Hauling Long-Distance Trains at High Speeds

LOCOMOTIVES - 30

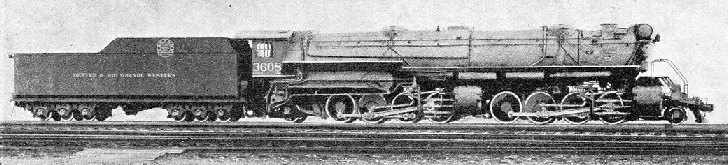

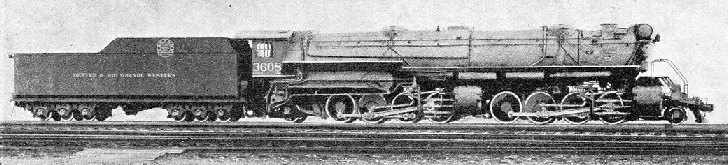

A “MALLET” 2-8-0+0-8-2 locomotive of the Denver and Rio Grande Western Railroad which has to negotiate heavy grades through the Rockies. The four cylinders are 26-in diameter by 32-in stroke; driving wheels have a diameter of 5 ft 3-in; heating surface totals 7,173 sq ft, and grate area 136½ sq ft. Working pressure is 240 lb per sq in, and tractive effort is 125,000 lb; without tender the engine weighs 262 tons, and with tender (including 27 tons of coal and 18,000 gallons of water) 435 tons. Engine and tender measure 118 ft in length overall.

AMERICANS are credited with a love of “big” things, and to this prevailing bigness their locomotives are no exception. Indeed, the majority of the largest and most powerful locomotives in the world have been designed to run on American metals. It is not merely for the sake of gratifying a desire for size that these giants of the rail have been built. There are many reasons why tractive power on so vast a scale has become necessary.

The most compelling of these reasons is the weight of American trains. In the earlier days of American railroading the operation of trains was often conducted in so reckless a manner, and accidents were so frequent, that a demand arose on the part of the American public for vehicles of more massive construction, better able to withstand the shock of collision. Gradually, therefore, there came into use all-steel coaches of progressively increasing weight. The modern American passenger coach or Pullman car, 70 or 75 ft in length and carried on two six-wheeled bogies, may, and indeed generally does, weigh from 75 to 85 tons. These are American “short” tons of two thousand pounds each, but even the British equivalent of 67 to 76 tons far outweighs the average 30 to 34 tons of an ordinary corridor coach, or the 40 to 45 tons of a dining or sleeping car on British railways.

When, therefore, a train of American stock has been assembled, the total weight behind the engine tender is more than double that of a British train made up of a corresponding number of vehicles. An American express of twelve coaches, with passengers and baggage, will scale about 850 English tons; but nowadays trains of fourteen, fifteen, or sixteen coaches, or even more, are common. The total weight to be hauled may thus rise to well over the 1,000 tons. For this reason alone it is not surprising to find in America passenger engines that are twice the weight, size, and tractive power of the biggest steam locomotives that have ever been built in Great Britain.

For the working of freight traffic, the principle of small consignments and short hauls which characterizes so much of freight working in Great Britain is replaced in America by large consignments and long hauls. This is one reason why the use of high-capacity wagons - often advocated by writers whose knowledge of the subject is no more than elementary - could not have the same economic advantage in Great Britain as on the North American Continent.

American conditions make it practicable to put together long trains of the large eight-wheeled “cars” which are standard in that country, and to run them over considerable distances with no stops other than those necessary for locomotive purposes. The day has come. when American freight trains of three thousand tons weight and upwards are being worked at average speeds of forty to forty-five miles an hour or so.

As for the slower freight, such as coal or minerals, on certain lines trains have been made up experimentally to as much as sixteen thousand tons weight, and have been hauled by one engine. The difficulty here has not been that of the haulage, but that of braking on falling gradients a train which may be a mile long. In American freight working, therefore, the need for exceptional tractive capacity is obvious.

But there are other features of American traffic operation that call for high tractive effort. Mention has been made in the chapter “Speed Trains of North America”, of the many factors which hamper continuous high-speed running in that country, such as level crossings of one railway over another, slow running through extensive freight yards, still slower running, in not a few places, through or across the streets in cities, and so on Thus, if a reasonably high average speed is to be maintained over long distances, with allowance for these hindrances, the locomotives must be sufficiently powerful to accelerate their enormous trains rapidly from the various slowings, and to maintain high speeds intermediately.

Lastly, there are the regions of America where heavy traffic has to be conducted through mountainous country, especially the vast area of the Allegheny Mountains and their outlying ranges in the Eastern States, and the far greater Rocky Mount-ains, which run down the whole length of the western seaboard. Many , of the largest locomotives in the world have been designed and built for service on main lines which cross the Rockies. But even the Alleghenies have a greater altitude than is generally realized. The main line of the Pennsylvania Railroad, from New York to Chicago, carrying one of the busiest train services in the United States, reaches at Gallitzin (Pa.), just to the west of Altoona, an altitude of 2,194 ft. This is approached by a lengthy ascent at 1 in 53 - almost half as steep again as the final four and a half miles to Shap Summit on the LMS main line in Westmorland.

