© Railway Wonders of the World 2012-

| Advertisements |

| Articles by Cecil J Allen |

| Binding |

| Cookie Policy |

| Covers |

| Donate |

| FAQs |

| Illustrations |

| More on Railway Wonders |

| Other Series |

| Privacy & Terms of Use |

| List of Illustrations |

| Locomotive Illustrations |

| Carriage Illustrations |

| Wagon Illustrations |

| Part 1 |

| Part 2 |

| Part 3 |

| Part 4 |

| Part 5 |

| Part 6 |

| Part 7 |

| Part 8 |

| Part 9 |

| Part 10 |

| Part 11 |

| Part 12 |

| Part 13 |

| Part 14 |

| Part 15 |

| Part 16 |

| Part 17 |

| Part 18 |

| Part 19 |

| Part 20 |

| Part 21 |

| Part 22 |

| Part 23 |

| Part 24 |

| Editorial - Part 1 |

| Editorial - Part 2 |

| Editorial - Part 3 |

| Editorial - Part 4 |

| Editorial - Part 5 |

| Editorial - Part 6 |

| Editorial - Part 7 |

| Editorial - Part 8 |

| Editorial - Part 9 |

| Editorial - Part 10 |

| Editorial - Part 11 |

| Editorial - Part 12 |

| Editorial - Part 13 |

| Editorial - Part 14 |

| Editorial - Part 15 |

| Editorial - Part 16 |

| Editorial - Part 17 |

| Editorial - Part 18 |

| Editorial - Part 19 |

| Editorial - Part 20 |

| Editorial - Part 21 |

| Editorial - Part 22 |

| Editorial - Part 23 |

| Editorial - Part 24 |

| Part 25 |

| Part 26 |

| Part 27 |

| Part 28 |

| Part 29 |

| Part 30 |

| Part 31 |

| Part 32 |

| Part 33 |

| Part 34 |

| Part 35 |

| Part 36 |

| Part 37 |

| Part 38 |

| Part 39 |

| Part 40 |

| Part 41 |

| Part 42 |

| Part 43 |

| Part 44 |

| Part 45 |

| Part 46 |

| Part 47 |

| Part 48 |

| Part 49 |

| Part 50 |

Tunnelling Against Time

The Wonderful Story of America’s Eight-

LARGE ELECTRIC LOCOMOTIVES, such as those shown above, now haul the huge freight trains through the mountains. Note the great length of this train, which stretches into the far distance in a setting typical of the Cascade country.

ONE of the most amazing engineering feats of recent years was carried out on the system of the Great Northern Railway of America when a new tunnel was driven through the giant Cascade range from Scenic to Berne. Just on eight miles were completed within three years. This work was hustled through at such speed that tunnel constructions of the past seemed to be only small achievements, and all records for tunnelling were broken.

The object of the tunnel was to afford Seattle, on the Pacific Coast, more direct and easier communication with the cities in West and Central America. By the building of the Cascade Tunnel the railway company secured absolute protection from the peril of avalanches and eliminated the cost of maintaining snow-

In 1925 parties of engineers set out to survey the site. Owing to the length of the tunnel it was imperative that the work should proceed from more than two sides, and the surveyors decided that a shaft should be sunk in Mill Creek valley above the line of the tunnel Other problems of preliminary investigation were the location of the tunnel’s axis, the estimation of the difference in elevation between the east portal and the west portal, and the depth of the Mill Creek shaft.

The surveys were carried out in the heart of winter over a bleak and mountainous district, but, despite blizzards and snowstorms, the calculations proved to be extremely accurate.

Two weeks after the undertaking had been approved and handed over to the contractors, tunnelling began at a camp on the western side of the Cascades. And it was not long before three modern construction camps had been erected, two at either end and one in the middle at Mill Creek where the sinking of the shaft to the proposed level of the tunnel had begun. Most of the vast amount of the tunnel-

Two weeks after the undertaking had been approved and handed over to the contractors, tunnelling began at a camp on the western side of the Cascades. And it was not long before three modern construction camps had been erected, two at either end and one in the middle at Mill Creek where the sinking of the shaft to the proposed level of the tunnel had begun. Most of the vast amount of the tunnel-

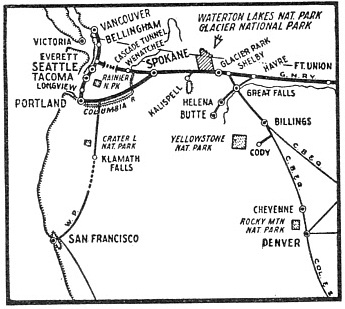

A VITAL LINK between the Pacific ports and the Eastern States is provided by the Cascade Tunnel, the situation of which is indicated here.

