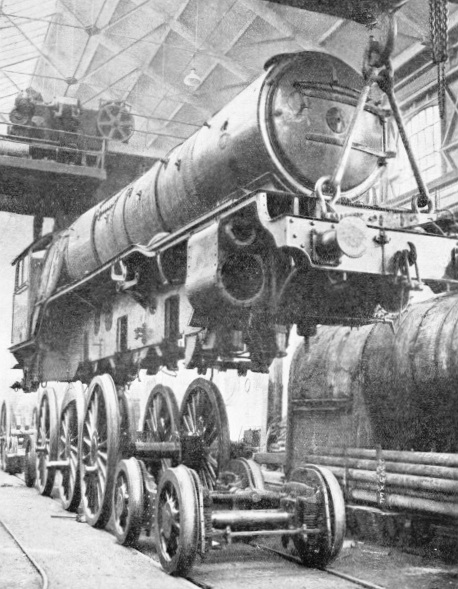

WHEELING A LOCOMOTIVE at the Doncaster works of the London and North Eastern Railway. This “Pacific” type engine, held at either end by an overhead electric crane, comprises the frames, cab, cylinders and boiler. After lowering on to the wheels the valve gear and motion work will be added to the locomotive.

The electric traverser then takes the engine in hand and transports it to one of the erecting shop roads. After hauling into this department, the wheels are removed for inspection and re-

A separate department, the Machine Bay, is devoted to the fitting of axle-

Another interesting machine is that used for boring locomotive connecting and coupling rods. Both ends of the rod forging are “trepanned” at the same time. This process entails the use of a hollow circular cutting tool that bores a hole but leaves a solid cylindrical block of metal that drops out of the cutter when the boring is completed. Since this block is not cut away, as it would be on using a very large drill, a saving of both time and power is effected.

After further boring, the rod holes are finished dead to size on a double-

Adjoining the Machine Bay are the Erecting Shops for building new locomotives and for repairing those withdrawn from service for the purpose. The three main erecting bays are equipped with four 35-

The Wheel Shop is completely equipped with every modern device for the machining of locomotive wheels. The plant includes wheel lathes, axle lathes, tyre borers and heaters, crank-

The Southern Railway’s works, which include the Carriage and Wagon Shops in addition to those for locomotives, are situated at Eastleigh, Hampshire, on the London to Southampton line. The Eastleigh Works formerly belonged to the London and South Western Railway, and became the principal centre for locomotive and carriage construction on the formation of the Southern Railway in 1923. The locomotive works have been entirely reorganized, and with the closing of Brighton works, the demand on the Eastleigh shops has been increased. Over 1,000 engines have to be maintained, in addition to the construction of new engines.

The works cover an area of eighty-

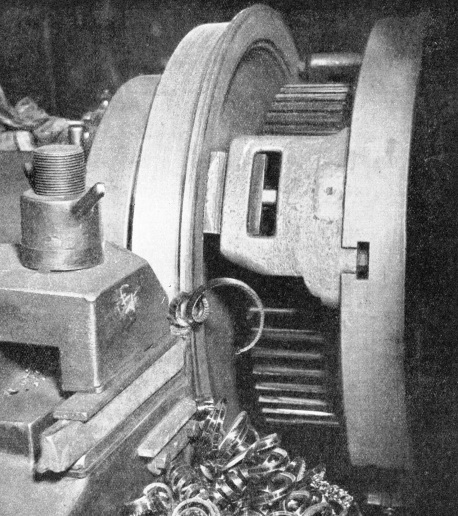

TYRE TURNING on a powerful wheel-

The used sand from the moulds is not thrown away, but, after falling through a grating on to an elevator, it is passed to a magnetic separator that removes any small particles of iron that may be left in it. After passing through a screen, a cooling hopper, and also a grinding mill the sand is aerated, and returned to hoppers over the moulding machines for use again.