Big American locomotives are, therefore, a necessity. In the development of this size, American railroads are greatly assisted by the fact that American railway pioneers looked farther ahead than did the British in deciding the space that should be left above and at the side of the tracks, to allow for the cross-sectional development of rolling stock. Thus the American locomotive designer can generally build up to a total height of 16 ft above rail level, as compared with the maximum of from 13 ft to 13 ft 6-in in Great Britain. The permissible width also is proportionately greater. Further, weights up to 30 tons, and even more, are imposed on one axle in American locomotives, compared with an absolute maximum of 221 tons in Great Britain. This difference also affects considerably the design of the locomotives.

The competition of other forms of transport, and particularly of Diesel propulsion, during recent years, no less than the unceasing public demand for more and more luxurious travel, has certainly directed the attention of American railway engineers to the excessive weight of their trains. The tour across America and Canada of the British “ Royal Scot” train in 1933 was an object lesson in what can be done in building lighter stock. Some of the latest American passenger coaches, therefore, in the construction of which welding, alloy steels, and aluminium have been used, weigh considerably less than their predecessors. The problem of weight is being seriously faced, in freight as well as in passenger operation. But as the weight reduction is being used chiefly to permit the acceleration of the services to much higher speeds, there is little likelihood of much diminution in the size or power of future American locomotive designs. There are certain essential points in which American locomotives in general differ from those of Great Britain. One of the most important is the design of the main frames. In Britain the main frames of the locomotives consist of two lengths of steel plate, about 1¼-in thick, slotted and machined out of the solid, set up on edge, and strongly braced together, and running the whole length of the engine from the buffer-beam to the cab. But in America these plate frames are replaced by bar frames, consisting of a lattice-work of steel bars which serve the same purpose.

Ample Loading Gauge

In many of the latest locomotives these bar frames are not assembled from steel sections, but are made as one steel casting from end to end. In some designs, indeed, not only the frames, but also the cylinders and valve-chests are cast in one casting of extraordinary complexity.

The increased space available on either side of the engine, due to the more liberal American loading gauge, has considerably influenced cylinder arrangements. In Great Britain the maximum possible diameter of cylinders between the frames is 21½-in, as in the “Sir Sam Fay” class of inside-cylinder 4-6-0’s of the late Great Central Railway. Outside the frames the maximum possible is 22-in, as in the big “Baltic” (4-6-4) type tank locomotives of the late London, Brighton and South Coast Railway “Stephenson” class, recently converted to tender engines of the 4-6-0 type. But in America it is possible to mount cylinders of as large a diameter as 30-in, and even more outside the frames, though from 26 to 28-in is the more common figure, with a stroke of 30 or, more generally, 32-in. The use, therefore, of three or four cylinders in place of two has never become popular on American railroads, and two-cylinder locomotives are now the almost universal rule, except in “Mallet” articulated designs.

The ample American loading gauge allows designers in that country to mount boilers of immense size on their engines, and in general the proportion of heating surface and firegrate area to the volume of the cylinders is greater than in Great Britain. This is partly because the quality of American fuel is not the equal, in its calorific value, of that used in Great Britain, and greater space must be provided on the grate to allow of efficient combustion. In the bigger engines firegrates having an area of from 85 to well over 100 sq ft are common, as compared, say, with the 45 sq ft of a LNER “Pacific”. In such conditions it would be impossible, of course, for a fireman to keep the fire supplied by ordinary manual means, and mechanical stoking is therefore customary. The coal, which is broken small for the purpose, is brought forward from the tender on to the firegrate by means of a feed screw arrangement. The speed of rotation of this device regulates the amount of coal that is fired.

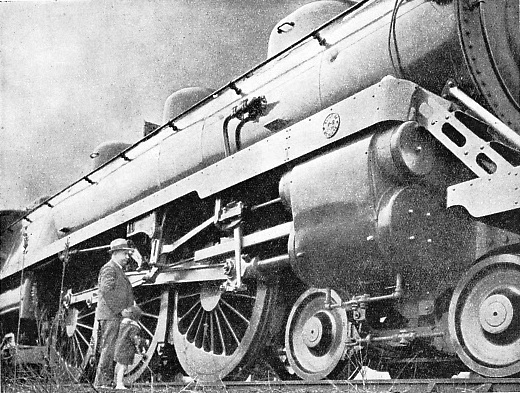

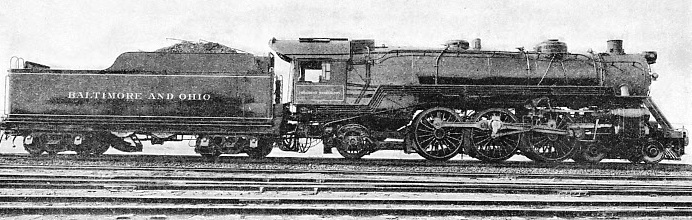

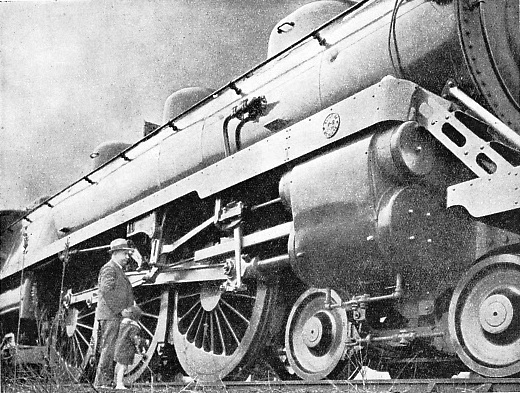

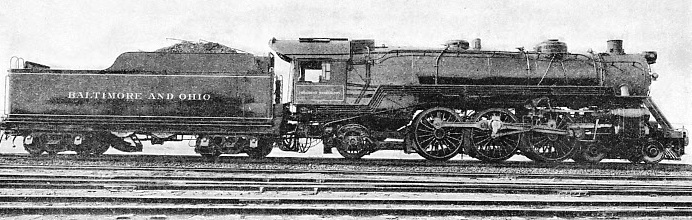

A SMOOTH STREAMLINED EXTERIOR is a feature of Baltimore and Ohio Railroad for working its new fast services, such as the “Abraham Lincoln”. This is the new 4-6-4 type. Note the disk bogie wheels, which are provided with brake power.

