© Railway Wonders of the World 2012-

The Union Pacific Streamlined Express

Flying on land from the Atlantic Coast to the Pacific Coast

RAILWAYS owe their existence to the horse -

Two such sweeping statements obviously need explanation. Taking the first -

Next followed over a century of progress and improvement, culminating in the great luxury expresses of to-

Both the motor-

Railway companies throughout the world are now able to make the best use of their smooth and level tracks by providing the travelling public with an entirely new type of passenger train.

Particularly interesting expresses built on the new streamline principle are in service on the Union Pacific Railroad in the USA.

Particularly interesting expresses built on the new streamline principle are in service on the Union Pacific Railroad in the USA.

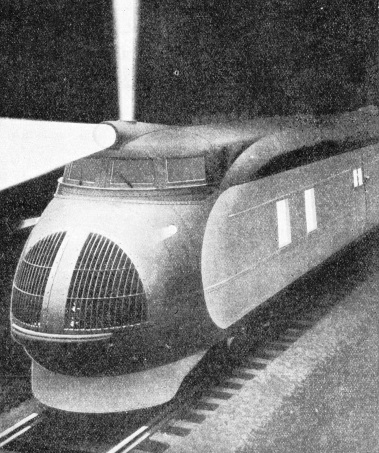

AT NIGHT TIME the streamlined train lights the way with a powerful electric searchlight, in addition to which a vertical beam of light gives ample warning of approach to motorists and pedestrians at level crossings and the stretches of unfenced track found on American railways. These headlights will penetrate fog, dust and snow, providing additional safety during high-

The first of these trains comprised three carriages, electrically driven, current being generated by a 600 hp internal combustion engine in the leading coach. Only 500 hp is required to propel the train, which weighs 85 tons, at a speed of 90 miles an hour with a load of 116 passengers, its crew and some 11 tons of mails and luggage. A typical American steam train of ten coaches, weighing 1,000 tons, would require 4,500 hp to attain the same result.

The light weight of the new train was obtained by a radical departure from conventional construction, aluminium alloys being substituted for steel, this giving equal strength with only one third of the weight.

The streamlined design was determined as the result of a series of scientific tests with scale models in a wind tunnel -

In place of the usual steel underframe of most passenger coaches, which carries the superstructure and the load, each carriage in the new train is tubular in shape and the entire coach body forms a deep, stiff beam, thereby requiring a minimum of material for a given strength. The coach bodies are composed of two principal structural elements, namely, the extruded aluminium alloy frames, in combination with the aluminium alloy plates forming the outer and inner sheathing. Between these sheaths is a two-

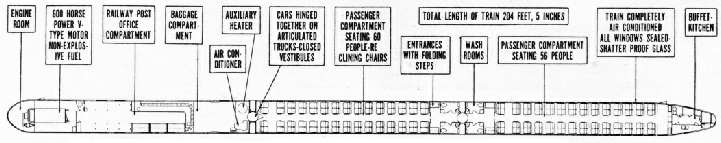

The train has a total length of 204 ft 5 in, the power, mail and baggage coach being 72 ft 8 in long; the middle coach is 59 ft 10 in long, the third coach measuring 71 ft 11 in.

The design of the new train is such that it hugs the rail in the same manner that a low-

Articulation between the body units of the train was adopted as best suiting the requirements for high speed and smooth riding. In brief, articulation consists in having one bogie-

There are four wheels on each of the four bogie-

The main power plant of the train consists of an internal combustion engine directly connected to a generator supplying electricity to two motors mounted on the forward bogie of the first coach. The engine is of the 12-

The electric generator, rated at 425 kilowatts, supplies power for two traction motors, each of 300 hp, one being mounted on each axle of the front bogie-

In addition to the main generator there is an engine-

The entire power plant, including all auxiliaries, storage batteries, accessories and apparatus, weighs approximately 20 tons. By way of contrast, a Union Pacific steam locomotive, used in regular passenger service, weighs 316 tons.