The three cupolas serving the foundry have an output amounting to 90 tons of molten metal a week. Castings in non-

A Pattern Shop supplies all the patterns for use in both the Iron and Brass Foundries. Eastleigh also manufactures its own fire bricks for locomotive firebox arches and for furnace linings. The kiln attached to the brick shop holds 10,000 bricks, and two kiln loads are produced each month.

The Forge is equipped with one 3-

Among the interesting machines at Eastleigh works are those used to reclaim the oil from engine drivers’ and cleaners’ cloths. The oily rags are placed in a large perforated drum, which revolves at high speed inside a casing. As the drum whirls round the oil is flung out through the perforations, and is collected for further use. The dry cloths are then ready for re-

The supply of electric power for the works is obtained from Southampton Corporation mains. The alternating current, at 6,600 volts, three-

The Boiler Shop consists of two bays, each served by a pair of overhead travelling cranes-

There are a number of large and small radial drills and a 75-

The fire tubes of a modern locomotive require periodical renewal, and a special shop is set aside at Eastleigh for the reconditioning of tubes on the Southern Railway's engines. After removal from the boiler, the tubes are de-

A Millwrights’ and Electricians’ Shop is set aside for the maintenance of the works mechanical and electrical plant, and part of the shop is used for electric and oxy-

A Millwrights’ and Electricians’ Shop is set aside for the maintenance of the works mechanical and electrical plant, and part of the shop is used for electric and oxy-

MASS PRODUCTION. A corner of the turret lathe machine shop of the Southern Railway’s works at Eastleigh. These machines make large quantities of bolts, screws, pins, and a variety of small components which are used in the building modern locomotives. The lathes are driven by belts from overhead line-

The Smiths’ Shop is equipped with six steam hammers ranging in size from one quarter to half a ton. Locomotive and tender springs are made here, and the shop also contains grinding machines with dust-

The Machine Shop is divided into five sections. One contains planers, slotters, and shapers; a second is equipped with heavy duty lathes. Turret lathes for the mass production of special screws, bolts, and pins are in a third. The fourth section contains a complete range of both large and small drilling machines. In the fifth section are housed the heavy machine tools such as frame slotters and drillers, large planers, and horizontal boring machines.

Other equipment in the Machine Shop includes a battery of special turret lathes for the production of copper stays from bar material. Each machine turns out fifty completed stays an hour. Oxy-

The Tool-

Some of the heaviest and most important machinery at Eastleigh is to be found in the Wheel Shop, where great lathes are installed capable of turning locomotive wheels up to a 7 ft 6 in diameter. Here also are tyre-

Eastleigh’s Erecting Shop, for repair work, is divided into two bays, one for large and one for small engines. The large locomotive bay is served by two 50-

Reconditioning is carried out systematically, locomotives entering at one end of the shop for stripping, after which the components are passed through a bath of boiling caustic soda large enough to take a complete engine bogie. The stripped frames are then moved up the shop for squaring, straightening, and other reconditioning processes. Reassembly of the locomotive is then proceeded with, and new components are incorporated where necessary. The completed engine is finally placed on a valve-

The special equipment in the Erecting Shop includes appliances for the fitting of axle-

New engines are built in a third bay. A fourth is used for repairing tenders. Other departments include a metallurgical laboratory, paint shop, stores, and a fully equipped ambulance room. Transport between the various shops is effected by petrol trucks fitted with lifting tables. The number of workmen employed at Eastleigh is about 1,400.

Established in 1830, the famous Vulcan Foundry at Newton-

A Famous Foundry

Sir Daniel Gooch, Brunel's famous assistant and later the Locomotive Superintendent of the Great Western Railway, served his apprenticeship at the Vulcan Foundry, which he joined on January 28, 1834. Subsequent development of the firm was in the hands of Edward Tayleur, Dupré, Samuel Sanderson, W. F. Gooch (younger brother of Sir Daniel), and Sir William Collingwood, KBE, who died in 1928.

