Special Rolling Stock Must Carry the Strangest Loads

ROLLING STOCK - 1

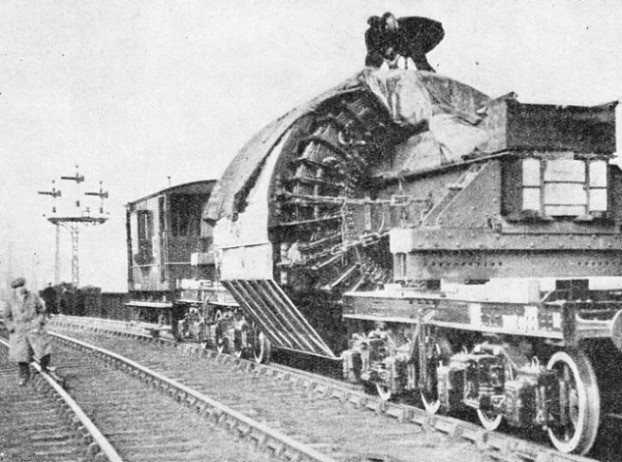

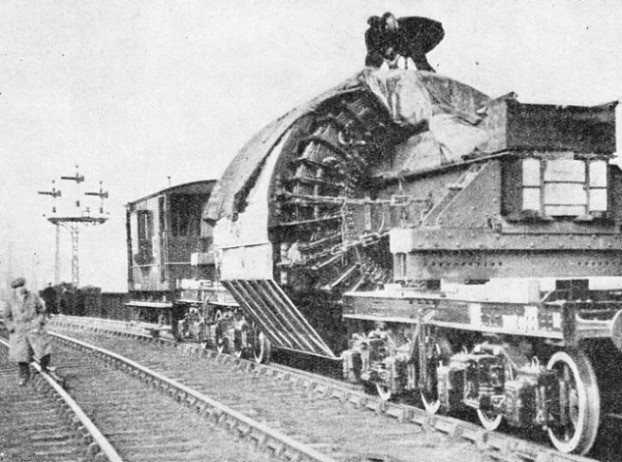

TWO SETS OF RAILS MUST BE CLEARED for out-size loads such as this huge piece of electrical machinery. It is shown here in transit from the maker's factory to the power station where it will be installed. Overhanging the six-foot way and presenting a new problem at every bridge and tunnel on the route, a load of this type can be handled only during week-ends on specially-cleared lines.

THE British railway companies are by law termed “common carriers”. This means that they are not in a position to select or refuse any particular freight, and, apart from a few exceptional instances, they have to accept whatever load is offered to them by the trader. Accordingly the railways have to build rolling stock ready to deal with not only unusually heavy loads, but also with loads which are out of gauge.

Most of the ordinary freight trains in Great Britain run at night, and more than 370 goods expresses travel after sundown between leading industrial centres such as London, Newcastle, Liverpool, Glasgow and Cardiff. Particularly bulky loads necessitating alterations along the track are mostly transported on Sundays, when the main lines are clear.

The three chief types of freight wagons used are: first, the most common type, the covered or “box” wagon; second, the ordinary open wagon, and third, the flat wagon. Flat wagons are used chiefly for the conveyance of lengthy objects such as ships’ masts and steel rails. These wagons are fitted with “bolsters”, baulks of wood and steel uprights which keep the load in place.

In this country small capacity wagons of the 10, 12, and 20-ton type are favoured. These are usually marshalled into long trains, which drop wagons at various junctions for other lines. In America the freight wagons are larger and generally loaded to their capacity, the whole train being handled unbroken over hundreds of miles.

One of the largest freight trains on record was assembled in America, when a 15,400-ton train was hauled by a mammoth compound Mallet locomotive of the 2-10-0 x 0-10-2 type for 125 miles between Victoria and Sewall’s Point. If a British train had undertaken to haul this stupendous load and the 20-ton wagons had been used, 573 of them would have been required and the length of the train would have been over two miles.

Wagon on Thirty-Six Wheels

The British railways, although they do not have to deal with such immense loads as this, have built some high-capacity freight wagons for special purposes. The largest freight wagon in Great Britain has no fewer than thirty-six wheels, and can carry a concentrated load of 160 tons.

Among the queer jobs handled by the railways has been the conveyance of entire farms. Transporting a farm may include not only the agricultural implements, such as motor tractors and haymaking machines, but also the whole of the livestock.

