© Railway Wonders of the World 2012-

Sorting Goods Wagons

The Fascinating Story of Whitemoor Marshalling Yards, where Goods Wagons are Swiftly and Automatically made up into New Trains

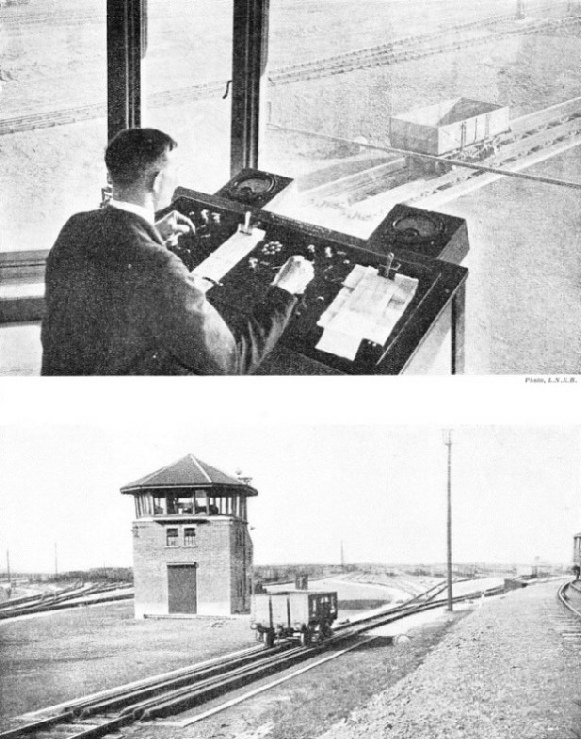

NERVE CENTRE. The operator at the control desk looks out over the down hump yard at Whitemoor.

THE need for marshalling yards arises from the obvious fact that goods and merchandise from any large industrial area has to be distributed throughout the country; and marshalling yards are the centres where train loads of these goods are sorted out prior to their being dispatched. Thus from a particular colliery a train load of coal may set out consisting of a number of wagons destined for a number of different districts. This train will be passed through a marshalling yard, where it is split up and sorted out, its individual wagons being run into different sidings. The next train in is sorted in the same manner, so that wagons destined for the same district are run into the same siding from the two trains. Each siding, in fact, is allocated to a particular district, and trains for these districts are gradually made up as more trains are run into the yard.

Speed of working is essential -

Marshalling yards consist of two main parts, the reception roads, into which trains to be sorted are run on arrival, and the classification or sorting sidings into which each train is sorted out. In hump yards, such as are situated on the LNER at Whitemoor, these two main sections are connected by a “hump”.

Wagons are pushed over this hump and are allowed to run down the other side into the sorting sidings. The height and gradients of the hump vary in different yards to suit different conditions, but the main principle is that it must be designed to give sufficient momentum to carry wagons into the sorting sidings for which they are intended.

With this layout -

In connexion with this it is interesting to note that at Whitemoor, where there are two yards, trains of seventy wagons or more are split up in the very short time of seven minutes, and about 1,500 wagons can be dealt with in each yard in one shift of eight hours. As the yards work twenty-

There are two marshalling yards at Whitemoor, one for dealing with “up” traffic and one for “down” traffic. The two yards are arranged side by side, with the main line from Ely to Spalding running between them.

Whitemoor itself is situated just outside March Junction Station. It lies conveniently between the Yorkshire and Derbyshire coalfields, the Peterborough brick fields, the fish districts of Grimsby, Hull and Goole, the fruit districts, and London and the South of England. Besides these commodities, the yards also have to handle a large amount of sugar beet during the season.

Both the yards are provided with ten reception roads, providing ample room for trains to stand while awaiting their turn for classification. The reception roads in each instance converge on to one track running down the hump into the classification sidings, of which there are forty in the up yard and forty-

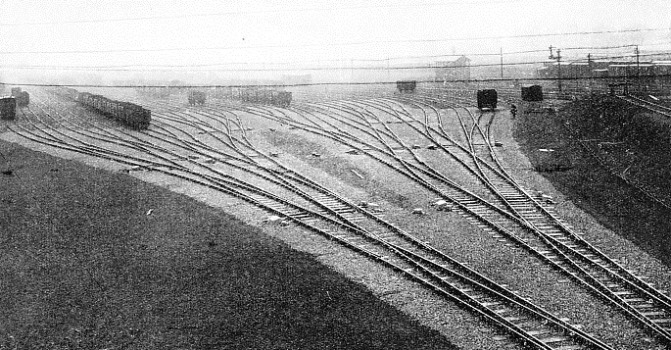

SPREADING OUT LIKE A FAN. The system of tracks at the Whitemoor down yard divides from one line to two, each of which divides again into two, and so on, to complete some thirty miles of sidings. The control tower is situated at the apex of the fan and from the wide window the man in charge commands a view of the entire yard.

