© Railway Wonders of the World 2024 | Contents | Site Map | Contact Us | Cookie Policy

Aerial Railways

A novel form of transport for conveying goods and passengers in mountainous districts

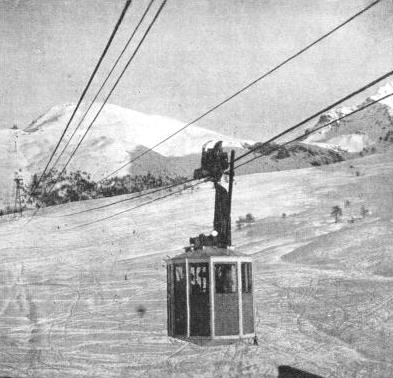

FOR WINTER SPORTS. A scene at Sestrières, in the province of Turin, 6,670 ft. above sea level An aerial railway carries ski-

HAULAGE by rope and pulley has been known since the earliest days, and although no graphic record is available, the evidence has been furnished by wooden pulleys found during excavations in Egypt. These pulleys date from about 2600 B.C. One of the oldest pictorial documents of rope haulage is an Assyrian bas-

There are several old prints in existence which show that the Chinese used a stretched rope as a means of transport. In one of these prints a man is seen standing in a basket suspended from a rope stretched across a narrow river and hauling himself by his hands along the rope.

The first practical aerial ropeway of which there is any definite evidence was devised by Adam Wybe, a Dutch engineer. During the construction of a fort at Danzig he used an aerial ropeway for the conveyance of earth from a hill outside the fortifications to the fort under construction. An endless rope, attached to which was a number of small buckets, ran between the two terminal points and was supported by intermediate standards. The buckets were filled at the hill and travelled on one side to the fort, where they were emptied and returned on the other side back to the hill. The rope ran round pulleys at both terminals and was driven by hand.

The same method, adapted to meet modern requirements, is still largely used and is known as the mono-

Although earlier patents had been taken out for aerial ropeways, the first practical and successful patent was granted to Charles Hodgson — an almost forgotten engineer — in 1868. In 1870 Theobald Obach, an Austrian engineer, invented the first practical coupling attachment for the suspension of the carrier from the rope, and thus solved one of the main problems of aerial rope transport.

From that date various firms in England and on the Continent began to specialize in this particular industry. Considerable technical difficulties had to be overcome, and because of these, more than forty years passed before aerial ropeway transport was made sufficiently safe to build a passenger-

At that time there were no by-

Since then an ever-

The use of aerial ropeways offers many advantages, the most important of which is that they can do work which for technical or economic reasons other forms of transport cannot do.

There is nothing spectacular about an aerial ropeway. It has no vast stations, no mighty trains that make the earth tremble. A few trestles, a few ropes — almost invisible at a distance — an insignificant building at each terminal, and at intervals a cage-

But although this means of transport may seem to be simple and toy-

Unique advantages

The aerial ropeway has the unique advantage over all other systems of transport that it is not limited by any obstacles or limitation of the ground. Even aeroplanes require flying grounds for taking on and landing, but the small space required for the terminal station can be hewn out of the rock even on the most barren mountain slope. A railway requires in the first instance the preparation of the ground, the boring of tunnels, the cutting of trenches, the construction of embankments, the building of bridges and viaducts.

The initial outlay for an aerial ropeway is very small in comparison with that required for the construction of a railway or a road, and does not increase in proportion to the length. In fact, assuming that the construction of an aerial ropeway would cost £3,700 for half a mile, the cost in equal conditions for a miles would be £7,500, and for 5 miles £15,500. This is accounted for by the fact that the most expensive part of the installation is the driving machinery, the cost of which does not alter within certain distinct limits and never increases in proportion to the length of the line. The maintenance costs and working expenses are small, and even on long lines often amount to only a few pence per ton.

Aerial ropeways may be divided into two main categories — the first where one endless travelling rope supports and moves the carriers; the second, where a fixed carrying rope is employed in conjunction with a moving hauling (or traction) rope, which is firmly attached to the carriers by means of special couplings. Each of these two categories comprises various systems, but the main principle of each always remains the same.

The first category, called the mono-

TO THE SKIES. Passengers can be carried in a few minutes to altitudes of between 8,000 and 9,000 ft. by this aerial railway, which links Sestrières to the heights of Monte Sises (8,530 ft.), and Monte Alpette (7,546ft.). This aerial railway proved so successful that it became necessary to construct a second line, to convey tourists to the Banchetta Crest.

