Secrets of One of Britain’s Most Famous Locomotives

LOCOMOTIVES - 12

COMPETITION is always stimulating. There is no question that the competition of other forms of transport has stirred the locomotive engineers considerably. Diesel rail-cars, for example, have established a new mode of high speed transport on rails. Electrification, where traffic conditions are sufficiently dense to warrant the heavy expenditure involved, has been carried out on an extensive scale. Competition from outside the railways, on the roads, and in the air has to be fought unceasingly.

But “King Coal” is determined to hold his own. On a thermal efficiency basis the steam locomotive of traditional design does not rank very high. Even in the best conditions, not much more than seven per cent of the heat units developed by the burning of the coal on the locomotive fire-grate is turned into useful work in moving the locomotive and its train.

There are, as previously explained, many reasons to account for this figure. The use of the exhaust steam to furnish a draught for the fire necessarily means that power for the purpose must be thrown to waste out of the chimney, whereas in a stationary power-station the steam would be condensed, and its heat, at least, would be trapped. Similarly the limitations imposed in length and diameter on the locomotive boiler involve the loss up the chimney of much of the heat from the fire.

Some years ago the locomotive engineers of the Paris-Orleans Railway of France made an exhaustive study of all the features of locomotive design which have a bearing on efficiency. Their study concentrated on the “flow” of the steam from the time it left the boiler until the moment of its rejection, as exhaust, from the chimney. It was realized that much could be done by the use of larger and more direct steam-pipes and passages, and of improved inlet and exhaust valves to the cylinders, to facilitate that flow. Measures could also be taken to speed up the circulation of the water in the boiler, and this would increase the capacity to raise steam.

An existing “Pacific” locomotive was rebuilt in the Paris-Orleans workshops at Tours to embody the results of this research. The effect was startling. The reconditioned engine, though weighing no more than one of the London and North Eastern “Pacifics”, created new standards of combined speed and weight haulage on what was already a very speedy line. It was proved that trains weighing over 800 tons could be hauled not merely to scheduled time but well within it.

An existing “Pacific” locomotive was rebuilt in the Paris-Orleans workshops at Tours to embody the results of this research. The effect was startling. The reconditioned engine, though weighing no more than one of the London and North Eastern “Pacifics”, created new standards of combined speed and weight haulage on what was already a very speedy line. It was proved that trains weighing over 800 tons could be hauled not merely to scheduled time but well within it.

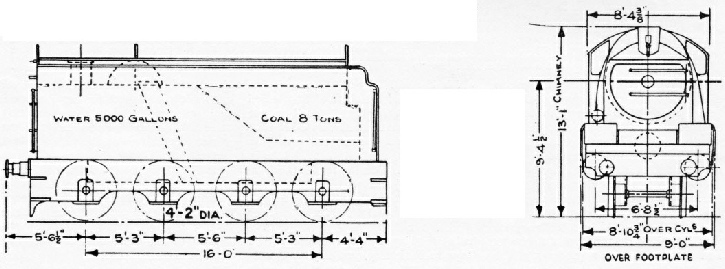

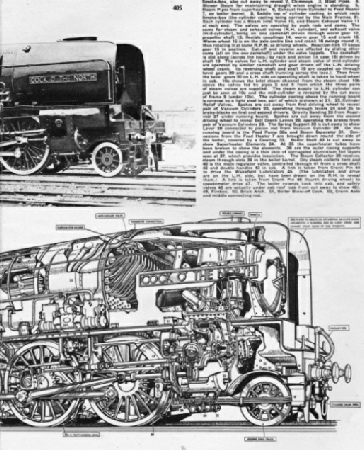

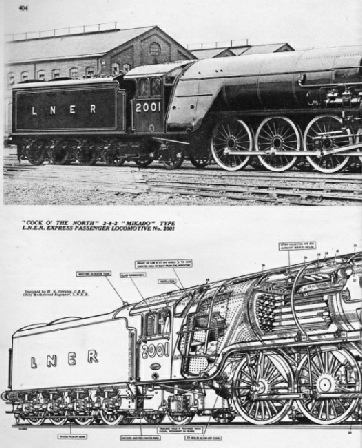

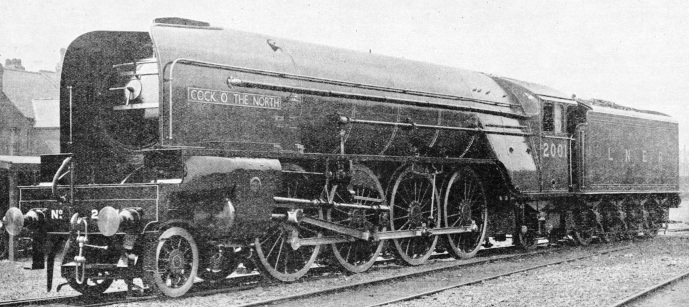

HERALD OF A NEW ORDER. The striking appearance of the great LNER locomotive is indicative of the revolutionary changes in design that she embodies. The “Cock o’ the North” was the first eight-coupled locomotive built for express passenger service in Great Britain.