The sorting sidings are arranged in “balloon” or “fan” formation. That is to say, instead of all the sidings being taken off one long lead, as is done in the “ladder” layout, the main lead first splits into two at the “king points”. These two are then split into four, the four into eight, and so on, the result being to get a number of groups of tracks with approximately the same number of sidings in each group. This has the effect of reducing the distance between the first and last sets of points, and tending to make all the sidings of equal length. Should any mishap such as a derailment occur, the yard is not blocked as it would be with “ladder” layout; all of which provides quicker sorting.

Retarding Mechanism

Some idea of the large amount of work entailed in laying down these yards may be gathered from the fact that the up yard alone entailed the excavation of some 250,000 cubic yards of material and the laying of about thirty miles of track.

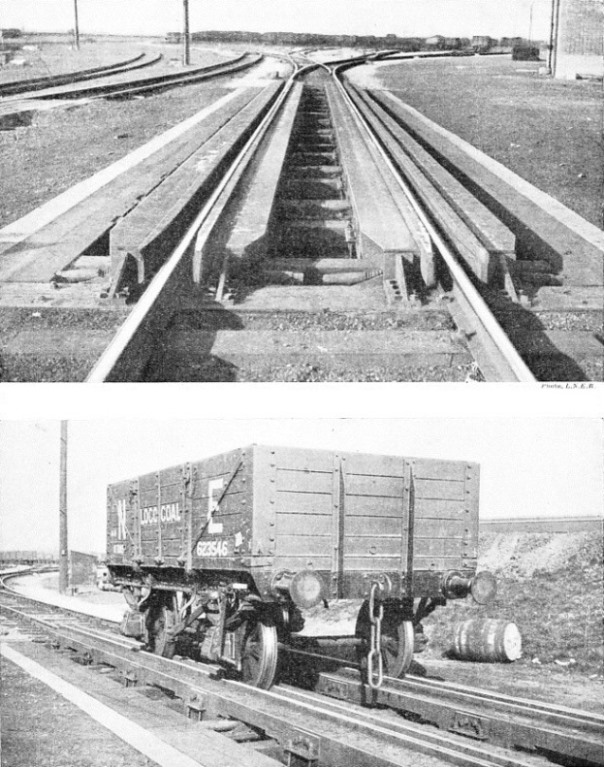

Both yards are equipped with retarders, or rail brakes, the up yard having four hydraulic brakes and the down yard two eddy current brakes. The retarders are placed at the foot of the hump on the first four -

It is necessary to brake the wagons as they run off the hump, to prevent them from colliding with the vehicles already in the sidings, and so causing damage both to the wagons and their loads. The purpose of these rail-

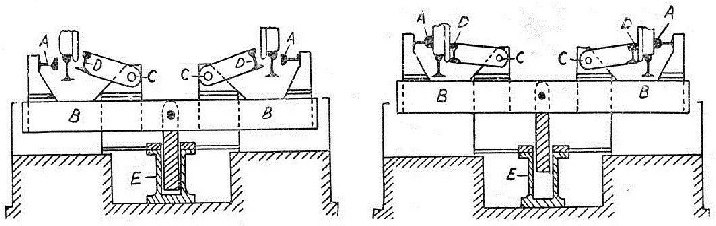

The brakes consist of four longitudinal brake beams, one on either side of both running rails. Two of these beams are fixed and the others are pivoted, as shown in the diagram of the hydraulic brake on page 252. These beams are carried on a table or platform which, in turn, is mounted on the pistons of a number of hydraulic cylinders. Thus when water at pressure is admitted to the cylinders the whole table moves upwards, so that the “feet” of the brake beams engage with the flanges of the wheels and results in the squeezing of the wheels between the brake beams. If the pressure in the cylinders is increased sufficiently the wagon will be lifted off the running rails and will ride on the feet of the pivoted beams.