Special rolling-stock cattle wagons are used for the animals. These are provided with movable partitions giving either large or small divisions as required. The cattle have to be closely packed together so that they shall not be jerked off their feet or bumped against the sides of the train as it. starts or stops, with the risk of broken legs.

For the farm horses the usual “horse-box” is used, and great care has to be taken in conveying these animals to their new homes. But the removal of domesticated animals, a difficult enough task in itself, fades into comparative insignificance when the railway is called upon to transport a party of 70 lions, which once happened on the Southern Railway. The 70 animals occupied 15 cages, each weighing about 5 tons, and waited in the hold of a ship at Newhaven for the railway to convey them to the circus at Olympia.

The cages from the ship’s hold swung ominously in mid-air before coming to rest on the flat wagons, and caused the railwaymen considerable anxiety. Once, however, the cages had been successfully lowered to the trucks the subsequent journey passed off smoothly enough.

The Great Western Railway once tackled a similar proposition when it undertook to transport an entire menagerie, comp-rising tigers, leopards, lions, bears, monkeys and elephants. The whole consignment was taken to its destination in sixteen “crocodiles” - “crocodile” is the telegraphic codeword for a type of long, low well-truck - two “pythons” - covered carriage trucks; and two “scorpions” - open carriage trucks.

120 TON “CROCODILE” WAGON of the Great Western Railway. The wagon carries its load distributed over 24 wheels, and is designed to meet the needs of transport for exceptional loads, including unusually bulky or heavy goods.

“Crocodiles” are more generally used for awkward loads of heavy machinery. They are flat wagons built with sunk-in centres, hence their more technical name, “well” wagons. The load is placed in the “well”, to give sufficient head-clearance when the train is passing under bridges and through tunnels.

Quite recently the Southern Railway carried out the difficult enterprise of moving ten rotary kiln sections, each weighing 47 tons 12 cwt, with the aid of “crocodiles”. These remarkable vehicles have also made possible the transit of ship’s rudders from the foundry to the dock.

A rudder of the S.S. Aquitania was conveyed on one of these bogie well-wagons, a type of vehicle very suitable for such bulky loads. A propeller for the Berengaria, 13 ft square and 18 ft in diameter, was also taken to its destination by a well-wagon.

The largest railway wagon set to be found in Great Britain is on the London and North Eastern Railway Company’s line. This is the 150-ton cantilever set, used principally for the conveyance of such freights as electrical machinery, anvil blocks, ingot moulds and other objects of exceptional weight concentrated into a small compass.

A 226-ft Wagon

The set consists of first a 20-ton trolley wagon to carry the balance weight box at the leading end; second a 60-ton flat wagon to support the cantilever at the loading end; then a 110-ton “Weltrol” wagon with 24 wheels, and 83 ft 2 in. in length, which has the load resting upon it. Next, carrying the cantilever at the trailing end, comes a twelve-wheeled 60-ton flat wagon, added to which there is a 20-ton trolley wagon carrying the balance weight box.

The 110-ton “Weltrol” wagon is capable of carrying self-contained loads up to no tons, but by fitting it with cantilever beams and making up the set in the order described above, loads of 150 tons can be conveyed. The set is supplied with special drawbars between the 110-ton well trolley wagon and the two 60-ton wagons, making the total length of this colossal vehicle 226 ft 2 in.