A series of these earlier “Pacifics” was reconditioned, and the next experiment was to convert another “Pacific” to the 4-8-0 wheel arrangement, with a similar boiler, cylinders, and valves, for working over the extremely difficult route through Central France from Vierzon (to which point the trains are worked electrically from Paris) to Toulouse. Again the results were successful.

These developments attracted attention all over France. Other French railways followed suit, and as some of the Paris-Orleans steam locomotive stock was becoming superfluous, owing to the extension of main line electrification from Paris to Tours as well as Vierzon, the Paris-Orleans rebuilt many more of its “Pacifics” for transfer to the Nord and the Est Companies. The news of these Paris-Orleans transformations spread to England when the London and North Eastern Railway was about to build new locomotives for service over the heavily-graded east coast main line between Edinburgh and Aberdeen.

This is one of the most difficult main routes, from the locomotive point of view, in Great Britain. Gradients as steep as 1 in 70 abound. There are also numerous sharp curves demanding reductions of speed, most of them at the beginning of long adverse gradients so that the drivers are compelled to slow down severely just when they are in most need of the impetus for the climb that follows.

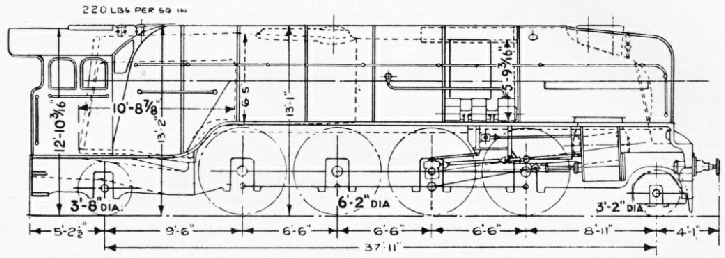

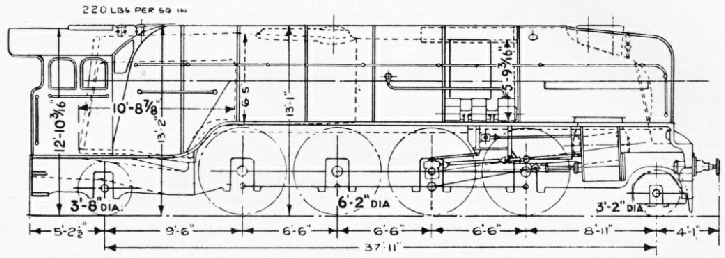

THE LEADING DIMENSIONS of this 110-ton locomotive, as given in these diagrams were supplied by the courtesy of the LNER Chief Mechanical Engineer’s Department.

From Inverkeithing, for example, after slowing round the curve to twenty miles an hour, drivers of south-bound trains have an ascent for two miles at 1 in 70 on to the Forth Bridge, and north-bound trains face a similar, though shorter, grade up to Dalgetty.

From every intermediate stop, also, the trains have to accelerate up steep gradients, in some cases, indeed - as in both directions from Arbroath and Montrose, and southwards from Aberdeen - long and arduous climbs. The consequence has been that most of the heavy modern East Coast expresses have needed “double-heading” - that is, the provision of an assistant locomotive - over this section. The new type of engine had to be sufficiently powerful to obviate this.

It was decided that to give an increased tractive force to enable the engines to get away more rapidly from these frequent stops and slowings, and also to move these heavy trains at higher speeds up the banks, the driving wheels should be reduced in diameter from the 6 ft 8 in of the “Pacifics” to 6 ft 2 in, and the diameter of the cylinders increased from the 19 in of the high-pressure “Pacifics” to 21 in. The next essential was to provide greater adhesion, so that this increased power might be transmitted to the rails without slipping, and the decision was made to use eight-coupled instead of six-coupled driving wheels.

Why It Was Designed

These points are important, as “Cock o’ the North” was not designed, as has been widely supposed, for high-speed long-distance running, but for the difficult conditions of the Edinburgh-Aberdeen route. It was the first eight-coupled locomotive built for express passenger service in Great Britain.

However desirable it might have been to provide the engine with a leading four-wheeled bogie, the increased length would have made it necessary to replace the turntables along the route by tables of larger diameter. It was not thought necessary to incur this additional expense, and the locomotive was therefore designed, like the “Moguls”, with a two-wheeled radial truck at the leading end. Another pair of wheels at the rear end carries the immense firebox, and the wheel arrangement of the engine is thus the 2-8-2, or “ikado” type, as it is generally known.

