LOCOMOTIVES - 55

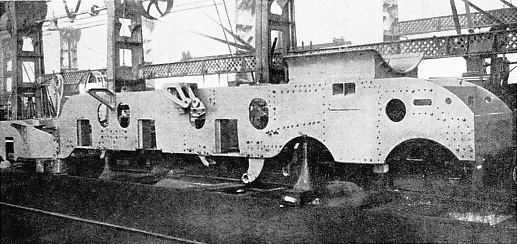

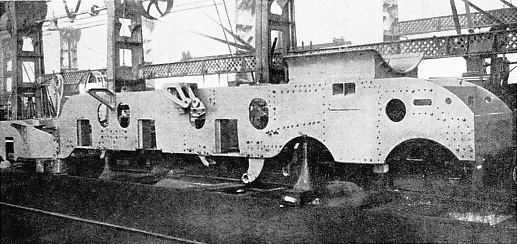

BEGINNING TO BUILD A “PACIFIC” EXPRESS LOCOMOTIVE AT DONCASTER WORKS. The main frames in position.

AS a house is built upon a foundation, so with a locomotive engine. The locomotive “foundation” consists of the two “main frames”, running parallel to each other throughout the whole length of the engine. In British locomotives the frames are of steel plate, about 1¼ inches thick, and from 2 to 3 feet deep; they are set up on edge and very strongly connected together by cross-bracings, to that they may keep at exactly the right distance from each other. The front ends of the frames are usually prominent at the leading end of the engine, supporting the smokebox on which the chimney stands, and extending forwards from there, like two knife edges, to the buffer beam. In America, curiously enough, the “plate” frame has never become popular, but “bar” frames are used, built up of steel bars suitably arranged as a kind of lattice-work; or, nowadays, of steel castings.

In the course of erecting the engine at the works where it is built, the first operation is that of laying down the main frames. To them the cylinders are bolted, together with all the details of the “motion”, which controls the entrance of steam into the cylinders and its exit from them, and also transforms the straight-line motion of the pistons in the cylinders into the circular motion of the driving wheels; the two ends of the boiler - the smokebox and the firebox - are then firmly mounted on the frames; and finally the whole of the engine, frames, boiler, cylinders and motion, is lowered onto the wheels. Thus the initial job in locomotives building is that of preparing the frames. They are first cut to the right size, and then openings are cut out of them to fit over the wheels. These openings are rectangular in shape, as they have to house the axle-boxes, which transfer the weight of the engine on to the wheels.

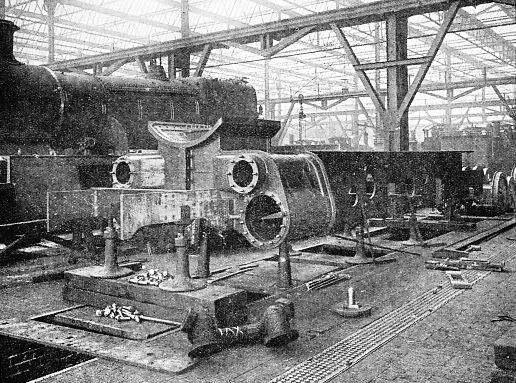

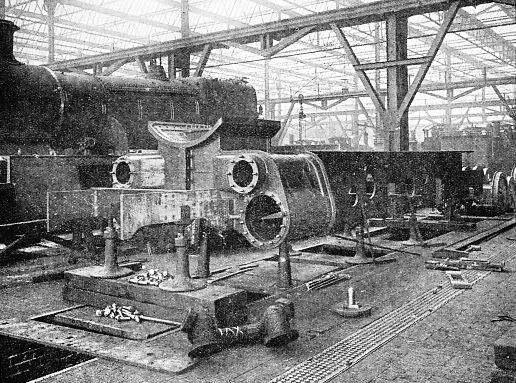

BUILDING AN ENGINE AT SWINDON WORKS: main frames, showing cylinders and saddle for smoke-box in position.