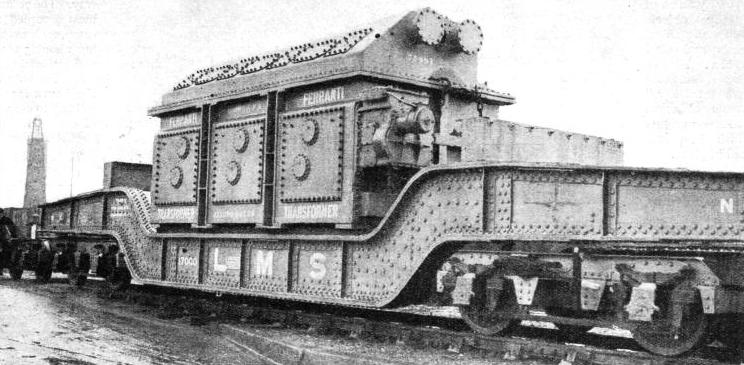

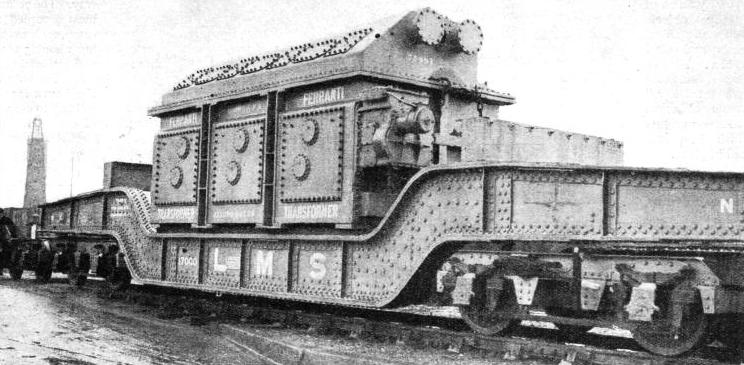

Another outstanding freight set for exceptional loads is the ultra-modern 70-ton transformer set, with 16 wheels, a tare weight of 42 tons 10 cwt and a length of 65½ ft. This has been specially designed for the conveyance of transformers. The method of loading is to suspend the transformers from the top of the girders on the set, which can be adjusted according to the size of the load to be carried. The girders are detachable, and may be released from the bolster at one end in order to enable them, along with one of the wagons, to be withdrawn longitudinally free of the transformer.

Another monster freight wagon also belongs to the London and North Eastern Railway and is used chiefly for the purpose of transporting bricks from the great brickyards at Fletton near Peterborough. These wagons are able to take on board some 17,000 to 20,000 bricks simultaneously, according to the sizes of the bricks. The length of this type of wagon is 41 ft and it can carry 50 tons.