The carriers are hung on the rope by means of saddles consisting of an iron frame which, by the interposition of blocks of wood or other suitable material, adheres to the rope sufficiently firmly to remain in position. A pivot arrangement assures the vertical position of the carriers over gradients.

At the terminals, where the carriers have to be loaded or unloaded, rails are mounted on supports at a height which is slightly below that of the ropeway. A special wheel-

In many instances the rails are laid on a down gradient, so that the carriers can travel by themselves over a short distance until they reach the place where they are loaded or emptied. They are then brought, full or empty, by rails to the other side of the pulley, and the same wheel device makes them engage the ropeway.

150 Tons an Hour

The installations for loading and unloading operations at the terminals are constructed for each individual ropeway according to the nature of the materials or goods, to the load capacity of the carriers, or to the hourly capacity of the ropeway.

The mono-

On the other hand, the capacity of a mono-

The longest line built on this system is believed to be that in Colombia. Its length is 46 miles, and the line is divided in 14 sections, as it would be impossible to have one uninterrupted endless rope, which would have to be more than double the length of the line.

In this example, as in all other examples where the line must be divided into sections on account of the length, each section represents an independent unit between two section stations. In each of these intermediate stations the conveyance of the carriers from one rope to the continuation rope is effected over rails in a manner similar to that described for the terminals earlier in this article.

The bi-

The bi-

The general principle of the bi-

This general principle of the bi-

This general principle of the bi-

NERVES OF STEEL. The men who repair the aerial railways become so indifferent to heights that they sometimes travel outside the cage. The railway shown in this picture runs from Merano to San Vigilio, up to an altitude of 4,856 ft. Merano is five hours' journey from Verona, and ten hours’ from Munich.

The second type is used for passenger ropeways. The carrying ropes are also running parallel, and usually one carrier is running on each side in opposite directions. The carriages leave both terminal stations simultaneously, pass each other midway, and arrive at the respective terminals at the same moment.

Various brake systems are used, the principal one being an automatically acting device attached to the carriage, which grips the carrying rope and brings the carriage to a standstill. As a further precaution a second, auxiliary, traction rope is sometimes used, which in the event of a breakdown acts automatically. This type of ropeway is also largely used for the transport of heavy single loads.

The carriages usually have a seating capacity for 24 passengers, but on some lines as many as 36 can conveniently be carried in each carriage. In order to ensure smooth running and a better distribution of weight, passenger carriages are suspended by eight or more wheels arranged in pairs mounted on swivelled frames.

The speed is usually 12-

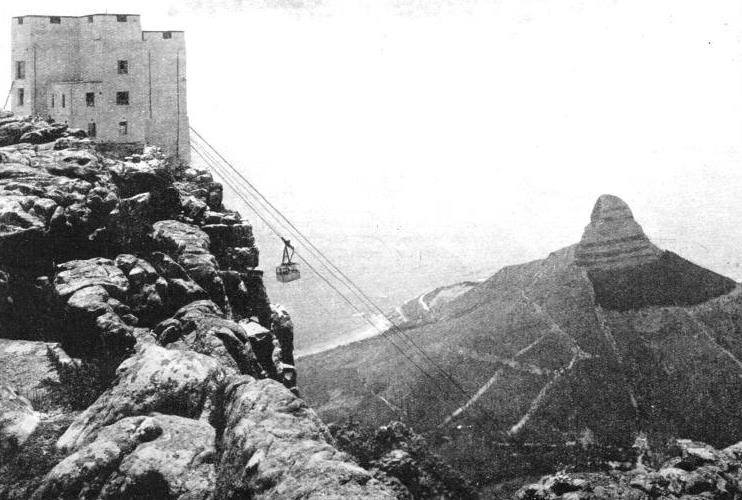

It takes only five minutes to reach by a single span the top of the Table Mountain at Cape Town and to negotiate the difference in altitude of 2,300 ft. The ropeway near Reichenhall in the Bavarian Alps reaches an altitude of 5,160 ft. with a rise of 3,610 ft. in nine minutes.

The aerial ropeway which ascends the Kohlerer Mountain in the Austrian Tyrol is one of the most remarkable aerial ways in the world.