The first of these wide fireboxes, spreading right across the frames, that were fitted on American locomotives were known as Wootten fireboxes. In not a few of the earlier engines so equipped it was thought that the size of the firebox might interfere with the look-out ahead, and the driver’s cab was therefore perched astride the boiler, ahead of the firebox, while the fireman had a cab to himself at the rear end, in the usual position. The Philadelphia and Reading Railroad, or “Reading” for short, had a considerable fondness for this type, and, as mentioned in the chapter on “Speed Trains of North America”, used “Atlantic” engines with mid-boiler cabs and Wootten fireboxes largely on its fast express services between Camden (Pa.) and Atlantic City. A modification of the Wootten firebox was first seen in England on the Ivatt “Atlantics” of the late Great Northern Railway. The design has now spread to the LNER and LMS “Pacifics”. But the size of these modern American fireboxes is so great that a single axle is no longer adequate to carry them, and on many modern designs it has been replaced by a bogie at the rear end. The “Pacifics” have therefore developed into 4-6-4’s (nicknamed “Hudson” after the New York Central 4-6-4’s), and the “Mountains” into 4-8-4 locomotives. Where “boosters” are employed, they are usually fitted to one of the axles of the bogie carrying the firebox. Another wheel arrangement becoming increasingly common for heavy freight service is the 2-10-4.

Some tests conducted recently with a typical modern 2-10-4 locomotive - No. 3000 of the Chesapeake and Ohio Railroad, one of forty built in 1930 - illustrate admirably the power of these modern American creations. The engine in question has 5 ft 9-in driving wheels, two cylinders 29-in diameter by 34-in stroke, a working pressure of 260 lb per sq in, an evaporative heating surface of 6,635, and a superheating surface of 3,030 sq ft. The firegrate is 13 ft 6-in long and 9 ft wide, with an area of 121.7 sq ft. The engine’s weight in working order, without tender, is 252¼ tons, of which 166½ tons - 33.3 tons per axle - rest on the driving wheels. The tractive effort is 91,585 lb, or, with the addition of the booster, 106,585 lb. This tractive effort, even without booster, is more than twice that exerted by “The Princess Royal”, the well-known “Pacific” of the LMS Railway.

The test trains each consisted of 141 freight cars, all eight-wheelers, weighing in all 10,939 American tons, or 9,770 British tons behind the engine tender - at least eight times the weight of an eighty-wagons freight train in Great Britain. They run over a stretch of line 236 miles long between Russell (Kentucky), and Toledo (Ohio). The steepest grade on the route against the engines of loaded trains is one of 1 in 140, up which the previous 2-8-4 locomotives and 2-8-0+0-8-2 “Mallets” required banking assistance with similar loads. The 2-10-4 climbed the bank unassisted. The overall journey times averaged 13 hours 17 minutes, but, after deduction of stops, the time was 10 hours 42 minutes, and the average speed, with this 9,770-tons load, was 22.1 miles an hour.

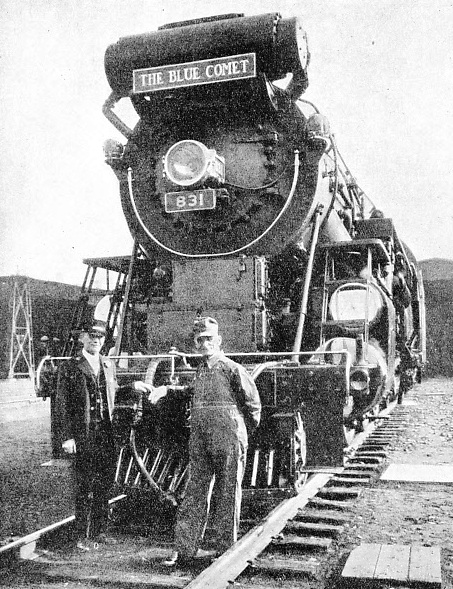

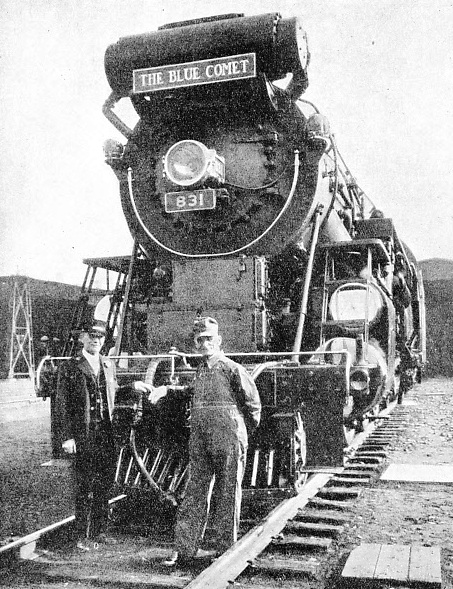

THE ENGINES OF CRACK EXPRESSES are now painted to harmonize with the coaches of their trains, and this powerful “Pacific” of the Central Railroad of New Jersey, used on the “Blue Comet” express from New York to Atlantic City, is further embellished with electro-plated heads to the cylinders and valve chests. Engine No. 831 has 6 ft 7-in driving wheels, a working pressure of 230 lb per sq in, and a tractive effort of 46,920 lb. It weighs, with tender, 241 tons in running trim. Note the feed-water heater, arranged transversely in front of the chimney.