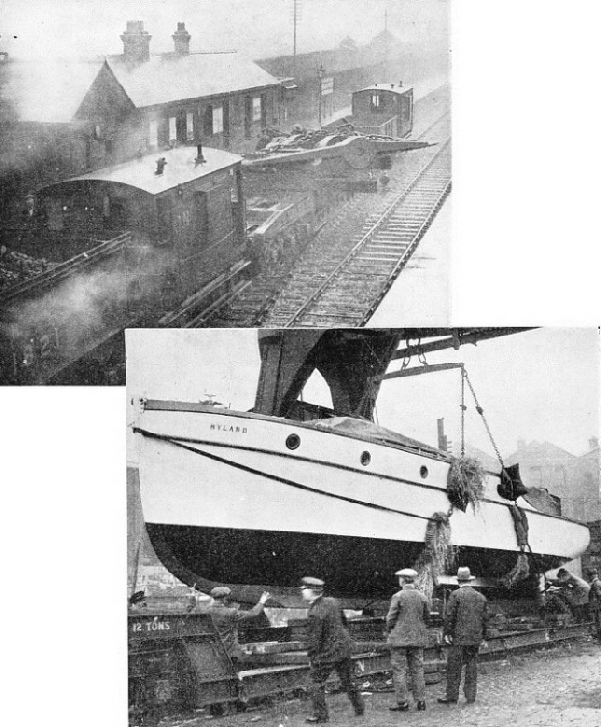

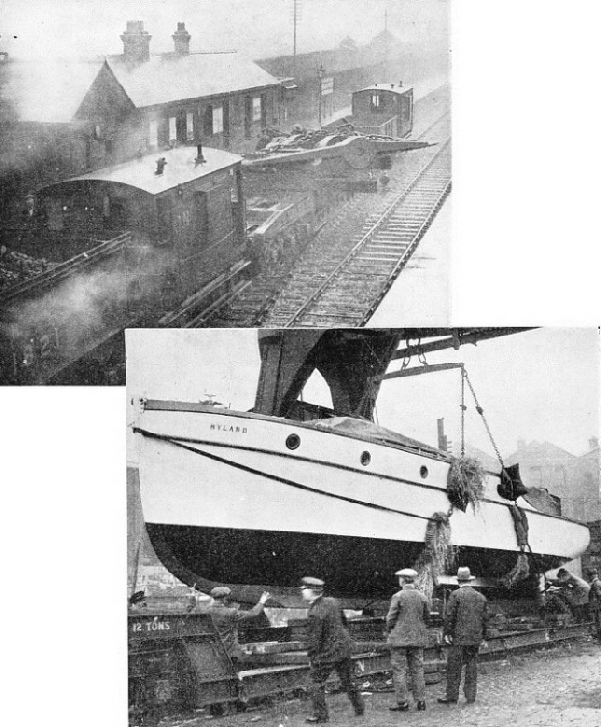

Among the queerest loads taken by the railway was the recent transport of two motor cruisers, one of which was brought from Goole and the other from Yarmouth to London. These two vessels, both of considerable bulk required very careful handling, but reached their destination on time schedule and in safety. The cruisers were taken from the railway depots by railway trailers and tractors to Olympia.

THE CONCENTRATED WEIGHT of this enormous transformer demands the use of special trucks, to distribute the load over many wheels. In order that bridges may be cleared the truck is of the well type, in which the load is placed as close to the lines as possible. The weight of this transformer is 93 tons, that of the special wagon alone being 47¾ tons.

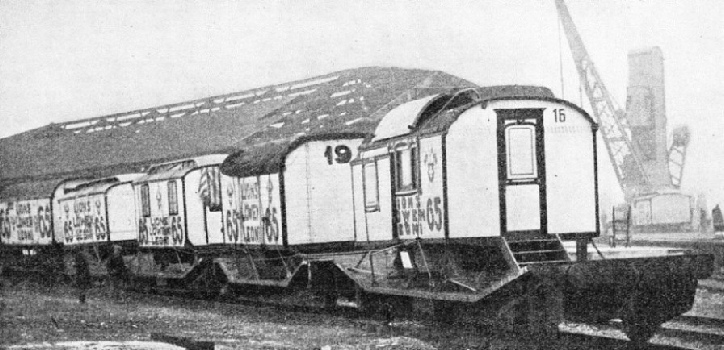

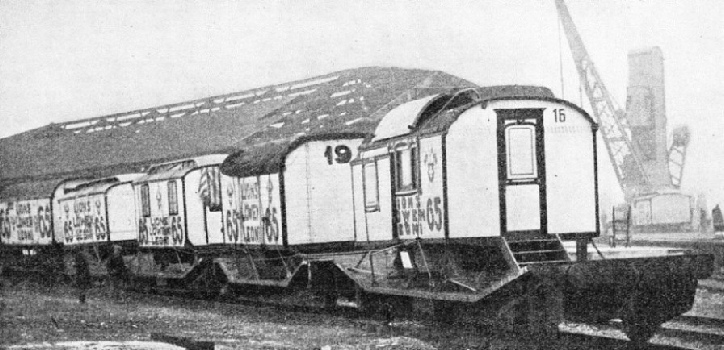

This door-to-door service represents one of the recent developments in the railways’ freight departments. In most instances, special wagons, called “road-rail” containers, are used. Various types of containers built to be carried with equal facility on a rail wagon chassis or on a road vehicle can be seen on all the British railways to-day. The container is brought to the consignor’s door, where it can either be lifted off, if suitable appliances are available, or left on the road vehicle, for loading. The container, after having been filled by the consignor, is brought into the station and lifted bodily in one operation on to the wagon.