The entire power plant, including all auxiliaries, storage batteries, accessories and apparatus, weighs approximately 20 tons. By way of contrast, a Union Pacific steam locomotive, used in regular passenger service, weighs 316 tons.

The internal combustion engine of the train uses heavy fuel oil instead of petrol or other spirit, so that all risk of accidental explosion is removed. The fuel tanks, with sufficient capacity for a 1,200-

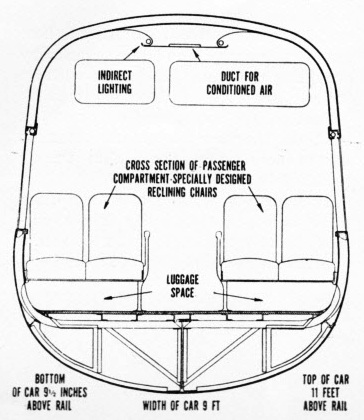

This diagram shows the tubular construction of the streamlined train.

The super-

In conjunction with the pneumatic system is an electric circuit actuated by contact points on the driver’s brake valve and operating a magnetic control device on each pneumatic brake valve. This not only synchronizes but also accelerates all brake applications and releases.

An important feature of the super-

The super-

By the use of the decelerometer control it is possible to stop, even from exceptionally high speeds, in a shorter distance than is possible on slower steam railroad trains and without the slightest discomfort to the passengers.

A plan view showing how the three coaches are hinged together, so rendering the train flexible for negotiating curves.

The motorman, or driver, with all his controls and necessary instruments, is provided with an elevated cab above the rounded nose of the power coach. The cab is separated from the main engine room by a metal partition with a door that opens directly on a platform overlooking the power plant. From his elevated position the motorman has a much greater visual range than does the driver of a steam locomotive. His outlook includes the entire area on both sides and in front of the train. He is also removed from the noise of the engine room.

The main operating controls in the cab consist of first, the throttle, which governs the speed of the engine itself, much as pressure on the accelerator on a motor-

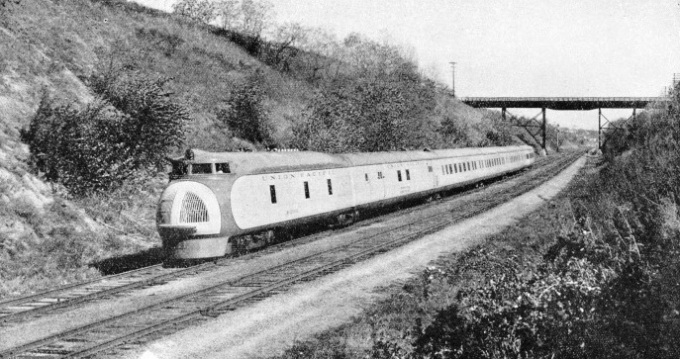

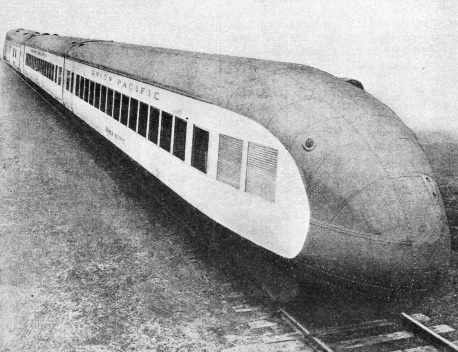

A RECORD RUN. The first American streamlined train to cross the continent from Los Angeles to New York in just under 57 hours at an average speed of 62 mph. This train is of the six-

The motorman, when the train is running, is seated on the right side of the cab. In a corresponding position on the left side of the cab is a dual set of the controls for the use of a second man.

The brake valve is equipped with a “dead man” handle and pedal, necessitating the motorman’s keeping either a hand or a foot on this control while the train is moving. If for any reason the motorman accidentally relinquishes control, there is immediately an automatic closing of the throttle and application of the brakes.