HYDRAULIC BRAKES OR RETARDERS. These diagrams show a hydraulic cylinder (E), the plunger in which can be made to raise the table (BB) placed beneath the railway track. Several hydraulic cylinders are placed in a row under the table (BB), which carries fixed side-

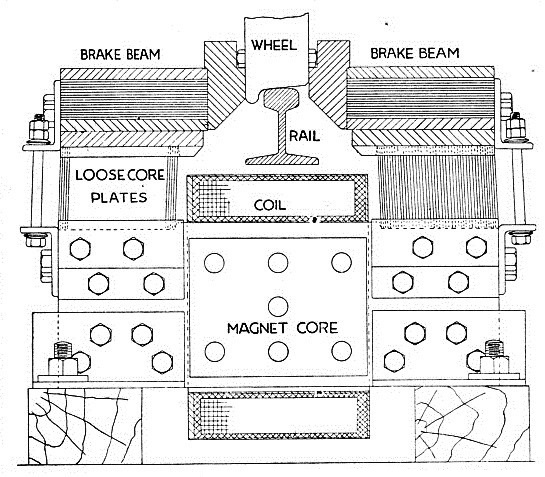

In the construction of the eddy current brake, as used in the down yard, there are four brake beams, two for each rail. These beams form the north and south poles of a large electromagnet and are mounted on packets of loose plates which in turn rest on massive iron “cores”.

THE ACTION OF ELECTRIC BRAKES working on the eddy-

These cores are spaced about 7 ft apart throughout the length of the brake, and round each is a coil which is supplied with direct current. Thus when the coils are electrically energized the whole brake becomes a large electro-

This effect can be reproduced simply by rotating a disk of any electrically conductive material between the poles of a horse-

Springs are provided at intervals along the brakes in order to pull the beams apart when the brake is de-

All the points throughout the yards are power-

Control Towers

Control towers, from which the railway staff carry out the sorting and marshalling operations, are placed dose to the “king points” from which the tracks spread out.

The control towers of each yard are similar and are built in three stories. In the bottom story is housed the power plant for the retarders -

In the down yard the power equipment consists of two glass-

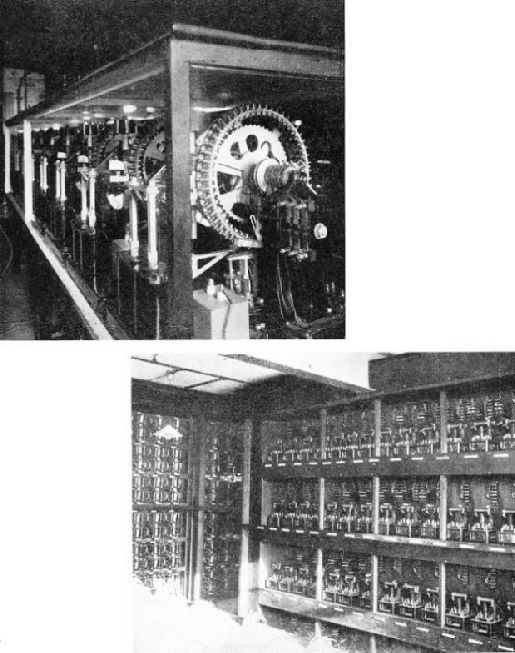

On the second story are housed the track relays, and the storage drums for automatic point setting. On this floor is also situated the operators’ mess-

The top floor of the control tower may be said to constitute the “brains” of the yard. It is from here that the traffic through the yard is controlled. Its sides are of glass, mounted at a slight angle to avoid glare, and from it a complete view can be obtained of the entire yard. The men who control the points and the brakes work in this room. In the up yard three men are employed, one to operate the switches and one for each pair of brakes, and in the down yard there are only two.

THE BRAKE BEAMS of the electro-

THE RETARDERS or rail brakes in the down yard at Whitemoor are of the electro-

CONTROLLING THE ELECTRIC BRAKE. The man in charge slows the wagons to the required speed as they travel down the yard from the hump. On the desk before him a “cut card” is placed. This indicates into which sidings the wagons will be diverted so that the brakes can be applied to bring them to a standstill.