The problem of “bearings”— that is, the points where two metallic surfaces rub together when the engine is in motion — is vastly different in a full-size locomotive from what it is, say, an “0” gauge model. In the latter a round hole in the frame to house the axle, and a drop of oil occasionally, provide together all that is necessary for efficient running. But the friction in, say, the driving axle-box of a modern express engine, where a weight of some 10 tons has to be transferred from the engine-frame on to the axle, and where the two may be rubbing together continuously for hours at a stretch, is a serious matter. The difficulty is got over by making the bearings as long and as large as possible, by lining them with special “anti-friction” metals — or alloys which have proved themselves the best able to resist friction — and then by very efficient means of lubrication.

The same applies, of course, to cylinders and motion, and nowadays the oil is usually fed to the moving parts by some means of “forced” lubrication, under pressure. A mechanical lubricator numbered (8) appears in one of the photographs on this page; it has fourteen “feeds” to different moving parts of the engine. Very often now this lubrication is carried on by an apparatus inside the driver’s cab, so that he can see all the time whether the various vital parts of the motion are getting their proper supply of oil. In the old days this meant a walk round the front of the engine while it was in motion, but all such perilous practices have long since been done away with. Even with all these precautions, however, engines will sometimes “run hot”, by small grit getting into the bearings, or from other causes; and running hot means a temporary withdrawal from service, until the defect has been remedied.

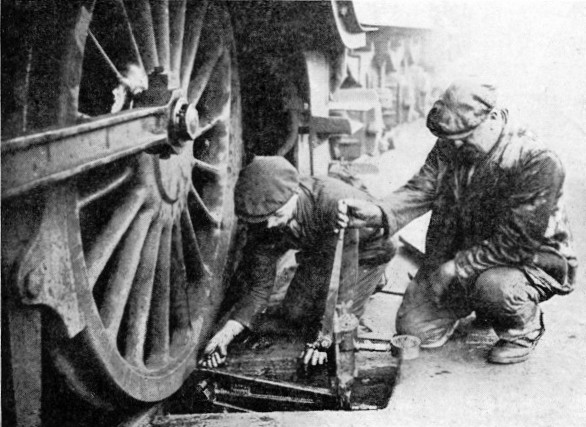

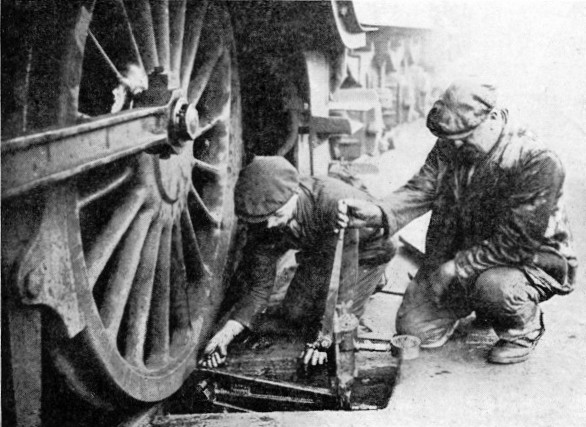

PORTABLE APPARATUS for Measuring Wheel-Loads, L.N.E.R.

Between the main frames of the engine and the axle-boxes there are interposed the springs, which save the boiler and the mechanism from being jarred excessively, as the engine passes over the joints in the rails and over the switches and crossings in the track. In the locomotive, too, the springs serve another important function. By their particular degree of adjustment, the proportion of the engine weight coming down on to any one pair of wheels can, within limits, be varied. This enables the right proportion of engine weight to be brought down upon the driving-wheels, for the purpose of adhesion; indeed, the various springs are all adjusted with the greatest care, on a special kind of weighbridge at the engine works, as the final operation before the engine takes the road, so that each pair of wheels may bear its proper share of the total weight. On the L.N.E.R., too, a portable machine has been devised — as you may see in the illustration above — for checking these axle weights at the engine-shed.

Next in order for our consideration come the cylinders. Every locomotive has at least two cylinders, and sometimes there are three, or even four. In a two-cylinder engine the two cylinders are either bolted outside the main frames, where they can be seen, and are known as “outside” cylinders; or, in “inside” cylinder engines they are fixed between the frames. The “inside” position has for many years been favoured by British engineers, both because the disturbing forces set up by the swinging round of the heavy connecting rods are nearer the centre-line of the engine, which tends thus to ride more steadily, and also because inside cylinders make for that neatness of outline of which we are so fond in this country.