The aerial railway begins at Eisack, and climbs up the side of the mountain for a distance of 5,250 ft. This distance is not covered in a single span. Twelve lattice steel towers were erected at varying intervals to support the track. The latter consists of steel ropes, each about 1¾ in. in diameter, and set some 19½ in. apart. There are two tracks, one for each of the two cars operating. The railway is run on the counterbalancing system. At the upper terminal the ropes are secured to the mountain side, while at the lower end they are connected to heavy weights, placed in a pit, so that the tension shall be maintained.

For Smooth Travelling

There are two hoisting ropes attached to a travelling truck, or overhead gear above the car itself, which is fitted with four wheels, two running on each rope.

The steel towers supporting the track are of heavy construction, built on solid foundations. Their height varies from 23 to 97½ ft. according to the contour of the mountain side. The ropes over the towers are carried upon supporting brackets specially devised so that no jar or oscillation is imparted to the car as its wheels pass over the towers.

The travelling speed is generally 10 ft. per second, and the journey occupies nearly thirteen minutes.

The railway is electrically operated. Electricity is drawn from a neighbouring power station. Since the railway works upon the counterbalancing system, a large amount of additional power is not required. An electric motor drives a wheel, to which is coupled the cable sheave or pulley. The cable is wound round this several times. In this manner the drive is as direct as possible, and there are three independent brakes, so that the car is always under perfect control.

T he car itself is suspended from the overhead gear or travelling truck in such a way that it maintains a horizontal position irrespective of the gradient. The car is fitted with large plate-

he car itself is suspended from the overhead gear or travelling truck in such a way that it maintains a horizontal position irrespective of the gradient. The car is fitted with large plate-

IN GERMANY extensive use is made of aerial railways, both for passengers and goods. This picture shows a passenger cage in mid-

The braking system is designed to ensure perfect safety. If a hoisting rope should break there is a powerful clip which automatically grips the track, and so brings the car to a standstill. This emergency device is so powerful that during the trials, when one of the hoisting ropes was deliberately broken, the car slipped back only six inches before it came to a stop. Even if one of the track cables snapped, the brake would instantly come into operation, and after the car had been stopped it could be restarted and driven slowly into its station along the remaining cable, which is tested to withstand several times the weight of a car. This brake is not only automatic, but can also be applied by the driver, so that whatever should happen it is impossible for the car to slip out of control.

At the same time the stations are fitted with automatic and hand-

Even these safety devices are not considered to be sufficient. In the most unlikely event of the failure of all these devices, passengers can still be taken from the car. As emergency apparatus, each car carries a collapsible bag with a rigid bottom. The bag can be lowered through a trap-

The travelling speed of this cable-

Automatic Braking

The moment the car, either in ascending or descending, exceeds the speed, the automatic brake comes into action and checks the rate of travel. The authorities have also forbidden the operation of the railway during high winds. A wind-

When passengers travel on this aerial railway they will notice a complete absence of vibration or swinging of the cars. The vehicles start without any perceptible jerk and glide steadily and smoothly up and down the side of the Kohlerer Mountain. When the cars approach a station the speed is automatically decreased and the transit ends as easily as it began.

In addition to the telephone and electric lighting circuit between the stations for the transmission of the starting signals, a special telephone wire is provided for the convenience of the driver of the car. The driver is thus in continuous communication with both upper and lower stations during a journey. Should any slight mishap occur, he can immediately notify the engineers at both ends.

Another interesting example of a passenger ropeway is that of the Sestrières Pass to Monte Sises in Piedmont, Italy. This line is built in two sections, with an intermediate station. The upper terminal is situated at an altitude of 8,200 ft.

This particular aerial ropeway is a typical example of the possibilities of developing a certain district. The mountains near Sestrières offer such wonderful opportunities for winter sport that it became necessary to construct, within two years, a second aerial ropeway to the Banchetta Crest.

This particular aerial ropeway is a typical example of the possibilities of developing a certain district. The mountains near Sestrières offer such wonderful opportunities for winter sport that it became necessary to construct, within two years, a second aerial ropeway to the Banchetta Crest.

OVER THE DANUBE VALLEY. Magnificent views ot the Valley of the Danube are obtained on the Feuerkogel aerial railway in Austria. It carries passengers to a height of 5,314ft. above sea level. The lower terminal is on the banks of the Traunsee Lake.