A total of 75,900 lb of coal was fired on each trip, which works out at 8,686 lb an hour, or 71.4 lb on every square foot of the firegrate every hour; and a total of 62,219 US gallons of water was evaporated. Throughout the journey the average pull on the train was 43,921 lb (nearly 20 tons), and the horse-power exerted at the drawbar averaged 2,625. For every horse-power developed per hour at the drawbar an average of 3.37 lb of coal was fired, which is a moderate figure in freight service, especially with the comparatively low calorific value of American fuel. Such figures as these show that these modern American giants are capable of work on the road which is fully in proportion to their dimensions. Numerous modern American designs are sufficiently powerful to develop a maximum of 4,000 to 5,000 horse-power in the cylinders, and 3,000 to 4,000 horsepower at the drawbar.

To feed such huge engines as these, tenders of colossal size and capacity are needed. Most modern American locomotives are equipped with twelve-wheeled tenders, with bogies spaced so far apart that the tender is often almost equal in length to a coach. Some of the latest Pennsylvania tenders are even longer than the locomotives to which they are attached, and accommodate 22,090 gallons of water and 31½ tons of coal. This compares, say, with the eight-wheeled tender of one of the LNER “Pacifics”, which holds 5,000 gallons of water and 9 tons of coal. In full running trim these Pennsylvania tenders weigh 168 tons, which alone is more than the LNER 4-6-2 and its tender put together.

Such high capacities as these make it possible for these powerful locomotives to run for considerable distances without replenishment of their supplies, although they add materially to the weight that the locomotives have to haul. In design, American tenders vary considerably, from the ordinary flat-sided type to the Vanderbilt type of tender, with its water-tank of cylindrical shape, and the coal carried in a large hopper above the tank at the front end. The proportion of tender weight to locomotive weight in modern American locomotives varies from 45 per cent in express passenger engines to 36 per cent in the heaviest “Mallet” freight engines.

Prominent American Features

In external appearance there are many ways in which American locomotives differ from British. In addition to the steam dome, on the top of the boiler, a dome of larger size and somewhat misshapen appearance houses the sand-box. This position astride the boiler is favoured for the sand-box, as the warmth of the boiler keeps the sand in a dry condition. The driving wheels of American engines are always fully exposed to view, instead of their upper parts being covered with splashers, as is usual in Great Britain.

Well above the wheels, in a straight line from one end of the engine to the other, is the running-plate, with steps down to the buffer-beam at the front end, and a door admitting to the cab at the rear end. In one or two of the modern designs, however, the fireboxes are of such a width that this cab entry is impossible. Below the running-plate may be seen the compressed-air brake reservoir cylinders, and various other details. Feed-water heaters are often now placed across the top of the smoke-box, ahead of the chimney.

A feature that has persisted from the earliest days is the assemblage of steel bars mounted in front of the buffer-beam, called the “cow-catcher”. As its name implies, this was first introduced because of the risk of cattle straying on to the unfenced tracks. This attachment is still standard. For the same reason, a powerful head-lamp is carried by all American locomotives, to give the driver the opportunity of seeing in good time any obstructions ahead. Most modern American locomotives carry their own small steam-driven turboelectric plant, thus generating their current as they run, not only for the head-lamp, but also for lighting up the cab, the valve motion, and so on.

During recent years there has been a tendency to “clean up” the external lines of American engines. There is little doubt that the visit of the Great Western Railway 4-6-0 engine “King George V” to the “Fair of the Iron Horse”, at Baltimore, in 1927, and of the LMS “Royal Scot” to the World’s Fair at Chicago, had some influence in this direction. But it has also been realized that the removal of all unnecessary excrescences from the engine outline helps towards a streamlining effect, which in its turn reduces air resistance at high speeds and increases the efficiency of the engine. Great improvements have been effected in this respect in the externals of recent American designs.

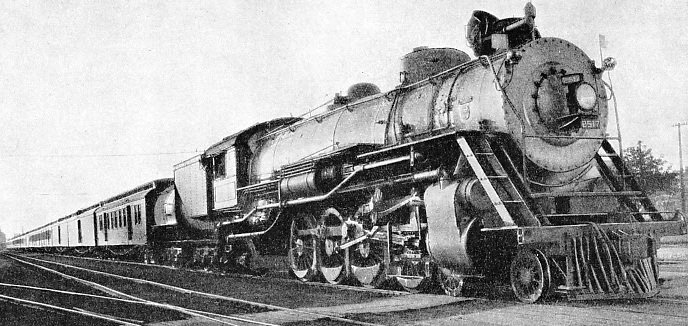

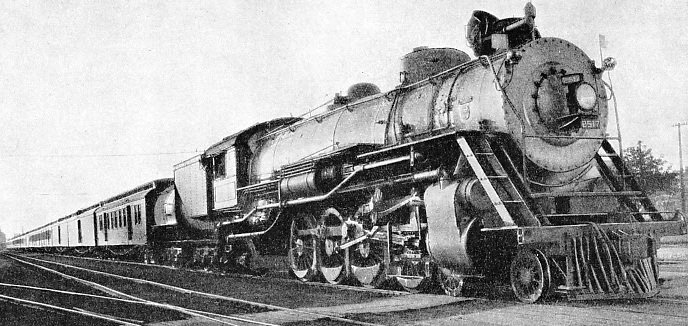

FOR 1,765 MILES CONTINUOUSLY 4-8-2 Engine No. 2517 hauled this “Silk Special” over the main line of the Great Northern Railroad from Seattle to St. Paul, in fifty hours - probably a world’s record for one locomotive. The value of the fourteen carloads of silk was approximately £1,000,000, and fast running was essential, as were also a clear road and an armed guard for this valuable freight.