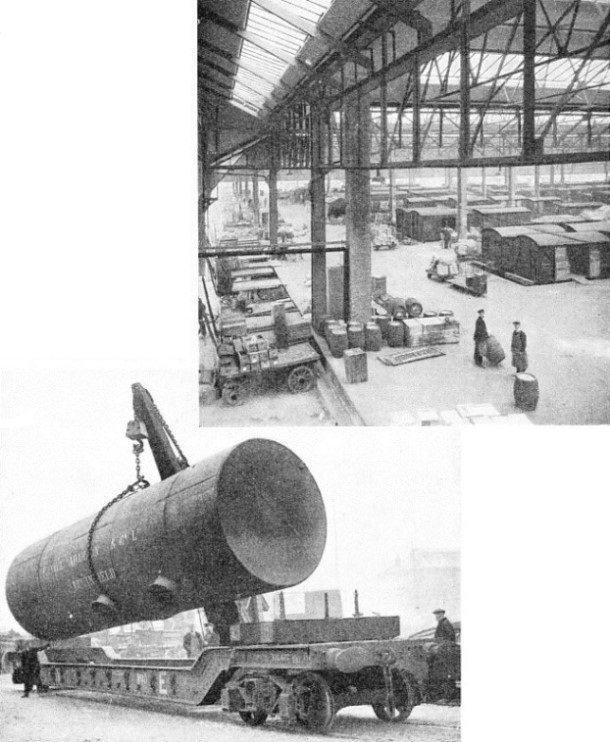

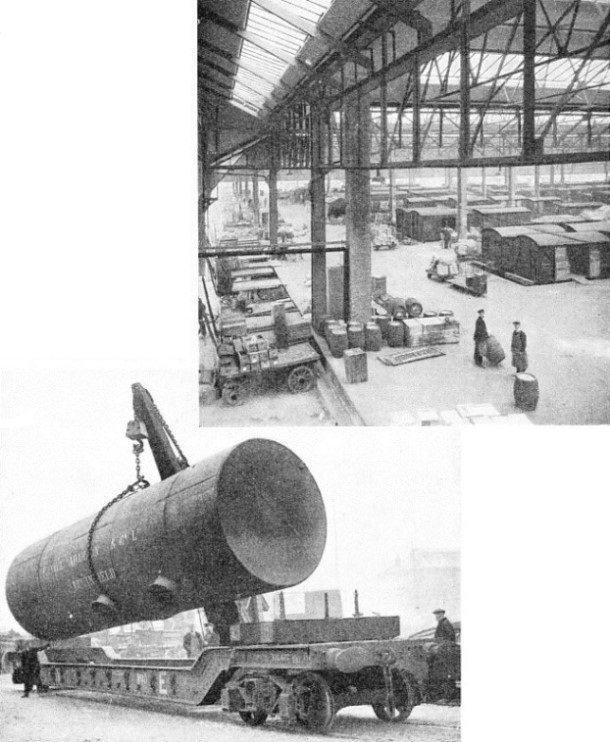

THE LARGEST covered goods station in the world is at Temple Meads, Bristol. a typical view of which is shown here.

PROBLEMS OF BULK are sometimes associated with those of great weight. The carrying of a huge boiler, as shown in the illustration below, provides an instance of this kind. The men who undertake this work are specially picked from the engineering staff, and the preliminaries involved in measurement and calculation along the route are offen far more exacting than the transport of the load itself. A cylindrical load requires particularly secure attachment to the bogie wagon, to obviate the danger of its working loose during transit. Heavy-duty cranes are provided to handle the load at each end of the journey.

At the receiving station it is lifted by a crane on to the body of the road vehicle, the contents remaining undisturbed and untouched from the time they are put into the container to the moment it is opened by the consignee. The advantages of this system are manifold, but the chief are that the transport from factory to destination is carried out without handling, the risk of damage is greatly minimized and much time saved.

A further class of freight which offers the railway companies some difficult problems is that of perishable goods. For the conveyance of bananas, for example, special wagons have to be built. A large proportion of the banana traffic is handled by the London, Midland and Scottish Railway tapping the Avonmouth Docks, near Bristol, and also the Garston docks, near Liverpool.

By means of a circular moving belt fitted with pockets, into which the banana stems are put by hand, the fruit is taken from the holds of the cargo ship. Once out of the ship and on the wharf-side, the fruit is taken from the pockets, next being placed on to a mechanical band running alongside the rail vans, into which the stems are finally loaded and carefully packed by hand.

When the bananas have been landed it at once becomes necessary that they should be fully ripened. Up to this point they are still green - special refrigerating apparatus on the ships having kept them unripe. Once ashore, and about to be put on the market, they are allowed to ripen. In the winter the banana vans are supplied with steam-heating to stop cold from hindering the ripening of the fruit, which would be valueless if unripe. So important is this that the vans are inspected before the train leaves to ensure that there are no faults in the heating, and to make certain that the vans have a sufficient and uninterrupted supply of steam passing through them.

A SHIP’S RUDDER is a traveller that requires special consideration, and to carry the one shown in this picture the engineers resorted to “wrong line” working, the special freight train travelling on the right-hand set of metals, instead of keeping to the left, as is usual in this country.

THE LAND TRAVELS OF A MOTOR- LAUNCH must be carefully arranged, since the hull of the vessel is fragile. Sacks of straw and large fenders are used beneath the slings when it is necessary to lift the launch. The position of the slings is care-fully adjusted to avoid any possibility of straining the structure, a danger which must constantly be guarded against until the boat has been placed in the water. A load of such dimensions will doubtless necessitate a detour by the train in order to avoid bridges and tunnels along the route.