The difficulties that confronted the engineers were the seemingly impossible time limit imposed -

The time restrictions, in addition to the length of the tunnel, also made it necessary to begin work at several different places simultaneously, for it was quite clear that only a relatively small number of men and machines could concentrate at the east and west entrances. The construction of the Mill Creek shaft, two and half miles from the east portal, afforded two additional working faces.

When in August, 1926, Mill Creek shaft was completed, great skips were erected at the mouth to haul up the spoil from the excavations. Pumps were also installed in readiness to deal with any water that might be encountered. Light contractors’ engines for hauling rock, power shovels, drills and mechanical excavators (which were to assist both in the building of the main and the pioneer tunnels) were lowered down into the earth.

The pioneer tunnel, 8 ft by 9 ft, was begun in two places at once, eastwards from the entrance at Berne, and also at Mill Creek shaft. Work on these two sections of the pioneer tunnel, which met over two years later, proceeded in conjunction with work on the main tunnel through which one day the railway would run. As the dimensions of the pioneer tunnel were considerably less than those of the main one, it was always well in advance of the headings of the major operation. Cross-

Other important problems were also solved by this pioneer tunnel method. The small tunnel was used to drain away water from the large one. Through it ran the light trains, carrying labourers and supplies, and the rock hewn from the faces reached by the cross-

What occurred at one pioneer head is typical of the activity at the remainder. The work of the drills was divided into so-

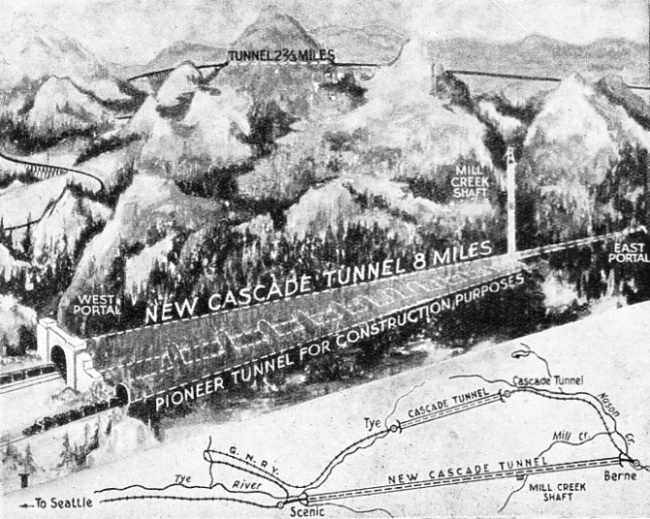

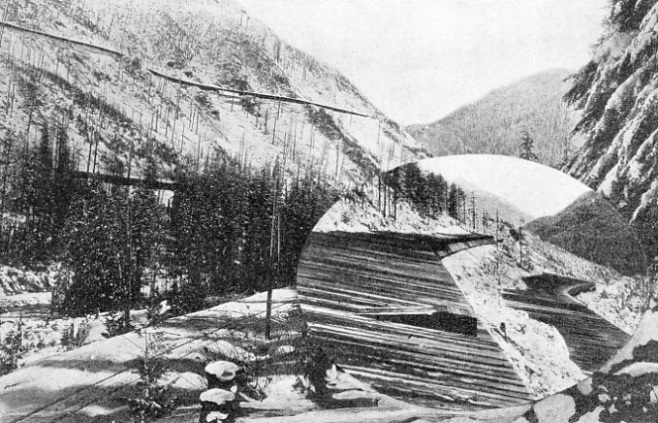

THE PROBLEM confronting the Cascade engineers was to save the detour through the original tunnel shown at the top of this picture. Their solution was to drive a new eight-

In a typical round, after 195 pounds of explosive had been fired, 6,000 cubic feet of air were directed at the shattered wall of rock to remove the noxious gases. Subsequently a shift of sixteen men brought forward the excavator, cleaned up the debris and replaced the power and compressed air lines, this procedure taking 38 minutes. For the next hour and a half the excavator poured the loosened spoil into wagons, each capable of holding 50 cubic feet, and filled them at the rate of one wagon in every three minutes. After the rock brought down had been removed, the drill carriage, on which were mounted four drills, was brought forward. While the drilling proceeded, a heavily insulated powder wagon was brought along containing the required quantity of explosive and detonators. Some of the drillers next ran back the drill carriage while the rest packed the holes with dynamite. When the charges had been set and the leads of the electric blasting caps had been connected up and tested, the men retreated from the face. The last man to leave -

A rigid time-

rigid time-

The complete success of this scientific method of dealing with so great a task is demonstrated by the fact that when the boring of the main tunnel was finished, over six miles of the track had been lined with concrete, while another mile had been widened to its final size and five miles of electric cable had been laid.