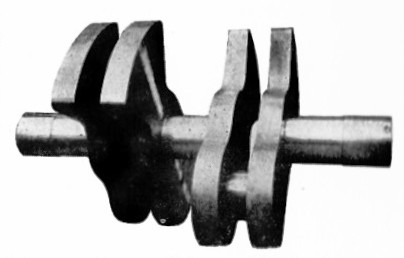

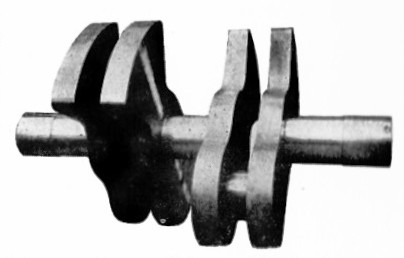

DRIVING AXLE of a “Castle” class engine, Great Western Railway, showing balanced cranks.

But the disadvantage of inside cylinders is that the driving-axle of the engine must be “cranked”, or forged into a hairpin shape in two different places, to allow of the connecting rods turning the axle and driving the engine. This is a source of weakness, and the more so as the size of cylinders is increased. Another disadvantage of the inside cylinder is that it is much more difficult to get at, in the event of any repairs being necessary. The latter is so important a consideration that the preference of locomotive engineers in this country has now veered round in favour of outside cylinders, even in two cylinder engines. Three cylinder engines have one cylinder inside and two outside, and four cylinder engines are provided with two inside and two outside cylinders.

The locomotive designer in this country works under considerable difficulties, owing to the narrow limits of space into which his engine must fit in order not to foul any of the structures over or at the side of the line. These considerations seriously affect the size of cylinders in our bigger engines. The biggest outside cylinders which a British locomotive can carry without fouling the platforms are of 22 inches internal diameter; they may be seen, for example, on the big 4-6-4 tank engines of the Southern Railway. Between the frames the engineer is also badly cramped and 21½ inches represents the largest internal diameter tried her yet in this inside position.

But the boilers of to-day have increased to a size capable of supplying with steam larger cylinders even than those of 22 inches diameter. It has become necessary, therefore, to use more cylinders than two; and the practice has consequently arisen of fitting the biggest engines with three or four cylinders, two outside and one or two inside, and all taking steam at high pressure direct from the boiler. This is known as “simple” propulsion, by contrast with “compound” working, wherein the third and fourth cylinders use “second-hand” steam which has already done part of its work in the first two high-pressure cylinders.

The two “cranks” of a two-cylinder engine are not fixed opposite each other, like the pedals of a bicycle; if they were, there would be a very awkward “dead-centre” in both cylinders, when the two pistons both stopped, at the same time, near the end of their travel. No steam would be able to enter either cylinder, and the engine would refuse to start. Instead the two cranks are arranged with a right-angle between them, and this is why you hear four puffs from the chimney every time the driving wheels go round, and not two, as you would if the cranks were opposite and the puffs came out in pairs. In a four cylinder simple engine the four cranks divide up the circle into four equal parts, of a right-angle each, and the eight puffs to each revolution of the driving wheels do in this case get thrown out of the chimney two at a time; so the four cylinder and the two cylinder engines puff in just the same way.

But a three cylinder simple engine can always be distinguished by its rapid puffing; in this case there are only three cranks to divide up the circle, into three angles of 120 degrees each, and there are therefore six independent puffs to each revolution of the driving wheels. The home of the three cylinder simple is the London and North Eastern Railway, which has large numbers of such engines ; there are the big “Pacifics” of the “Flying Scotsman” type, the three-cylinder “Mogul” 2-6-0’s, the North-Eastern section “Atlantics” of class “Z”, and many other types. The “Pacifics” have three 20-inch cylinders each, but in most of the other three-cylinder types the cylinders are rather smaller. Then, of four-cylinder engines, the Great Western “Castles” and “Stars” are perhaps the most famous, with 16-inch and 15-inch cylinders respectively; the L.M.S. “Claughtons” and the big 4-6-0 engines of the Lancashire and Yorkshire type are other well-known examples.