Electric signals afford communication between the train crew and the motorman. A powerful horizontal headlight of special construction is streamlined into the roof of the motorman’s cab. Immediately behind this headlight is an additional headlight with a 10-

Filtering the Air

On the instrument board before the motorman is mounted a sensitive speedometer, electrical instruments, oil-

The side doors of the train, when closed, form a part of the smooth exterior contour of the coaches. The doors are interlocked with steps that fold up when the former are closed. A flush trap-

The new train is fully air-

The air conditioning is accomplished by the distribution of filtered air, cooled or heated as desired, through a system of ducts by means of power-

There is a duct carried throughout the train on each side below the floor level and a central ceiling duct which forms a part of the interior design. A radiator outlet is adjacent to each seat and air is expelled through a corresponding outlet in the ceiling duct so that a definite circulation is obtained at each seat unit. The windows are sealed in rubber and are set practically flush with the outside of the coach to minimize wind resistance.

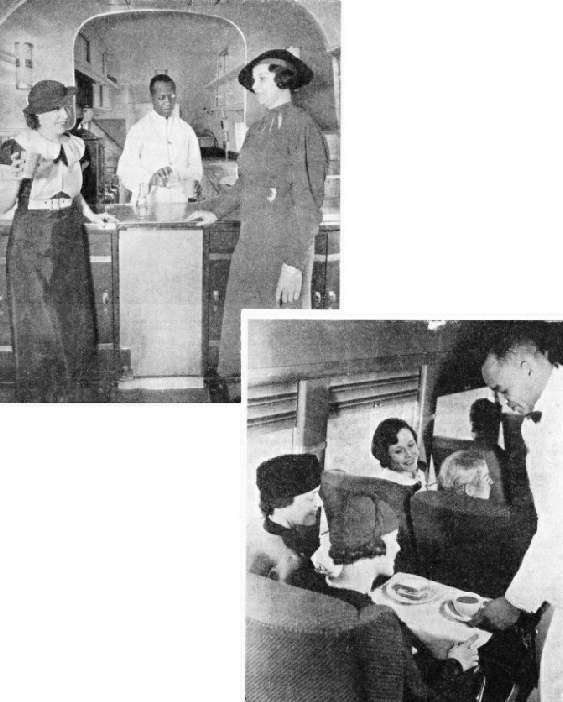

THE KITCHEN BUFFET, which is built into the end of the last coach of the train. The traveller can obtain occasional refreshments at the counter.

LIGHT MEALS are also prepared in the train kitchen, and passengers are served on little trays which can be attached to the seats, as seen right. The trays can also be used for writing and are readily removable when not required. The backs of the seats are adjustable, and foot-

The lighting system is indirect, the electric globes being concealed in an aluminium panel running the entire length of the coach ceiling. Light is reflected on each side against the curved ceiling, so that illumination is evenly distributed for reading. The lights are so arranged that three intensities are obtained, the lowest intensity being for night lighting while passengers are sleeping.

The interior decoration is of striking but simple design. The colour scheme is blue, shading down progressively from nearly white at the top of the vaulted ceiling, through the lighter shades of blue to a dark blue colour below the window sills. Horizontal lines of aluminium show between the different shades of blue, and trimming on the chairs is also of aluminium. Window sills are of black bake-

The new train will seat 116 passengers, 60 in the middle coach and 56 in the last carriage. The seats are arranged in pairs on either side of the aisle, each seat having individual adjustment to four positions, the lowest being for sleeping.

The seats are equipped to hold trays for taking meals or for writing. The space beneath the seats is kept clear to provide storage space for baggage, the overhead baggage racks of the conventional train having been eliminated.

A novel feature is the buffet kitchen which is built into the tail of the last coach. This is replete with space-

Meals are served from a special dinner-

The dishes in use on the train, instead of being china, are made of special composition, very light in weight, and gaily coloured.