Perhaps the most notable of the ten Austrian cable railways is the one which ascends the Feuerkogel Mountain in the Höllengebirge range. The railway soars up from the banks of the Traunsee Lake, and its terminus lies some 5,314 ft. above sea level. From the Feuerkogel the traveller can enjoy a splendid view of the Danube valley right away to the dark woods and forests of Bohemia.

Austria is the proud possessor of several cable railways, apart from the Feuerkogel line. In Carinthia, by the Ossiacher Lake, a railway has been taken 4,920 ft. up the Kanzel Mountain. At the famous pilgrimage town of Mariazell there is a wonderful cable-

Although the true mountaineer despises the cable-

That the aerial ropeway can be adapted for the transport of all kinds of loads may be seen from the large number of carriers constructed for the different types of loads. The principal characteristics of the coupling device remain the same in all systems. The hangers themselves may be differently shaped, and the carriers are sometimes represented by a cradle or double sling for carrying sacks, by chain slings for casks, by platforms for various packed merchandise, by drums for liquids and the like. Where sawn timber or logs are to be transported, two C-

The bi-

An aerial ropeway handling blocks of marble up to 20 tons is used by an English firm that owns quarries near Carrara in Italy. This ropeway is of exceptional interest from a technical point of view, and is an economic solution of many transport problems. The profitable working of marble quarries frequently depends on the cheapness of transport, and this is particularly important when quarries are located high up in the mountains, sometimes at altitudes of 5,000 ft. and higher.

SNOW-

At Carrara the difficulty lies in the fact that the Sagro valley, where the quarries are situated, lies at an altitude of 3,000 ft. and ends abruptly in a precipice of 1,500 ft. high. A ropeway had been in existence before, but its capacity was limited to loads of 6 tons. Heavier blocks had to be transported into the valley below over dangerous slipways, which were cut out on the slopes of the mountains; thirty and more pairs of oxen were required to haul heavy loads placed on sledge-

The line has a length of 5,250 ft, and the difference in level between the two terminal stations is 2,060 ft. There are four spans, the longest of which is 3,770 ft.

The bi-

Special provisions were made for the anchorage of the traction ropes. These are fixed at the top station to an iron structure, which is embedded in a single concrete block weighing 700 tons and which is keyed by reinforced concrete to the concrete foundations of the station building. The total weight of this anchorage is 2,000 tons.

In order to keep the traction ropes taut, each carries at the lower end a counterweight of 60 tons, which hangs on steel chains in a pit 60 ft. deep, hewn out of the rock. These counterweights move with the movement of the load and counteract the pressure of the load upon the carrying-

Although the plant is self-

The carriers for 20-

IN SUMMERTIME the Cable-

Another interesting type of aerial ropeway for the transport of minerals is that from Durcal to the port of Motril on the Spanish coast. The ground traversed is mountainous and rocky, and the costs of construction of a railway, or even a road for carts, would have been prohibitive. Durcal lies at an altitude of 2,560 ft. above sea level. The length of the line to Motril is 22 miles. The line is constructed on the bi-

Coupling and Decoupling

The buckets are fixed by means of an iron frame to the roller gear of the carrier, consisting of two pairs of steel wheels mounted on a balancing device.

There are three power stations for operating the sections of the line. Each station is completely fitted out with the necessary driving machinery, braking installations, tension regulators, and a special installation for connecting and disconnecting the carriers. These carriers, on arrival at a station, are automatically uncoupled from the traction rope and are pushed by hand over ropes until they reach the carrying-

There is practically no limit to the spans between terminals or standards, and distances of 1¼ miles have been reached. The two main problems facing the constructors were the design of a suitable coupling device which would have sufficient grip, and the construction of the carrying-

The subject matter of aerial rope transport is so varied and interesting that it has been possible to give only a brief survey of its principal applications and uses in this article.

The progress which has been achieved during the last few years by various constructors in England and abroad has been remarkable, and there can be no doubt that with the continuous development of metallurgical research further and still more remarkable progress will be made in this unusual method of transport.

TO THE TOP OF TABLE MOUNTAIN. From Cape Town the sightseer can quickly reach the top of Table Mountain by a cable railway ascending 2,300 ft. in one span. Each car on this service can accommodate nineteen passengers.

You can read more on “Aerial Mountain Railways”, “A Japanese Cable Railway” and “New Italian Cableways” on this website.