From the diversity and frequent awkwardness of much of the freight to be carried, the multitude of problems confronting the Goods Traffic Control departments will be readily appreciated. Nevertheless, freight time-tables, similar to the ordinary passenger time-tables are made out for the benefit of the operating staff, while schedules of work for engines and crews are also published.

These programmes are not strictly adhered to owing to fluctuations in traffic. It would, for instance, be useless to run long goods trains with semi-full wagons. The modern method of conducting freight movements is to centralize all information regarding the amount of freight to be conveyed, the available locomotives, the train crews free and the number of wagons on hand. This gives the traffic controller an opportunity to ascertain the most economical way of operating the combined traffic.

A skilled controller is able to make great savings in engine power, in operatives and in the movements of both full and empty wagons. Half-loaded trains can be halted at various places, while very lightly loaded workings can be cancelled and two trains made up in one.

It may be amusing for the layman to see wagon after wagon hauling such queer and heterogeneous objects as elephants, a lifeboat, a circus cannon - utilized to shoot out its owner at propitious moments - and a twenty-ton boiler, it is a serious matter for the railways, calling for careful consideration and foresight.

The transport of freight - not the conveyance of passengers - constitutes the most important concern and chief source of revenue of railway companies. For instance, in England, nearly two hundred million gallons of fresh milk are carried on the railway annually, together with hundreds of thousands of tons of fish and meat and fruit. These are special items, quite apart from the general heavy merchandise such as timber, coal, steel and iron.

When the number and variety of goods to be handled, from pins to elephants, are considered, it will be easily realized that certain articles of unusual bulk and weight present the authorities with some difficult problems. All “outsize” loads, or loads demanding special attention, are usually handled by the Chief Engineer’s department. This department has to decide what route and what truck alterations are to be made in moving a particularly awkward load.

Giant Electric Generators

Quite recently the firm of Metropolitan Vickers completed the casing of the most powerful electric generator in Europe. This casing weighed 42 tons, with a length of 24 ft 4 in, a height of 11 ft 4 in and a width of 12 ft 6 in. The problem was to have this great piece of machinery transported to South Lambeth, where it was to be delivered to the Central Electricity Board’s Battersea Power Station. The railways undertook the task and the overcoming of the difficulties connected with this very exceptional load. And difficulties there were, for although the railways had conveyed even heavier and longer freights, nothing of such a generally awkward bulk had been carried previously.

This gigantic casing had to travel 284 miles before reaching its destination, and in the course of the journey cross the tracks of four main-line companies. For the larger part of the route the casing went over the Great Western Railway Company’s metals. On this company’s line the casing exceeded the gauge limit for width by almost three feet, while it just cleared the height gauge by two inches, the top being 13 ft 4 in above the rails when hoisted upon a bogie well-wagon.

The well-wagon on which the casing was carried was sandwiched between two goods guards’ brake vans, which, together with the locomotive, represented the special train. Before this train began its journey, however, considerable care and foresight had freed the route of obstacles. The engineers had to ascertain whether the exceptional load would clear various bridges, station platforms, signal posts, signal wires, water replenishing devices, tunnels and countless other railway erections close by the track.

Plans and diagrams of the route were carefully scrutinized to discover where real trouble would be likely to occur. To make doubly sure, however, that the casing would clear everything safely, a coach fitted with a frame of the same size as the casing was run over the suggested route, accompanied by a number of the engineering staff. The casing was to be brought from Manchester to Crewe by the London, Midland and Scottish Railway. At Crewe the Great Western would be responsible for it until near London.

SIXTY-FIVE LIONS, bad-tempered from a sea-voyage, were moved by the railway from Southampton to Olympia, London, without mishap, constituting an unusual load. When a complete menagerie is moved—as often happens—the elephants require special attention, but the most difficult zoological specimen from the transport point of view is the giraffe, whose long neck is a continual source of anxiety.

Despite the fact that engineers have often had to practise their ingenuity with outsize loads, and through their experience are capable of squeezing loads through the narrowest sections, they could not induce the casing to pass through the Wolverhampton Tunnel. The solution lay in a forty-one miles digression, the roundabout route being from the Oxley Sidings via the Kingswinford branch line to Kidderminster, Worcester, Evesham and Stratford-on-Avon The London-Birkenhead main line was to be rejoined at Hatton.