THE CONTROL TOWER at Whitemoor down yard, which houses the mechanism by means of which the operation of the points and retarders is carried out.

When a train arrives in the reception roads, a shunter goes along it splitting it up into “cuts”. A cut consists of one or more wagons adjacent to each other which are destined to be run into the same track in the sorting sidings, and instead of uncoupling them and running them down separately, they are left coupled up to one another and are run down as one unit or cut. As the shunter goes down his train splitting it up, he makes out what is called a “cut card”. This is a sheet of paper on which are put the details of all the cuts in the order in which they will eventually be pushed over the hump. The cut card shows not only the number of wagons in each cut, and the number of the siding into which each is to be run, but also any special remarks necessary. One of these cut cards is clipped to the board on the right of the control panel, while the one on which the operation is actually working is clipped on to the panel in front of him. Several carbon copies are made of the cut card; one copy is kept in the head shunter’s office at the top of the hump, and the others are sent by means of a pneumatic tube to the control tower for the use of the operators. Thus both the point and brake operators know what is coming over the hump and can deal with it accordingly.

The point operator sits in front of a table with a sloping metal top panel which is laid out diagrammatically to represent the arrangement of the yard. On this top panel the tracks are also represented, either with aluminium paint or metal strips. Thumb switches for controlling the point machines are mounted in appropriate positions, so that when they are thrown they complete the painted, or raised metal, representation of the track corresponding to the route actually set.

Each thumb switch has three lamps associated with it, one for normal and one for reverse indication of the points, and one, situated between these two, which lights up when the track over the points concerned is occupied. Thus by means of the first two lamps the operator can tell at a glance whether the points follow the throwing of the thumb switch, and by the third lamp he knows as soon as a wagon enters and clears any particular set of points. At the extreme end of each of the diagrammatic tracks is a red lamp which lights up when the siding concerned is full, to give warning to the operator that any further wagons sent into that siding will obstruct the entry to the siding adjacent to it. Also mounted on the point control panel are thumb switches for the operation of the signals throughout the yard.

The first seven pairs of points in the yard -

The thumb switches controlling these seven pairs of points have three operating positions. Besides the usual normal and reverse positions there is a centre position which is used for automatic working. With the seven thumb switches in their centre position, the operator turns the pointer towards the group required and presses the plunger. This has the effect of setting up a route from the king points to the group required on the storage drums.

In front of him the operator has a “cut card” on which is a list of all the wagons constituting the train about to be “humped” and the order in which they will come down the hump. So that for each cut on his card the operator sets up the correct route of his storage drums. He need now no longer bother about these points, as each cut, on passing over them, automatically sets them in the correct position for the following cut. The remaining points have, of course, to be thrown by the operator by means of the thumb switches in the usual manner.

THE STORAGE DRUMS which automatically control the sorting of wagons, making each vehicle set the points for the one following it. These drums are operated by a plunger and dial on the right of the operator’s panel in the control tower.

RACKS OF ELECTRIC RELAYS, which ensure that points cannot be thrown when a wagon is passing over them, thus ensuring safety in operating and obviating derailments.

A microphone and loud speaker are placed on the cabin wall above the operator in order that he may talk with the head shunter at the top of the hump.

The control panel for the two eddy current brakes in the down yard is operated by a brakesman by means of handles, one for each brake, which he can turn from the “off” position to any one of three energized positions. Position 3 is the full energization position, and 1 and 2 intermediate positions. This operator also has a cut card in front of him and he ticks off each cut as it passes through his brakes.

The control gear of the hydraulic brakes in the up yard is different from that of those in the down yard, and here the operator has a vertical lever which he pulls towards him. The farther he pulls his lever over the greater is the braking force obtained.

Adjacent to the two marshalling yards, the LNER has a large and up-

The new power house, which was built about the same time as the down yard, supplies power for the retarders in the down yard, the pumps for the hydraulic brakes, the coaling plant and also all the lighting of the yards. This latter item is considerable, as both yards are efficiently flood-

Without an efficient lighting system it would be impossible to work the yards continuously during the twenty-

You can read more on “Goods Trains and Their Working”, “The Railway Takes All” and

“The Railways’ Daily Work” on this website.