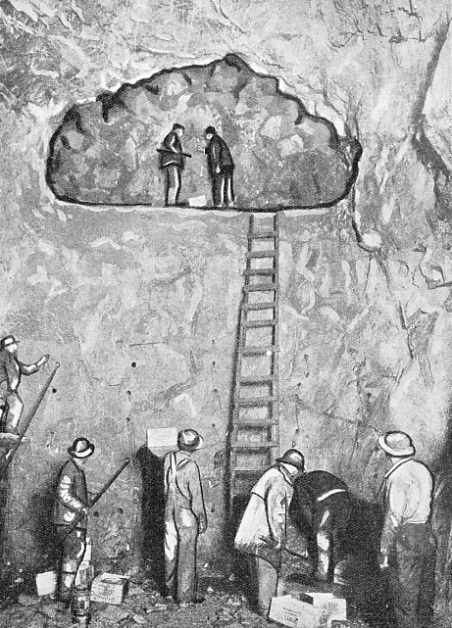

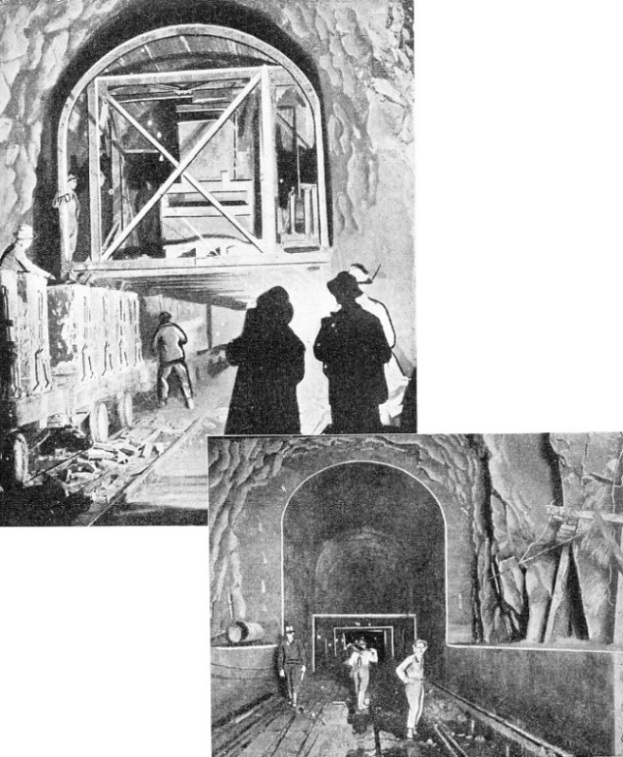

A PERILOUS TASK. Attacking the rock face by means of a pilot-

The amazing speed with which this work was done created a world’s record in tunnel construction. This was made possible by the concentration of the latest machinery in conjunction with electricity, dynamite and compressed air, and by the skilled workmen especially selected for the work. Drilling, blasting and excavating were carried out almost continuously; and there was but little opportunity even for such vital engineering tasks as testing the gradient and checking the levels.

Lining the walls of the tunnel with concrete represented one of the most skilful engineering feats. Within eighteen months the long bore of the tunnel was walled with 2 ft of concrete without any interference with the actual excavation work. As the distances from the tunnel mouth increased with the progress of boring, it became necessary to have the mixing plant at the spot where the concrete had to be poured, and a specially mobile and compact plant was designed. At the tunnel mouth crushed gravel and sand were loaded in the correct quantities into the concrete trains, which then took on cement from a nearby cement store before running along the tunnel to the mixers.

Lining the Walls

Concrete for the tunnel walls was poured through chutes in the sides of temporary moulds or “shuttering”, close against the walls. When the concrete was set the moulds were removed. The arch of the tunnel was dealt with by pumping the concrete between the steel forms and the ceiling by means of a “pneumatic gun”. Three plants were capable of concreting 400 ft per week.