It is noteworthy that the total weight of the dining service of the train is only 189 pounds, against a weight of 530 pounds for a similar service in china, a saving of 341 pounds.

The floors of the coaches are of aluminium alloy plates, built into and forming a part of the structural work. These plates in turn are covered with a composition flooring on top of which the final flooring of cork tile is laid.

SPEEDING ACROSS A CONTINENT. America’s first Diesel-

A very important and interesting feature which has been introduced into the construction of the train is the use of safety glass for all windows.

This glass is impervious to the ultraviolet rays of sunlight, so that one can sit in the sunlight in the train all day without experiencing the discomfort of sunburn. The windows are sealed with rubber and are practically flush with the exterior contour of the train, to reduce wind resistance. The windows in the driver’s cab are also of safety glass and are equipped with wind-

Two wash and toilet rooms are built into the ends of each coach. The most modern type of sanitary equipment and fittings are installed. The wash-

In the women’s toilet-

The luggage compartment is immediately behind the mail compartment and takes up the remaining space of the first car. It contains the usual facilities for the careful and safe handling of luggage.

Doors of both the mail and luggage compartments are flush with the exterior of the train while it is in motion.

The mail and luggage doors are very wide, and are opened by a special device which first moves the entire door inward several inches and then slides it open lengthwise of the train on the inside. Windows, also of shatter-

The tests carried out with this tram were rigorous in the extreme, a tour of some 13,000 miles having been accomplished with very gratifying results.

The tests carried out with this tram were rigorous in the extreme, a tour of some 13,000 miles having been accomplished with very gratifying results.

THE CONTROL CABIN of the Union Pacific Streamlined Express. This cab, situated in the front of the train, contains all the control mechanism. The lever in the immediate foreground is the throttle of the Diesel engine, and at the right of the cab is placed the air brake control. The motorman sits between these controls with the instrument panel before him, a clear view through the safety glass windows being ensured by large windscreen wipers.

The route which was followed took the train over the rails of fourteen different American railroads in twenty-

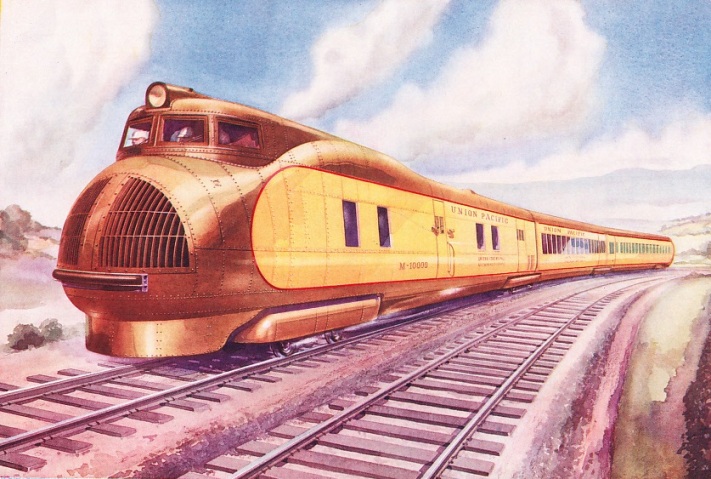

The first train built to the new design proved so successful that the capacity of a second train has been increased to six coaches, three of these being Pullman sleeping cars. The power unit is a 12-

The 900-

The larger train resembles the first three-

Aluminium is, of course, used tor the tubular body-

The special braking arrangements of the first train are also applied to the larger express, and tests have shown that it can be stopped in 900 yards, even when travelling at 90 miles an hour. A steam train at only 60 miles an hour requires a run of 1,000 yards before the application of brakes will bring it to a standstill.

The Pullman cars in use have been specially designed for the streamline trains and constitute a great advance in luxurious travel. Two of the cars on the express each contain 10 sections (20 berths), with one compartment and one bedroom.

The other type of Pullman has eight sections with a compartment and bedroom.