Apart from “wrong-line working” - when the train was running on the “down” line instead of the “up” - the special train travelled on the main line, but the set of lines on either side of it had to be kept clear all the way. When any serious obstacles appeared, or when the gauge would be cleared only by inches or fractions of an inch, the speed dropped to three or four miles an hour, and throughout the journey a strict limit of twenty miles an hour was enforced. Care was also taken to keep most of the station platforms clear, because the casing overhung by some eighteen inches.

The actual transport operations occupied two week-ends. The first stage was the conveyance from Trafford Park, Manchester to Old Oak Common. three miles from Paddington Station, London, where it was run into the yard to wait until the subsequent weekend. This part of the journey presented the railway engineers with some acute problems, as the latter half of the journey brought the load into the suburban area. The last part of the casing’s journey was scheduled to begin early the next Sunday, before dawn the inspectors and engineers who had the task of seeing the load to its destination at South Lambeth were assembling: they came from the companies concerned. Introductions were brief. By torchlight the load was carefully examined to see if all was still securely and safely in place.

At five minutes past five the special train hauling its curious freight ran slowly across the main lines and made its way towards the tunnel that would take the train on to the West London track. As the engine drew the casing near the tunnel entrance, a powerful torch was flashed round the top of the load and then directed on to the tunnel’s arch. There were a few inches to spare. The “all-clear” was given and the locomotive moved on again.

Seven miles from South Lambeth the special came to another halt - this time to wait while two sets of lines were cleared. Again and again as likely obstacles were approached the engine stopped. From the guard’s van the accompanying officials kept a constant look-out, anxiously calculating in advance whether the load would clear the various wires, posts, discs, signal-boxes, roofs and platforms. They had to maintain a constant vigilance on all sides and also above.

A LEVIATHAN OF THE LINE. This is the largest railway wagon set in Great Britain, having a total of fifty-six wheels. It consists of five units, and can carry a concentrated weight of 150 tons, being arranged on the cantilever principle, with the load in the centre and balance weights distributed at the ends. Its total length is 75 yds 1 ft 2 in.

At Addison Road the line had been previously moved to one side to afford the necessary space. A batch of men standing near the bridge, armed with picks and shovels, ready to replace the track into its correct position, watched the casing go slowly past.

More excitement came at Earl’s Court, where the train had to be taken over a “wrong” line once more. As a precaution, an inspector escorted the load.

Soon after this the casing reached Chelsea Station. Here flares were burning, and more men stood by after having slewed the track almost one foot out of alignment. As soon as the “special” had passed the permanent way men were moving the line back so that normal running could begin again almost immediately.

A few minutes later a tug’s siren announced the proximity of the Thames. Then the great chimneys, each 327 ft in height, of the Battersea Power Station, the ultimate home of the generator casing, came into view; the end of the adventurous journey was at hand, but there were still two or three obstacles to be surmounted.

It was at this point that the Southern Railway’s officials took over the command. The train crossed the railway bridge over the Thames, the load just missing a partly dismantled signal, and then passed through an over-bridge. After this came another obstacle - the low bridge No. 331 that carries the South Western main line section of the Southern Railway. All traffic over the bridge had to be held up while the load passed beneath. This extra precaution was taken, although according to previous measurements it had been calculated that the load would clear the bridge by 1½ in.

It was exactly half-past seven on that Sunday morning when the locomotive hauling the giant casing snorted proudly up an incline into South Lambeth. A shunter, a solitary policeman and two other early risers alone greeted the exceptional load as it drew in at long last under the aegis of the tall twin chimneys.

The bogie well-wagon had then to be returned to its own particular yard, the guard’s vans to their sidings, the locomotive to its shed, but the giant casing rests in its place. The railway had quietly and unobtrusively performed a modern miracle. And a few hours later, when all the track alterations had been readjusted, there was no evidence to convince a disbeliever, except a few figures in a book and a few letters in a file tucked away in some office corner.

The railway carries on; there are other jobs, just as big, always coming along; they will be performed with the same efficiency. That is the wonder of railways.

You can read more on “Goods Trains and Their Working”, “The Railways’ Daily Work” and “Sorting Goods Wagons” on this website.