This non-

The firing of explosives was one of the chief factors which contributed to air-

The rock that was brought down by blasting was transferred into trucks which were brought close up to the loading machine, a crane behind the loader lifting up an empty truck each time a full truck passed away from the shovel, placing it on to the loading truck so that no time should be lost.

The rock that was brought down by blasting was transferred into trucks which were brought close up to the loading machine, a crane behind the loader lifting up an empty truck each time a full truck passed away from the shovel, placing it on to the loading truck so that no time should be lost.

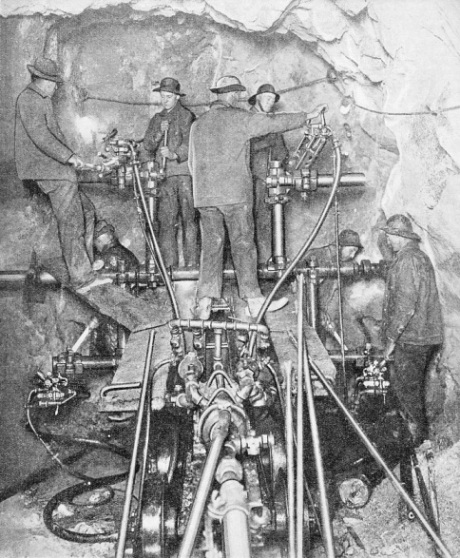

SOLID ROCK. A working face, showing a powerful drilling machine in action during the boring of the great Cascade Tunnel. Several drills such as those shown in the foreground were operated simultaneously by means of compressed air. The machine was run back on rails, and the drill holes were then loaded with explosives. After the rock had been blasted and cleared away the process was repeated, each operation representing a gain of approximately 8 ft. In constructing the tunnel 4,750,000 lb of explosives were used.

Automatic precision was the keynote of the whole enterprise, and the requisite speed without risk could be maintained only by a reliable source of power. Although the operations began with the aid of petrol-

Another problem, far greater than that of securing power, was presented by the danger of a sudden influx of water and the flooding of the tunnel. As a precaution a number of emergency pumps was erected at the Mill Creek shaft. For the first year, however, the builders experienced little difficulty in this direction, but in January, 1927, a burst of water from a drill hole flung a steel drill, 11 ft in length, some 50 ft away from the face. Four days later came an ominous rumbling sound, to be followed a second or so later by a roaring torrent of water which rushed out at the rate of 2,500 gallons a minute for several hours. From time to time similar occurrences impeded work, and just before May, 1928, when President Coolidge fired the last blast opening up the pioneer tunnel, the pumps were pouring out 2,200 gallons to the minute. Shortly after the pioneer tunnel had been cleared it became possible to use it for draining purposes, and the water problem was then less acute.

Another difficulty, although a lesser one, was the laying of the compressed-

CONCRETE LINED. The main tunnel was lined throughout with concrete, and this picture shows the type of framework used for this operation. The material was forced between the frames and the sides of the tunnel, and when the concrete had set the collapsible framework was removed.

ROCKY WALLS. This illustration gives an impression of the concrete lining after the removal of the framework shown in position in the upper picture. Embedded in the concrete are the pipes carrying electric cables for illumination. The clearance height of the roof above the top of the rails is 20 ft 10 in, and the width of the tunnel is 16 ft. As many as 1,793 men were employed at one time, and the co-

But precautions did not stop at the guarding of pipe-

To provide quarters for the small army of men, miniature towns sprang up at the east and west portals and at the Mill Creek shaft, from which roads were laid to the nearest railway. Unmarried men had their own quarters, while the married had three-

Feeding the Camp

The problem of supplying the mountain encampment with provisions and material: with clothing, drills, motors, pumps, boots, picks, shovels, machinery of every description: with milk, meat, bread and vegetables and medical requisites, was one demanding efficient organization. An office in the distant city of Seattle on the Pacific Coast handled the problem. In the winter, when the ways were blocked by heavy snowfalls, caterpillar-

On January 12, 1929, the Cascade Tunnel was finished and dedicated by the President of the Great Northern Railway, before the first electric train passed through. After thirty-

THE AVALANCHE MENACE which threatened the old route of the US Great Northern Railroad was formerly met by protecting the line with stout timbered snow-

You can read about “Engineering Equipment”, “The Great Apennine Tunnel”, “The Severn Tunnel” and “The Simplon Tunnel” on this website.