But in the special designs that have been evolved for ultra-high-speed work this principle has been carried considerably farther. Of these perhaps the most striking example is the new design of engine evolved by the Chicago, Milwaukee, St. Paul and Pacific Railroad for hauling the streamlined “Hiawatha” express between Chicago, Milwaukee, St. Paul, and Minneapolis. In this type of engine there is a reversion to four-coupled driving wheels and to the “Atlantic” wheel arrangement.

To assist in maintaining high speeds, the driving wheels are increased in size from the general American average of 6 ft or 6 ft 3-in to 7 ft, but the cylinders are of moderate size, 19-in diameter by 28-in stroke. Heating surface totals 3,245 sq ft, and superheating surface 1,029 sq ft, while the firegrate has an area of 69 sq ft. Oil is used for fuel, however, instead of coal. The working pressure is 300 lb per sq. inch. Each pair of coupled wheels carries 31¼ tons of the weight of the engine; adhesion weight therefore totals 62½ tons, which is exactly one-half the 125-tons weight of the engine.

The tender, with 4,000 gallons of fuel oil and 13,000 gallons of water, weighs 110½ tons in running trim, the joint weight of engine and tender being thus 235½ tons. The tender itself has a curious wheel arrangement, with a six-wheeled bogie at the leading end and a four-wheeled bogie at the rear end.

A Streamlined Train

But the most striking feature of the engine is the streamlined sheathing, extending upwards from the track to the chimney, which is completely hidden at the leading end, and then down the full length of the engine and tender from front to rear. The casing is raised from the cylinders onwards sufficiently high to clear the motion and the lower part of the wheels, so making these details accessible. To attract attention, the streamlined casing is beautifully finished off in gamboge colour, similar in shade to that which was once worn by the locomotives of the English London, Brighton and South Coast Railway. The design of the coaches, which have been reduced in weight from the general standard of 75 to 85 American tons to 50 tons apiece, has also been carefully studied for weight-reducing purposes. These also are streamlined. They are equipped with “Timken” roller bearings, which are more and more coming into use in America, with a view to reducing the rolling resistance of coaches, tenders, and even locomotives. A similar complete streamlined casing has been applied for experimental purposes to one of the large “Hudson” (4-6-4) type express locomotives of the New York Central Lines, which is illustrated on page 1045 at the head of an express train. It seems likely that there will be considerable future developments of this principle in the United States.

For working the high-speed services between New York and Washington, and between St. Louis and Chicago, the Baltimore and Ohio Railroad has introduced some new 4-4-4 express engines of a rather more orthodox type. The “Lady Baltimore” has 7 ft driving wheels, Cylinders 17½-in diameter by 28-in stroke, a heating surface of 1,780 sq ft, a superheating surface of 351 sq ft, and a firegrate area of 61¾ sq ft. The working pressure is extremely high, being fixed at 350 lb per sq in, and this helps to explain the comparatively small diameter of the cylinders.

In working order this locomotive, which carries 44½ tons on its coupled wheels, weighs 95½ tons, which is no more than one of the LNER “Pacifics”. With the tender, which accommodates 14 tons of coal, and 8,000 gallons of water, it weighs 165 tons. In this considerable reduction of traditional American locomotive weight the use of alloy steels has played a considerable part. The “Lady Baltimore” has been painted blue, to harmonize with the new streamlined aluminium stock which it has been designed to haul.

