An Invention of the Simple Geared Drive with bevel Wheel and Pinion, Which Anticipated the Live-Axle and Cardan Shaft Principle of the Modern Motor-Car

LOCOMOTIVES - 45

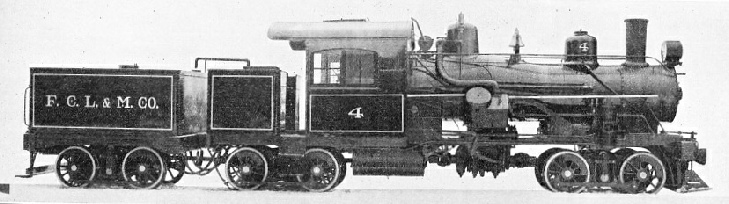

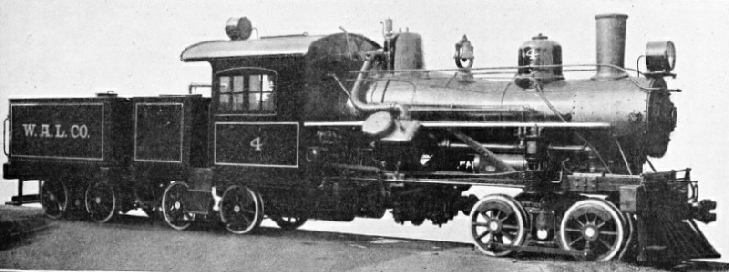

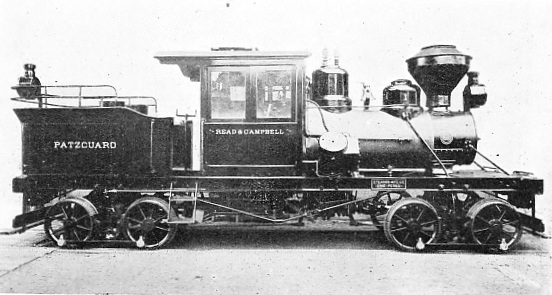

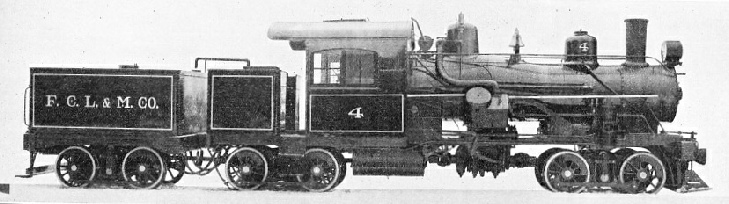

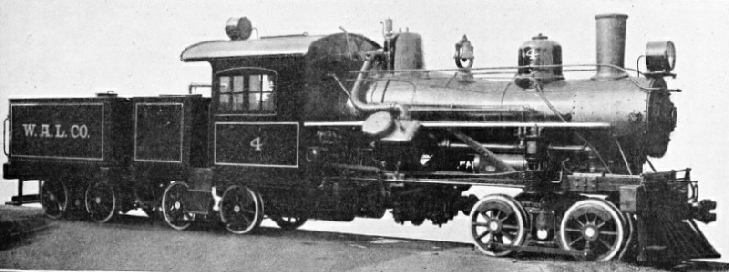

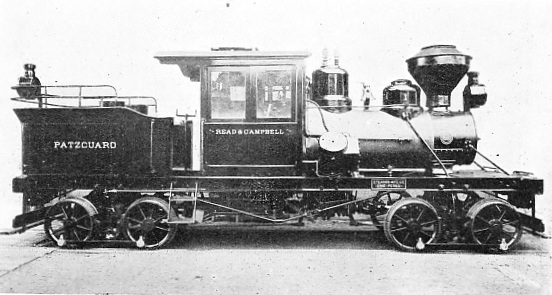

A PIONEER HEISLER GEARED LOCOMOTIVE. This type was specially evolved to meet the peculiar requirements of the lumber industry. A wooden cab was fitted, but, proving unsatisfactory, later locomotives were provided with an all-steel cab.

INDUSTRY has led the steam locomotive into many strange places, as the observant traveller, in the course of his world-wide wanderings, cannot fail to have remarked. Probably this activity is more pronounced in connexion with the lumbering trade than with any other ramification of industrial endeavour, because from their nature the great timber preserves are generally far away from the beaten track. Logging is beset with many perplexities. Under modern methods the forest is stripped of its merchantable timber with astonishing speed, and it is incumbent to move the log to the mill without delay.