The Vulcan Foundry now stands in eighty-

The equipment is modern in every detail, and all types of locomotive are constructed throughout for any gauge, British or foreign, at the Vulcan Foundry. The Drawing Office -

Woodworking may not, at first sight, appear to enter very largely into engine building, but the Vulcan Pattern Shop is 180 ft long and 39 ft wide, and employs fifty men. Here are made the wooden patterns used in preparing moulds tor castings in the foundries. A joiner’s shop, the same size as the pattern shop, is used for the making of all timber fittings for locomotives and the huge packing cases for shipment.

There are two foundries, one for iron castings, the other for non-

The Smithy at the Vulcan Works is 419 ft long and 44 ft wide; it is equipped with eleven steam hammers, besides forging machines, power saws, and blacksmiths' forges. Heavy forging is done in a shop 210 ft long and 45 ft wide, equipped with steam hammers of 1, 1½, 3, and 5 tons. An important process in this shop is the annealing, in a special gas furnace, of all forgings.

One of the largest shops at the Vulcan Works is the Boiler Yard, a great covered hall with a floor space of 8,350 sq yds, arranged in three bays, one of which is 63 ft high and equipped with double tier overhead cranes. There are more than thirty cranes of all types in the Boiler Yard, varying in size from 2-

All plate-

Boilers, after staying and riveting, are brought from the Boiler Yard to a Mounting Shop (195 ft by 56 ft), for the fitting of internal steam pipes, regulators, domes, safety valves, fire tubes, and other parts to complete the boilers ready for their steam tests.

In addition to the great machine halls where the heavy work is done, there are many shops where special processes are carried out. There are grinding shops in which locomotive parts are finished dead to size by high speed abrasive wheels. A case-

A Giant Wheel Press

Automatic machine and light turning shops deal with such items as copper and steel firebox stays and the numerous fittings that are required for a modern locomotive.

Special shops are allocated to wheels, axles, and axle-

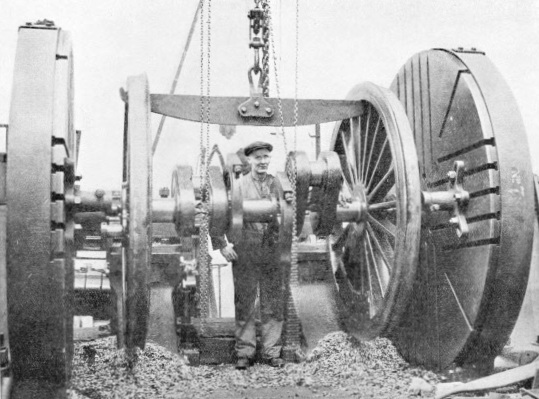

THE DOUBLE-

The Erecting Shop at Newton-

Adjoining the Erecting Shop is the Paint Shop, 187 ft long, which is provided with all the necessary equipment for modern methods of spray painting. The paint store and mixing machines are in this shop, which is steam-

The Power House at the Vulcan Foundry generates electricity for the whole of the works, and also provides compressed air for the pneumatic tools and hydraulic power for the presses in the wheel and boiler shops.

From Gorton Foundry, Manchester, locomotives are sent out to all parts of the world, and these include the famous “Beyer-

The Iron and Steel Foundries at Gorton occupy one large building, 400 ft long and 120 ft wide. The Steel Foundry is equipped with two 10-

The Forging Shop is provided with five steam hammers including one of 7½ tons. For heating the forgings before they are hammered into shape, the shop is equipped with gas-

The Smithy at Gorton comprises four bays, each 120 ft long and 40 ft wide. Here are steam and electro-