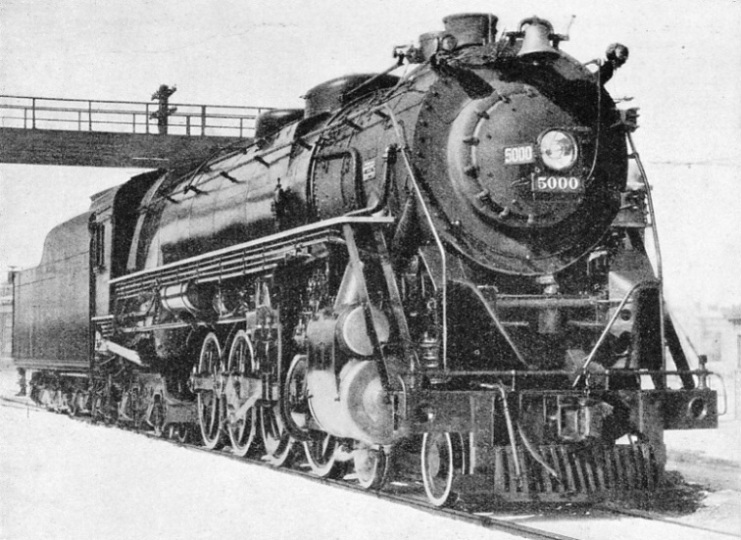

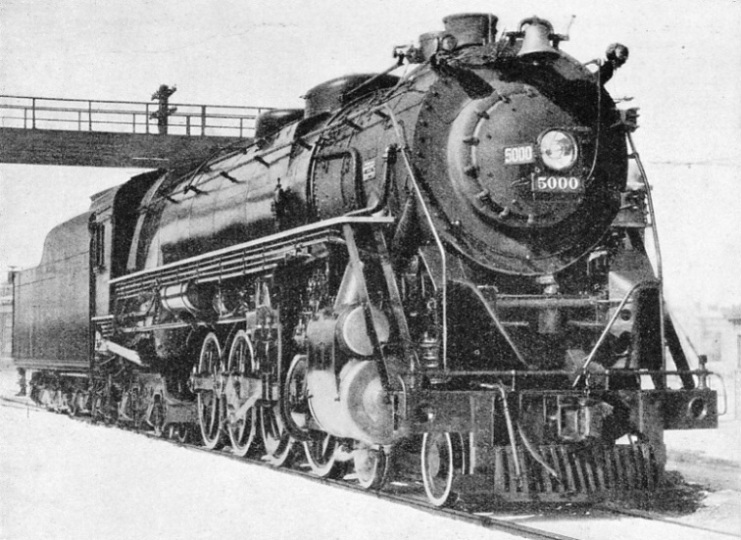

A HEAD-ON VIEW of freight locomotive No. 5000 of the Rock Island Lines shows features of equipment which are standard in North America, such as the cow-catcher, electric headlight, and “marker” lights on either side of the chimney, with the bell between. The engine is of the 4-8-4 type, with 5 ft 9-in driving wheels, and a tractive effort of 66,620 lb, increased with booster to 79,700 lb. The engine weighs 194 tons, or, with tender, 327 tons. The tender capacity is 15,000 gallons of water and 20 tons of coal.

A similar 4-6-4 high-speed Baltimore and Ohio locomotive, also with 7 ft drivers and 350 lb pressure, has rather more ample dimensions - 19 by 28-in cylinders, 3,339 sq ft of heating surface and 720 sq ft of superheating surface, and 61¾ sq ft of firegrate. In this example the tender carries 10,000 gallons of water and 16 tons of coal; the engine alone weighs 131¼ tons, and engine and tender together 220½ tons. Both locomotives are provided with booster assistance, the light-weight booster engine driving one of the axles of the bogie truck which carries the firebox. The 4-4-4 has a tractive effort of 28,000 lb and the 4-6-4 one of 35,000 lb, the booster adding 7,000 lb to this figure in either instance.

The mention of oil fuel in connexion with the streamlined “Hiawatha” 4-4-2 design of the Chicago, Milwaukee, St. Paul and Pacific Railroad is a reminder that oil fuel is used extensively for locomotive firing on the Pacific coast. It is a question of simple economics. Where the oil is indigenous and the coal has to be hauled over long distances, it is cheaper to fire with oil; but, where the opposite conditions prevail, coal is the cheaper fuel, though it may be replaced with oil where special conditions, such as the high speed of the services round Chicago, make this desirable. The Southern Pacific Railroad, therefore, has many locomotives equipped for oil-firing, as extensive supplies of suitable oil are obtained from the many wells on the Californian coast.

An Unusual Design

Of these engines perhaps the most interesting are the enormous articulated examples of the 4-8-0+0-8-4 type, used both for passenger and freight service, in which the whole locomotive has, in effect, been turned round. It carries the cab and firebox at the leading end, and the chimney at the rear end, with the tender behind that. There is no difficulty in making this arrangement with oil firing, of course, as there is no coal to transfer from the tender to the firebox, and the oil can be conveyed by piping from the tender to the front end of the engine just as easily as to the rear. To the engine crew, of course, this reversal of the engine is a great advantage, as the look-out ahead is ideal, and the exhaust from the chimney is kept entirely clear of the cab. A railway in the north of Italy once built some 4-6-0 locomotives on somewhat similar lines; these were coal-fired engines, however, and the coal was stored in a bunker which formed a part of the cab roof. There are, at the time of writing, twenty-five of these Southern Pacific giants, each one with four cylinders 24-in diameter by 32-in stroke.

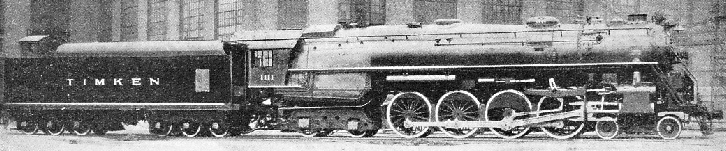

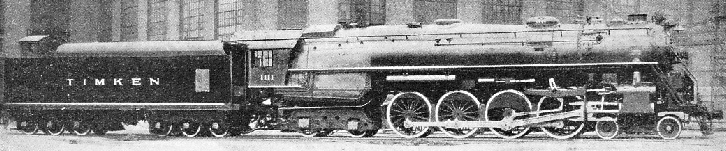

BUILT FOR PUBLICITY, this giant 4-8-4 locomotive was constructed to the order of the Timken Co, to demonstrate the practicability of roller bearings for all engines and tender wheels, driving wheels included. The engine has since been purchased by the Northern Pacific Railroad for service through the Rockies. It has 27-in by 30-in cylinders, 6 ft 1-in driving wheels, 250 lb pressure, and a total heating surface of 7,277 sq ft.