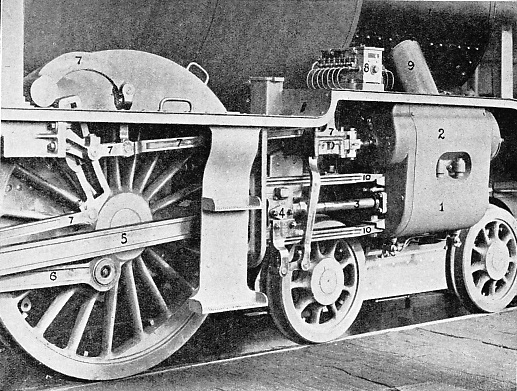

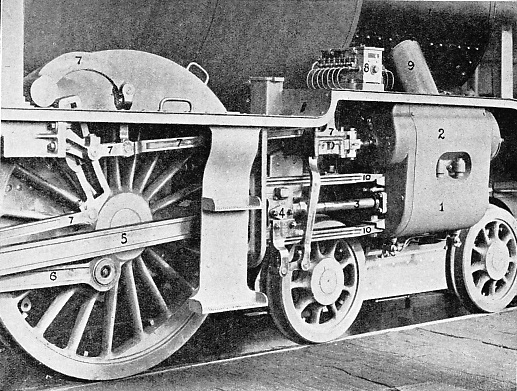

A NEAR VIEW OF THE VALVE-MOTION.

You will notice in this photograph the end of the “piston-rod” (numbered “3”) coming out of the cylinder (“1”), and terminating in the “cross-head” (“4”), which slides evenly to and fro between the “slide-bars” (“10”); the long “connecting-rod” (“5”) joining the cross-head to a pin on the driving-wheel, and so changing the to-and-fro motion of the piston into the circular motion of the wheel; and, last of all, the “coupling-rod” (“6”), which pins the big coupled wheels together, and so increases the grip of the driving-wheels on the rail. Above the cylinder is the “piston-valve” chamber (“2”), where is carried out the important work of admitting the steam into the cylinder, and letting it out again. The motion which operates the valves I have marked “7”, and the main steam-pipe from boiler to cylinder is numbered “9”. No. “8” is the automatic lubricator for the cylinders, valves and motion.

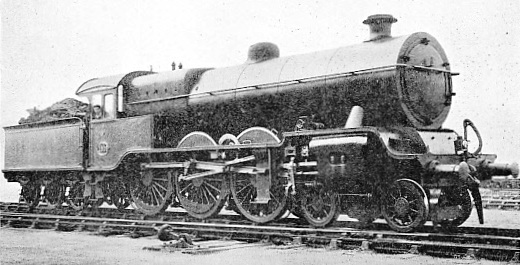

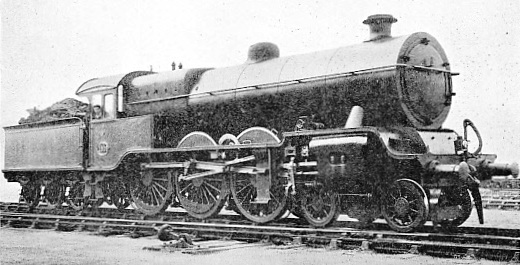

LMS FOUR-CYLINDER 4-6-0 EXPRESS ENGINE, WITH OUTSIDE VALVE-MOTION.

At this stage it is well to say something about the valve-motion, as certain references in the last paragraph you may not have fully understood. The valve-motion, or “expansion’’ gear, is that vastly important part of the mechanism of the engine which both regulates the admission of steam to the cylinders and also lets it out again on the completion of its work. In modern locomotive designs the tendency is to arrange the valve-motion on the outside of the engine as well as the cylinders; and for the same reason — that in such a position, though it may not make for beauty, it is readily accessible. A photograph of an outside valve-motion, of what is known as the “Walschaert” type, appears above, by which you will see that it is a complicated arrangement of rods, worked off certain of the chief moving parts of the engine. In the picture this motion bears the number (7). Other motions, such as the Stephenson link-motion, which is almost always arranged between the frames, are actuated by “eccentrics”, which derive their name and their motion from the “eccentric” way in which their centres are fixed on to the driving-axles.