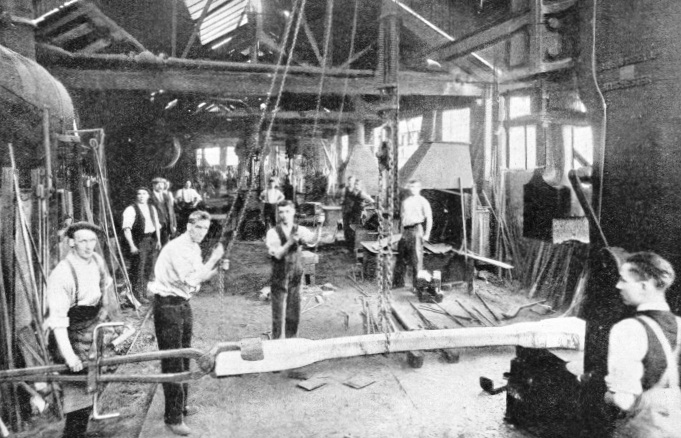

UNDER THE HAMMER. Forging a locomotive connecting rod in the Smithy at W G Bagnall’s works. The man at the right controls the blows of the power hammer, while the men with the chains lift or lower the heated billet of steel as necessary. The man at the extreme left manipulates the large tongs as the hammering proceeds.

The Pattern and Joiners' Departments are housed in a large building, adjoining which are other buildings used for storing the many thousands of patterns required by the foundry for different types of engine.

The Boiler Shop, one of the largest in Europe, is 600 ft long and 175 ft wide divided into three longitudinal bays and one riveting bay. The main bay of this shop has two crane gantries or runways, placed one above the other, The upper gantry accommodates travelling cranes of 50 tons capacity, and the lower carries 10-

The three boiler shop gantries lead into the Riveting Bay, which is high enough to allow the lifting of the longest boiler shells to a vertical position between the arms of a large riveting machine.

Adjacent to this bay and alongside the railway are large sheds for the unloading and storing of plates. Locomotive tenders also are built in the Boiler Shop, and a special section of the department is set aside for the hydraulic and steam testing of boilers before they are passed to the engine-

One of the largest machine shops at Gorton is used for the preparation of locomotive frames. This shop is 305 ft long and 75 ft wide, and has a single overhead gantry equipped with 6-

There are numerous machine shops, including those accommodating the automatic plant for the making of boiler stays and other components. A special department is devoted to the machining of locomotive cylinders. This shop is 160 ft long and 42 ft wide, and is equipped with a gantry and a 10-

Another important department at Gorton Works is the Wheel and Axle Shop, which occupies a building 250 ft long and 42 ft wide. The shop is equipped with heavy lathes for turning axles and wheels of all sizes. Other modern machinery in the department includes a 450-

The Erecting Shop, where the finished locomotive parts are sent for assembly, is provided with a central track having a pit throughout its length. Locomotives are built up, on their frames, on either side of the central track, which accommodates the wheels. On completion, the frames, with cylinders, boilers, and other components, are lifted on to the wheels and the engine is run out of the shop to the steaming shed for testing.

The Gorton Paint Shop is a lofty building 220 ft long and 55 ft wide, with three inspection pits running its entire length. The shop has a central track with multiple-

Other special departments include the Coppersmiths’ Shop, where both copper and steel pipes are prepared, in addition to the thin sheeting used for covering locomotive boilers. Another shop, 220 ft long, is set aside for storing jigs, chucks, and gauges of every description for use in the various machine shops. This department also contains a number of machines for testing the strength and hardness of the materials used in locomotive building. There is also a well-

An Internal Transport System

Gorton Works are supplied with electric current by Manchester Corporation at 6,500 volts, a proportion of which is transformed to A.C. at 220 volts and the remainder to D.C. The internal transport system at Gorton is highly efficient, and the works are laid out with concrete roads, on which run petrol-