Examination of the internal economy of the “Cock o’ the North” shows that the designer of this notable locomotive - Mr. H. N. Gresley, the Chief Mechanical Engineer of the LNER, - has adapted to British conditions certain of the principles which proved so effective on the Paris-Orleans Railway, and has incorporated them in the engine.

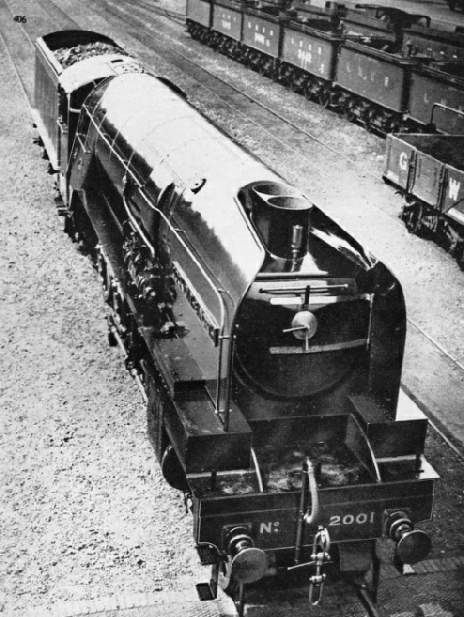

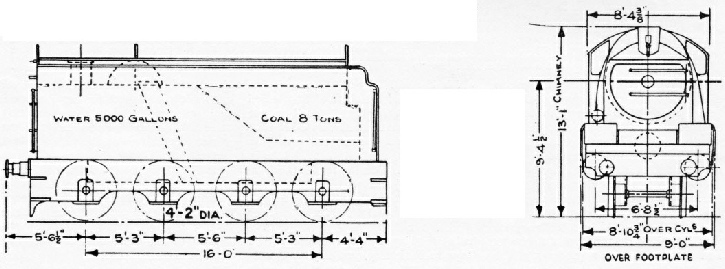

THE TENDER contains an automatic water pickup apparatus (shown dotted) to the left of the coal-space.

HEAD-ON DIMENSIONS should be compared with the fine view of this locomotive shown below.

The fine sectional picture of the engine, which appears below, reveals what a mass of detail has been crowded within the smooth external casing of the locomotive. It also shows the difficulties experienced by the designer of the modern locomotive in compressing, within the narrow limits of the British loading gauge, all the working parts of an engine capable of exerting over 2,000 hp on the draw-bar of it train.

The magnificent centre-spread to this photogravure supplement: a fine broadside photograph of No.2001 and a corresponding sectioned cut-away drawing of the locomotive. In addition to the explanatory tabs, there are a further 52 numbered items, each identified by the key in the top right hand corner of the centre-spread.

At a working pressure of 220 lb per sq in, steam passes from the boiler through a series of long narrow slots up into a cavity of pressed steel, which has been riveted on to the top of the boiler at the rear of the dome. From the regulator the steam passes into a main steam-pipe having the unusually large diameter of 7 in. The next stage of its journey is through a 43-element superheater, from which it is led down to the cylinders.

Large poppet-valves of 8-in diameter admit the steam to the cylinders, and 9-in valves are provided for the exhaust; the valves are worked by a rotary cam arrangement, instead of the ordinary Walschaerts valve-motion.

The last stage of the journey of the steam is into a blast pipe which branches into two, leading up to a double chimney which has three telescopic sections from the bottom to the top, and is known as the “K.C.” blast-pipe, after its designer, Monsieur K. Chapelon [sic], of the Paris-Orleans Railway.

All these arrangements so facilitate the passage of the steam that the engine is capable of doing high-speed work with heavy trains at no more than ten per cent cut-off - that is to say, steam is admitted for one-tenth of the stroke only, and for the remaining nine-tenths does its work by expansion.

FACTS AND FIGURES OF THE “COCK O' THE NORTH”. Cylinders (three) diameter 21in; stroke 26 in. Driving wheels, diameter 6 ft 2 in. Heating surface, tubes and flues, 2,477 sq ft; firebox, 237 sq ft; superheater, 776.5 sq ft; total, 3,490.5 sq ft. Firegrate area, 50 sq ft. Working pressure, per sq in, 220 lb. Tractive effort (at 85 per cent working pressure), 43,460 lb. Adhesion weight, 80½ tons. Weight of engine (in working order) 110¼ tons. Coal capacity of tender, 8 tons. Water, 5,000 gals. Weight of engine and tender, 165½ tons. Length of engine and tender (overall), 73 ft 8½ in.