But they are easily exceeded in size by some vast machines built in 1930 by the Baldwin Locomotive Works for service on the Northern Pacific Railroad through the heavy gradients of the Rockies. Their wheel arrangement is 2-8-0+0-8-4, and the boilers, with 7,666 sq ft of evaporative heating surface and 3,224 sq ft of super heating surface - 10,890 sq ft in all - are, at the moment of writing, the largest ever mounted on a locomotive chassis. The firebox is no less than 22¼ ft long and 9½ ft wide, with a grate having the prodigious area of 182 sq ft; equal, indeed, to the floor space of a fair-sized room. Four cylinders, 26-in diameter by 32-in stroke, together with 5 ft 3-in driving wheels and a working pressure of 250 lb per sq in, combine to give a maximum tractive effort of 139,900 lb. This can be increased to 153,000 lb by cutting in the booster. For one of the LMS “Pacifics” or a Great Western “King” the corresponding figure is 40,300 lb. To provide the firebox with sufficient fuel a mechanical stoker is provided which is capable of delivering it on to the firegrate at a maximum rate of 40,000 lb - 18 tons - per hour. At this rate the coal space of the tender of a LNER “Pacific” would be cleaned out at half-hourly intervals.

“PRESIDENT WASHINGTON”, a Pacific type locomotive, named after the first President of the United States, is one of a series of twenty-one express locomotives built for the Baltimore and Ohio Railroad by the Baldwin Locomotive Works, for high-speed passenger traffic between Washington and New York. These locomotives mark a departure from the standard black by a new colour scheme of olive green with stripes of gold and maroon. Each is named after a President of the United States. They are equipped with all modern appliances, and have 6 ft 8-in diameter driving wheels, and train-control device.

The barrel of the boiler tapers from an inside diameter of 8 ft 7¼-in at the front end to 9 ft 2¼-in at the rear end. The complete length of smoke-box, barrel, and firebox is 63 ft 9-in, and the estimated weight of all three, without water, is 73 tons. To supply the boiler with water two centrifugal pumps are fitted. They are able, if required, to deliver water at the rate of 120,000 lb per hour, which should suffice to slake the most colossal thirst on record. The tenders run, as usual, on twelve wheels, and carry 21,200 gallons of water and 27 tons of coal. One reason for the enormous dimensions of these extraordinary machines is that the coal immediately available is of a poor quality, with a moisture content as high as 30 per cent. The 14 per cent of ash helps to explain the size of the firebox. As to weight, the engine turns the scale at 322 tons, and the tender at 179½ tons, making up the unprecedented total of 501½ tons. Engine and tender together measure exactly 125 ft in length.

World’s Largest Locomotives

Twelve of these locomotives have been placed in service, and they have been built to work 4,000-tons trains over a route which has lengthy adverse grades at 1 in 90. At the time of writing they are probably the largest and most powerful steam locomotives in the world.

One feature of locomotive running on the North American continent creates records which have no parallel in any other part of the world. It is the enormous distances that are run continuously by steam locomotives without change. For example, on the Canadian Pacific Railway it is customary to run one locomotive unchanged on the important transcontinental trains between Winnipeg and Calgary, a distance of 836 miles. The journey occupies all but twenty-four hours, and changes of crew take place at various divisional points, but the engine continues hard at work without respite. The vast fireboxes of modern American locomotives are of considerable help in this direction, and a standard detail of equipment is the mechanical appliance for shaking up the grate when required, and so preventing the formation of clinker.

The Chicago, Milwaukee, St. Paul and Pacific Railroad has an even longer turn of locomotive duty, through from Minneapolis to Harlowton, Montana, a distance of 914 miles. The Baltimore and Ohio Railroad has unchanged locomotive runs over the 786 miles from Washington to Chicago. But all these records are broken by the Southern Pacific Railroad, which succeeds in running its principal trains from Los Angeles, on the Pacific coast, right through to New Orleans with only one change of locomotive, at El Paso (Texas). The Los Angeles to El Paso stage is 815 miles, and the El Paso to New Orleans stage no less than 1,193 miles in length, the two together thus totalling 2,008 miles. The advantage of such methods, of course, is that of reducing the idle time of engines between trips.

A SEVENTY-WAGONS FREIGHT TRAIN on the Southern Pacific Railroad being hauled by one of the large oil-fired 4-8-0+0-8-4 articulated engines of the “4100” class, which have the cab and the firebox at the leading end, and the chimney and the tender in the rear. There is no difficulty in making this arrangement with oil-fired engines. These locomotives, with four cylinders each measuring 24 by 32-in, are employed on either passenger or freight service. The look-out ahead is unimpeded.

Some important experiments designed to increase locomotive efficiency have been carried out over a series of years by the Delaware and Hudson Railroad, one of the underlying principles being the use of higher working pressures than before. The first experimental engine was built towards the end of 1924, and was named “Horatio Allen”. Its boiler is a kind of comb-ination of a water-tube boiler and a locomotive boiler of the ordinary type. The main boiler is of 5 ft 2-in diameter, and carries a working pressure of 350 lb per sq in. The firebox is of a water-tube type, with a steam and water drum of 2 ft 6-in diameter above, and two water drums at the two lower sides, connected to the upper drum by nests of water-tubes. These go up vertically on either side of the firegrate. The latter, with its area of 71½ sq ft, is designed to burn a mixture of bituminous and anthracite coal. With a superheating surface of 579 sq ft the total heating surface is 3,779 sq ft.