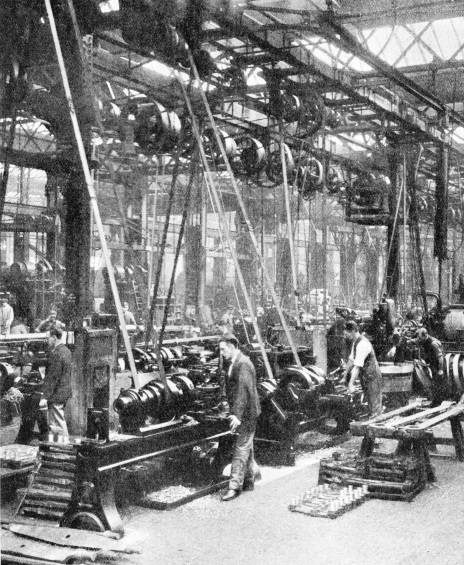

Neilson, Reid & Co, Dubs & Co, and Sharp, Stewart & Co, three famous firms that have played so important a part in locomotive history, now comprise the North British Locomotive Co Ltd, with headquarters in Glasgow. The Hyde Park and Atlas Works, formerly Messrs. Neilson Reid and Sharp Stewart respectively, cover an area of nearly thirty-

Most of the buildings of the three works have been reconstructed since 1907, and are of steel with glazed roofs giving ample light and liberal headroom. The workshops are so organized that, if necessary, the special process shops of one department can be put at the disposal of another. Employment would be given to over 5,000 men if these shops were worked to their full capacity of 350 locomotives a year. The Forge, which is situated at Queen’s Park, covers an area of 20,400 sq ft,and is served by three overhead cranes of 3, 7, and 10 tons capacity. The equipment includes ten steam hammers varying in size from 30 cwt to 2½ tons.

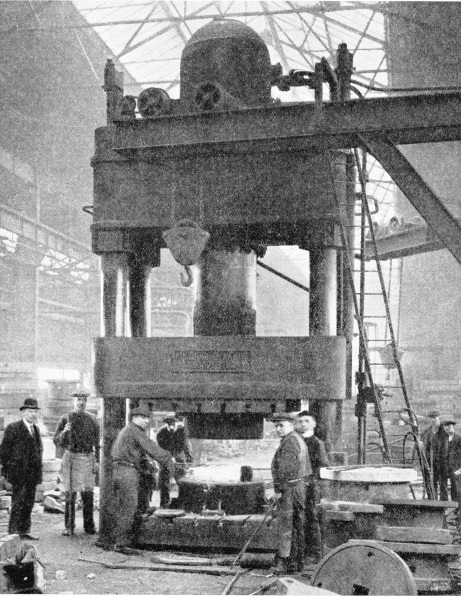

THE HYDRAULIC PRESS in the forge at the Queen’s Park Works, Glasgow, is capable of exerting a force of 1,500 tons. A white-

A special shop is devoted to the flanging of boiler plates at the Atlas Works, and covers 37,800 sq ft. There are two 10-

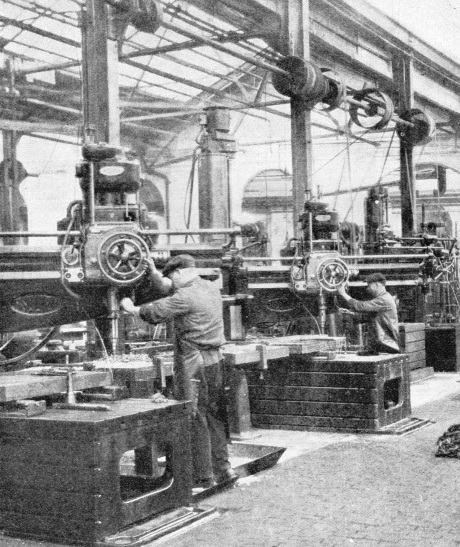

The frame and axle-

STEAM HAMMERS at Queen’s Park Works, Glasgow. There are ten of these hammers, varying in weight from 30 to 50 cwt. Despite their size, their action can be regulated with precision. The force behind the blows and the rate at which they are delivered can be adjusted as required.

Equipment in the wheel shops includes machines such as lathes capable of turning wheels up to 8 ft in diameter, and hydraulic presses of 200 tons capacity for pressing wheel-

The Cylinder Shops comprise a floor space totalling 57,200 sq ft, and are equipped with batteries of boring, facing, and planing machines.