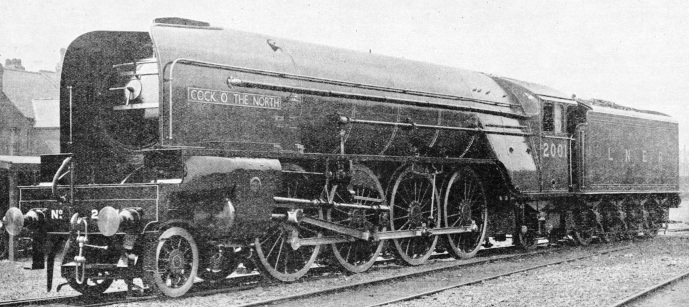

One result of this ultra-short cut-off working is that the pressure at which the steam is finally exhausted is very low, and there would be a tendency for it to drift along the top level of the boiler and obscure the front windows of the driver’s cab, were special precautions not taken to prevent this. It is here that the external casing at the front end of the engine, with its wings on either side of the smoke-box, serves both as streamlining and also to make a strong up-current of ail when the engine is running at speed, which lifts the exhaust steam from the double chimney, and carries it well clear of the cab.

The cab-front also is V-shaped, to assist in the streamlining effect, but, despite the enormous size of the boiler, there is an excellent look-out ahead. Inside the external boiler casing there is found another aid to efficiency in the feed-water heater, of the A.C.F.I. type, which uses some of the exhaust steam in order to heat up the feed-water on its way from the tender into the boiler. This means that less heat is required inside the boiler to convert the feed-water into steam.

A novelty is provided in the shape of a chime whistle in front of the chimney, which was the only convenient place in which it could be put. The tender is of the standard LNER eight-wheeled type. “Cock o’ the North” is the heaviest locomotive built, up to the time of writing, for passenger service in Great Britain, and weighs 110¼ tons in running trim; with the tender the total weight is 165½ tons.

Shortly after the “Cock o’ the North” had emerged from Doncaster Works, a test run was made, with a train weighing 650 tons, from King’s Cross to Barkstone, just beyond Grantham, and back. The long gradient to Stoke Summit, partly at 1 in 200 and partly at 1 in 178, was surmounted at an average speed of a mile-a-minute for the whole distance, and without speed at any time falling below 56 miles an hour. The engine developed at the draw-bar the hitherto unprecedented figure for Great Britain of 2,090 hp.

Whether we like it or not, locomotive fashions are fast altering. Both internally and externally revolutionary changes are being made, and from recent developments - of which the “Cock o’ the North” is only one example - it is clear that we must accustom ourselves to locomotives unlike those which have become familiar.

Those who lament the radical external changes in locomotive design sometimes forget that higher and even higher speeds are being called for in this hurrying age. The greater the speed the more potent is the resistance of the air through which the vehicle passes. Streamlining has become essential for all vehicles designed for rapid motion, and we must expect, therefore, that streamlining should be extended to the steam locomotives of the future. It is not the aim of the designer merely to obtain higher speeds. If he can lessen the resistance at high speeds coal consumption will be reduced, and efficiency will be increased proportionately. The “Cock o’ the North” is one of the heralds of the new order of things in the locomotive world.

FROM THE FRONT the feature of the “Cock o’ the North” that chiefly interests the layman is the pair of side-plates, curving upwards to form “shoulders”. The object of these side-plates is to aid visibility from the cab-windows when the engine is running. Owing to the shape of the side-plates a strong current of air sweeps upwards, carrying the exhaust steam and smoke with it clear of the cab-windows.

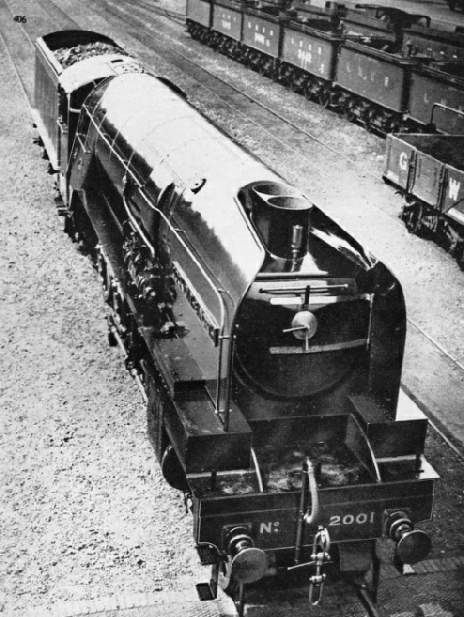

LOOKING DOWN ON THE “COCK O’ THE NORTH”. The double chimney is clearly seen from this viewpoint, which also reveals how the front of the cab is V-shaped, in order to assist in the streamlining effect. The excellent look-out ahead, despite the size of the boiler, is also apparent.

You can read more about “108mph on the LNER”, “A Test Run on Cock o’ the North” and “Experimental Locomotives” on this website.

Visit the Cock o’ the North website.

An existing “Pacific” locomotive was rebuilt in the Paris-

An existing “Pacific” locomotive was rebuilt in the Paris-