At each end of the cylinder there are openings in its walls known as ports; they are for the admission and exit of the steam. Flat slide-valves in the older engines, and circular piston-valves in the newer, both conduct the steam into the cylinder, on its entry, and provide a passage for it towards the chimney, on its exit. With many outside-cylinder engines nowadays you can see the circular chamber, or “chest”, housing the piston-valve above the cylinder that it serves; it is numbered (2) in the photograph above.

We will assume that the port at one end of the cylinder is open to steam, which flows in and pushes the piston from that end of the cylinder to the other; the complete travel is known as the “stroke”. The piston pushes the piston-rod (3), to which it is attached and which is carried through the back end of the cylinder (1); this rod terminates by attachment to the cross-head (4), which slides securely to and fro between slide-bars (10). Then between the cross-head and the crank-pin in the driving-wheel (or the crank in the axle, in the case of an inside-cylinder engine) there stretches the connecting-rod (5), which changes the to-and-fro movement of the piston into the circular motion of the wheel.

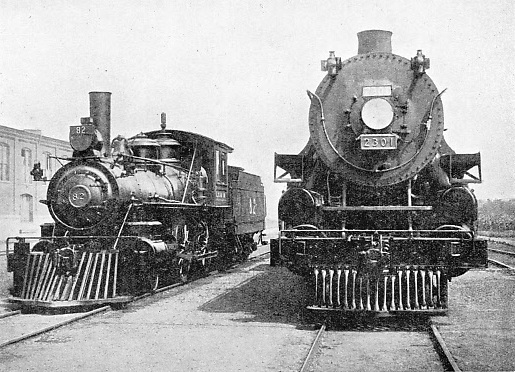

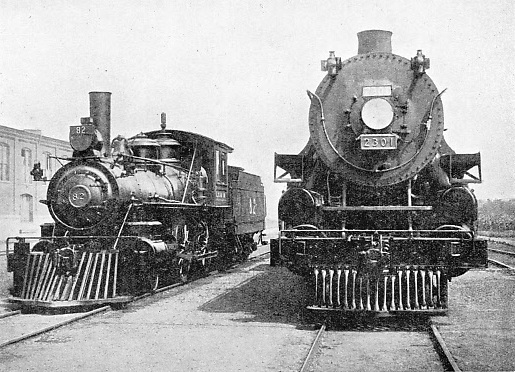

EARLY 4-4-0 AND MODERN 4-6-2 CANADIAN ENGINES: notice how the big right-hand engine overhangs the track on both sides.

The moment that the wheel has turned beyond the point at which the crank-pin is at its farthest distance away from the cylinder, the piston, of course, begins to move backwards. But the cylinder is still full of the steam which pushed the piston in the forward direction; how is it to get away? Here the slide-valve or piston-valve functions; and by its peculiar design the same valve that admitted the steam through the front port, and is now admitting it through the port at the opposite end of the cylinder, provides a clear exit-passage through the former port away into the smoke-box and so to the chimney. Each one of those small bodies of steam pushed out of the cylinders by the pistons forms one of the regular puffs that are thrown out of the chimney when the engine is in motion. Thus the valve has to move at a time and at a speed all its own, and altogether different from the movement of the piston. When the piston is nearly at rest, at the end of its stroke, the valve has to make a quick movement, so as to admit the steam freely at one end of the cylinder, and as freely to conduct it away at the other. On the other hand, when the piston is travelling at its full speed, in the middle of the stroke, the valve is moving relatively slowly.