In the Boiler Shops are seen some of the most interesting devices used in building modern locomotives. Here are great levelling and bending rolls capable of dealing with plates up to 12 ft wide and 1¼ in thick. There are also hydraulic riveting machines with arms 17 ft 6 in long, by means of which large boiler shells can be riveted complete. Special horizontal drilling machines mounted on columns 11 ft high are used to facilitate the drilling of boiler shells.

The Boiler Shop at Hyde Park has an area of 56,500 sq ft, and is served by six overhead cranes of various capacities from 10 to 40 tons. The Queen’s Park Boiler Shop (36,200 sq ft) is equipped with six cranes of 15 to 40 tons.

The company’s Machine, Turning, and Fitting Shops, where locomotive components are made and finished ready for the Erecting Shops have a total area of about 226,800 sq ft, and are well equipped with appropriate types of machine tools, and are served, where necessary, by overhead cranes. The Erecting Shops have an area of 35,600 sq ft at Hyde Park, and 63,000 at Queen’s Park, and the “pits” are arranged across the bays, and are served by overhead cranes of 90 tons capacity, running above cranes of 15/30 tons capacity.

In addition to the foregoing, there are many large shops for tank and cab construction, brass founding and finishing, tool-

The oxy-

The foregoing will give an idea of the immense size and efficient equipment of British locomotive works, but it is, of

course, impossible to include in one chapter a detailed description of every locomotive works in Great Britain. Similarly, it has not been possible to include other works of the principal British railways such as those at Horwich, St Rollox, Darlington, Stratford, and Ashford.

Since its inception the locomotive building industry has been a nation asset. Its reputation both for design and quality of material and workmanship is world-

RADIAL DRILLS at work simultaneously on four locomotive frames in the shops of the Hunslet Engineering Company, at Leeds. The drills are worked by independent electric motors, and the arms can be raised or swivelled by power on their supporting columns. The drill heads can be moved along the arms, so that holes can be drilled in any position in the plates, which are to be seen above, resting on the slotted tables.

You can read more on “How a Locomotive is Built”, “Locomotive Accessories” and “The Story of the Locomotive” on this website.

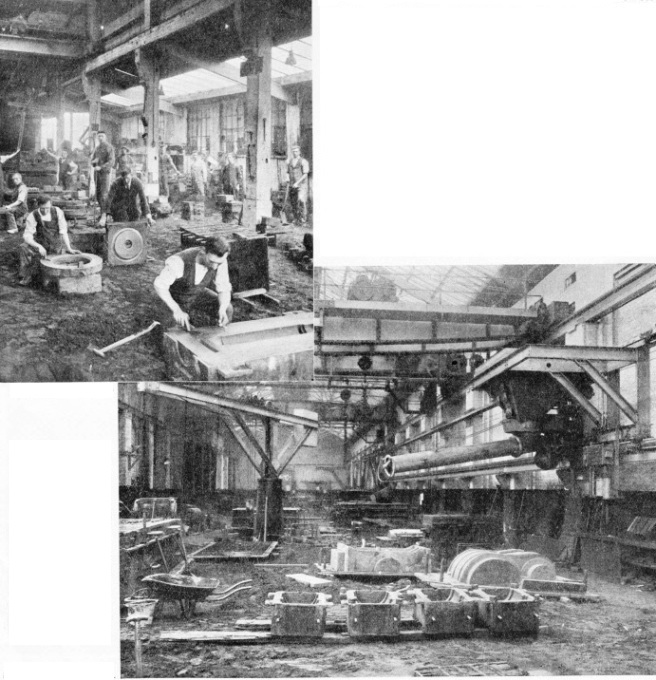

FOUNDRY WORK. Craftsmen at the Stafford Works of W G Bagnall Ltd are preparing the sand moulds into which molten metal will be poured in the making of castings (top picture). Below is part of the iron foundry shop at the works of the Vulcan Foundry Ltd. Note the overhead electric travelling cranes and the hydraulic crane in the centre of the shop. To the right is the travelling hopper for delivery to the moulding boxes, a row of which is seen in the foreground.