Compound propulsion is used, with one high-pressure cylinder 23½-in diameter by 30-in stroke, and one low-pressure cylinder 41-in diameter by 30-in stroke. The wheel arrangement of this 150-tons engine is 2-8-0, with 4 ft 9 in driving wheels, and the total weight of the engine is 150 tons. When working simple the tractive effort developed is 84,300 lb, and when working full compound 70,300 lb; this can be augmented by 19,700 lb when the booster, operating the wheels of the hind bogie of the tender, is cut in.

It cannot be said that “Horatio Allen” is a handsome machine, but, as has been emphasized previously, in locomotive work “handsome is as handsome does” is the most reliable maxim.

On test this remarkable locomotive, on a series of test runs with heavy freight trains over a line with a continuously rising gradient of 1 in 200, showed a coal consumption no greater than 2.31 lb per drawbar-horse-power per hour, or 2.19 lb per indicated horse-power per hour, both of which are extremely low figures. The overall thermal efficiency slightly exceeded eight per cent, which again was notable. After two years’ hard work by “Horatio Allen”, it was decided to build a further locomotive of a more advanced type, also with the 2-8-0 wheel arrangement. This engine appeared in 1927, and received the name “John B. Jervis”.

In the later engine the appearance was somewhat improved by casing the water-tube boiler over, from the smoke-box to the cab, and thus presenting a smooth exterior. The casing extends to the maximum height permitted by the loading gauge, and as in the design of “Cock o’ the North” on the LNER, no boiler mountings are visible above. By spacing the lower water drums more widely apart, the firegrate area was increased to 82 sq ft, and the boiler was modified in such a way as to permit an increase in the superheat temperature from 600 to 700 degrees Fahrenheit, while the working pressure was increased from 350 lb to the high figure of 400 lb per sq in.

Triple Expansion

The low-pressure cylinder was reduced in size and became 38-in diameter by 30-in stroke, and, by the use of cast steel for the cylinder block, and of other modifications, the weight of the new locomotive was reduced by 15 tons.

The superheating surface now became 700 sq ft, and brought the total heating surface up to 3,821 sq ft. Tractive effort remained 84,300 lb simple, or 70,300 lb compound, with 18,000 lb more available by the use of the booster. The weight of engine was 135 tons, or 284 tons with tender.

Next, in 1930, there came a third high-pressure 2-8-0, “James Archibald”, with still smaller cylinders - 20½-in by 32-in high-pressure and 35½-in by 32-in low-pressure - but the boiler pressure was raised yet further to the high figure of 500 lb per sq in. To raise steam at such a pressure required an increase in the evaporative heating surface to 3,439 sq ft, and in the super-heating surface to 1,037 sq ft - a total of 4,476 sq ft; but the water-tube principle was maintained. The strengthening of the boiler and steam passages to withstand this pressure occasioned a considerable increase in the engine weight, however, which consequently rose to 160 tons.

The fourth in this remarkable line of succession is “L.F. Loree”, which was turned out in 1932. A short reference to this locomotive, which is illustrated on pages 596-7 of this work, is made in the chapter “Articulated Locomotives”, beginning on page 978. It is believed that “L. F. Loree” is only the second attempt in locomotive history to utilize triple expansion since the unsuccessful experiment made by F. W. Webb on the London and North Western Railway in 1895.

The wheel arrangement is 4-8-0, and four cylinders are provided. Of these one is the high-pressure cylinder, 20-in diameter by 32-in stroke, located under the driver’s side of the cab; and the second is the intermediate-pressure cylinder, under the fireman’s side of the cab, 27-in diameter by 32-in stroke. Then, in the customary position below the smoke-box on either side, there are the two low-pressure cylinders, both 33-in diameter by 32-in stroke.

The eight coupled wheels are of 5 ft 3 in diameter, the combined evaporative and superheating surface 4,427 sq ft, the grate area is 76 sq ft, and the weight of the engine in working order 170½ tons. The tender, carrying fifteen and a half tons of coal and 11,700 gallons of water, has a two-cylinder booster which takes steam direct from the boiler at 500 lb per sq in, and functions until speed has reached ten miles per hour.

When starting “simple”, the engine can exert a tractive effort of about 90,000 lb, or 108,000 lb with the addition of the booster; when working triple expansion, after it has got its load well on the move, the tractive effort is in the neighbour-hood of 75,000 lb.

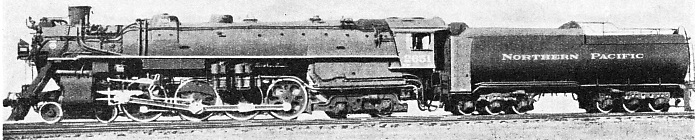

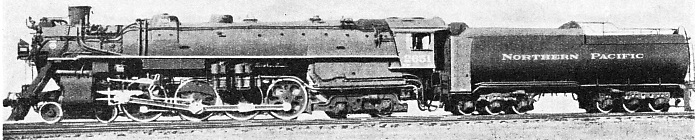

DISK DRIVING WHEELS, with holes for weight-reduction purposes, are a feature of some modern American locomotive designs. There are various other points of interest about this recent Northern Pacific 4-8-4 express passenger engine, which is equipped with disk wheels throughout, an enlarged chimney, and a Vanderbilt or barrel-shaped tender.

You can read more on “Locomotive Giants”, “Modern Locomotives”, “North American Railroads” and “Unconventional Locomotives” on this website.

You can read more on “Mammoths of American Railroads” in Wonders of World Engineering