The valve has another very important function. Steam is not admitted to the cylinder during the whole time that the piston is travelling from one end to the other; the boiler of the engine could never supply steam rapidly enough for that. At the moment of starting, steam is admitted for about three-quarters of the piston travel, and is then “cut off” by the valve, and being at a high pressure it expands for the remainder of the stroke. Then, as the engine gets into speed, the driver is able, by the manipulation of the valve-gear, to bring the point of “cut-off” farther and farther back, until perhaps the engine is cutting off in the cylinders at no more than a quarter or even a fifth — 25 per cent, or 20 per cent. — of the stroke.

This is known as “expansive working”, because so much use is made of the expansive properties of the steam; and in general, the more the use made of expansion—that is, the earlier the rate of cut-off possible in the working of the engine — so much the more efficient is its performance. The driver makes these adjustments of cut-off by means of his reversing wheel and screw (or in earlier engines by means of a lever), and from the various “notches” which were provided in order to fix the old lever in different positions, has come the well-known nickname of “notching up”, to indicate when the driver reduces the cut-off. The same reversing wheel and screw is used to reverse the engine entirely; this simply means that the driver, by screwing his wheel right over, moves the valves on their faces in such a way as to let the steam into the opposite end of the cylinders. So the functions of the valves are exactly reversed, and the engine moves backwards instead of forwards.

Before closing this chapter, a word of explanation is needed in regard to compound locomotives. The idea behind compounding is to divide the expansion of the steam into two stages. Two sets of cylinders are provided, therefore: “high-pressure” cylinders, taking their steam direct from the boiler, and passing it, in a partially expanded state, into a “receiver”, and “low-pressure” cylinders, taking their supply from the receiver, and completing the expansion. The three-cylinder compound usually has one high-pressure cylinder inside, and two low-pressure cylinders outside the frames; in the four-cylinder compound there are two inside high-pressure cylinders instead of one.

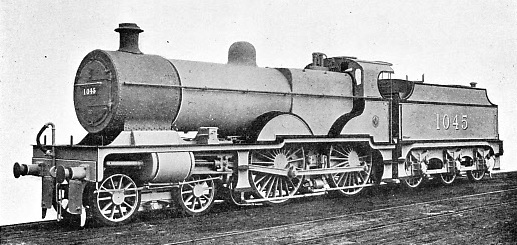

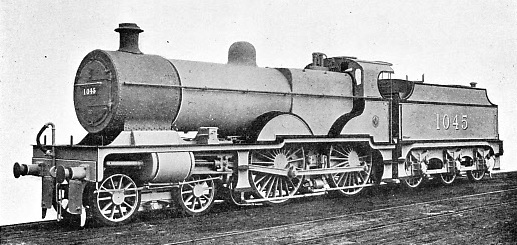

In compound locomotives arrangements are generally made whereby, on starting, the driver can admit boiler steam straight down to the low-pressure cylinders; otherwise they would be very bad starters. Once they are well away, ordinary compound working is begun. Well-designed compound locomotives are amongst the most efficient — on the basis of work done in proportion to coal burned, which is the truest test of efficiency — in existence. Compounding has never found very great favour in this country, chiefly because the systems tried here, until recently, have had certain defects which have handicapped the engines badly. But the three-cylinder system developed on the late Midland Railway has been so successful that there are now round about two hundred of these famous 4-4-0 engines, carrying numbers between 1000 and 1200, working over nearly all the main lines of the London, Midland and Scottish Railway in both England and Scotland.

In America, also, nothing much has been done in the way of locomotive compounding, but when we turn to the Continent of Europe, it is safe to say that the majority of the larger locomotives in its various countries are of compound types. France and Germany, in particular, are the home of compound engines, and those of you who have travelled over the Northern Railway of France between Calais and Paris will have had, no doubt, all the demonstration you need as to what can be done by their big compound “Pacifics” in the way of fast travelling. On the Calais and Boulogne boat expresses, which are only allowed one hundred and ten minutes in which to cover the 109 miles from Paris to Abbeville, they think nothing of gaining time with huge trains of 500 tons’ weight. But it is probable that we shall see a further development of locomotive compounding in this country ere long.

MIDLAND THREE-CYLINDER COMPOUND 4-4-0 ENGINE.

You can read more on “How a Locomotive is Built”, “Halls of the Giants” and “Testing a Locomotive” on this website.