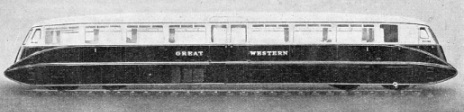

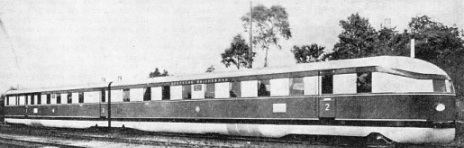

STREAMLINING IN BRITAIN. The Great Western Railway has put into service a special car designed to run at 60 miles an hour and weighing 20 tons. The under frame is 60 ft long, with a width of 8 ft 2 in. The car is carried on two 4-

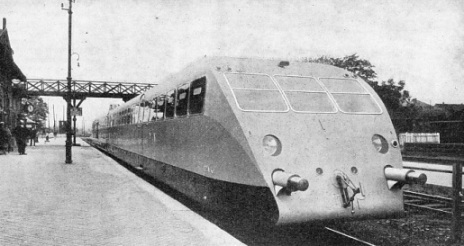

THE ”FLYING HAMBURGER", the fastest train in regular service in the world. Comprising two articulated coaches with seating accommodation for 102 passengers, the train covers the 178 miles between Berlin and Hamburg at an average speed of 77 miles an hour with a maximum speed of 99 miles an hour. The power unit consists of two 410 hp Diesel engines, driving generators supplying current to the electric motors of the train.

THE ”FLYING HAMBURGER", the fastest train in regular service in the world. Comprising two articulated coaches with seating accommodation for 102 passengers, the train covers the 178 miles between Berlin and Hamburg at an average speed of 77 miles an hour with a maximum speed of 99 miles an hour. The power unit consists of two 410 hp Diesel engines, driving generators supplying current to the electric motors of the train.

HIGH-

An interesting feature is the provision of two sections in each sleeping coach which are six inches longer than normal for the accommodation of passengers above normal height. Each berth, both upper and lower, has individual wash-

The Pullman cars are also provided with separate dressing-

The Pullman cars are also provided with separate dressing-

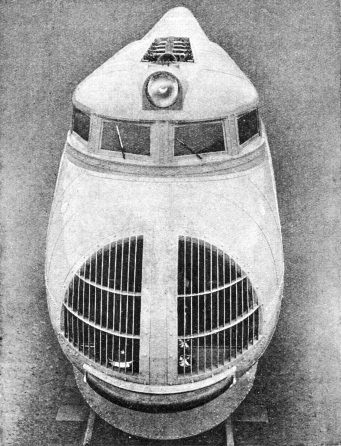

THE ROUNDED NOSE of the Union Pacific streamlined train. The two openings covered by grille work are the air intakes to the engine radiators placed just below the engine-

This remarkable train broke all railway records in October, 1934, when it covered the 3,259 miles between Los Angeles, California, and New York in 56 hours 56 minutes. The time for this journey by the quickest steam trains is 84 hours.

An average speed of 82 mph was maintained over the 508 miles from Cheyenne, Wyoming, to Omaha, Nebraska.

It was on this section that a maximum speed of 120 mph was claimed, though this was based on the approximate statement that two miles were covered in one minute. From Los Angeles to Chicago, including the transit of the heavily-

STREAMLINE. The design of the tail constitutes the most important feature of the streamlining. Note how the coach tapers almost to a point as in racing cars and aircraft.

After leaving Chicago, where 40 minutes were spent, the speed of the streamlined express was limited to that of the steam-

It is estimated that operating costs are from forty to fifty per cent less than for ordinary steam expresses.

The steady development of light-

In Britain also the use of rail cars has proved their worth, particularly on branch lines where fast and frequent services can be maintained at reduced cost. Pictures of the Great Western Railway’s streamlined car, of the Flying Hamburger and the French Bugatti Express are shown on this page, and details of these will be found in later chapters.

You can read more on

“British Diesel Rail Coaches”,

“The Rail-

“The Flying Hamburger” on this website.