Experience has proved the railway to stand unrivalled for lumber haul, but the law of economics insists upon a railway differing -vastly from the line that speeds us in comfort from city to city. Even the most crude railway of standard gauge is likely to cost from £1,200 to £2,000 per mile for material alone. The road for the logging rail invariably follows the run of the land; grades and curves are of secondary importance. Heavy switchback serpentine routes are the result, with banks as steep as 1 in 8 and curves of 76 feet radius. Where the ascent is exceptionally heavy there is recourse to zigzags, with the train sawing its way up and down the hill-side.

In logging hauling power is of more significance than speed, but the nature of the track is adverse to the effective employ-ment of the familiar “direct-connected” locomotive, so-called from the reciprocating parts of the cylinders being connected direct to the driving wheels. Its rigid wheel-base and relatively low factor of adhesion are against its profitable use. With the development of the lumbering industry upon the North American continent, and the recognition of the limitations of the direct-connected locomotive in this application, inventive genius became stimulated in the effort to evolve an engine essentially for such duty.

American designers turned to the work of the British pioneers and their geared locomotives, and drew freely upon their conceptions to meet the domestic situation, afterwards adapting the details to local conditions. Varying success was recorded, but, for the most part, one and all designs found the sharp curves fatal to triumph. One American inventor sought to apply the differential gear, common to the motor-car, to avoid shipping the drivers on the sharp curves, but he overlooked the fact that nearly all curved tracks form a warped surface. The result was that the diagonally opposite driver of each truck became more heavily loaded than its companion, which provoked the exasperating habit of the alternate driving wheels spinning when rounding a curve. A similar effect was produced when any one of the drivers of the locomotive happened to encounter a slippery patch upon the rails.

MOVING LUMBER OVER A SWITCHBACK WITH A GRADE OF 1 IN 10. The high tractive effort of the Heisler Geared Locomotive, due to the fact that all wheels are drivers, ensures haulage of heavy loads over the steepest banks.

Notwithstanding the inherent difficulties of the problem, the lumbering trade became more and more insistent for a locomotive adapted to its peculiar needs. The various locomotive manufacturing enterprises were incessantly importuned to come to the assistance of the sorely affected industry. Among the firms approached in this manner was the Brooks Locomotive Works, of Dunkirk, in the State of New York. They were asked for a locomotive adapted to rough mountain tramway service, capable of operating, safely and effectively, upon grades of i in 10 and curves of 95 feet radius.

Inception of the Heisler Design

One of these inquiries happened to be misdirected. Instead of being sent to the Brooks Locomotive Works it was addressed to the Dunkirk Engineering Company, owned by Mr. Edward Nichols, the President of the Brooks Locomotive Works. Confusion of the two firms was probably responsible for the mistake upon the part of the inquirer, a Mr. Addington, of Little Washington, North Carolina. What he wanted was a small locomotive, weighing about 10 tons, for service in a lumber camp among the mountains in the northern corner of his home state. He intimated his readiness to place an order with the Dunkirk Engineering Company immediately, if it would positively undertake to deliver such an engine in 60 days.

The company in question, while specializing in the manufacture of hydraulic, handling, and other special machinery entering into the manufacture of locomotives, did not engage in the production of the latter, but the inquiry happened to be passed on to the mechanical superintendent. He was a young man, Mr. Charles L. Heisler, who had recently completed his engineering training at Cornell University, where he had won distinction by his original investigation, and who had made a special study of the locomotive.

As the engine desired was so small Mr. Heisler was sorely tempted to recommend the acceptance of the order. Confident of being able to satisfy the specifications required, he saw the opportunity to present something entirely new in locomotive design. He was fully cognizant of what the British pioneers and his contemporaries in the United States had achieved in this field, and realized the circumstance that a geared locomotive, conceived along certain lines, would meet the rigorous conditions. His conception aimed at a more effective and simpler form of construction through reduction of the number of gears generally embraced in this form of unit, with incorporation of some of the proved features of the side-rod coupled type of standard locomotive.

A certain amount of pioneering was inevitable, and, upon reflection, he was compelled to acknowledge that the suggested time limit of 60 days did not offer sufficient opportunity for invention and development. With great reluctance he had to point this fact out to his chief, who concurred in the lack of opportunity to conduct original investigation and research. Accordingly, it was decided to acquaint the anxious customer that, in the circumstances, there was no possible chance of the company being able to meet his request.

First Heisler Geared Locomotive

Happily the general manager learned that no other manufacturer was in the position to compete with the offer of a locomotive designed for the duty, and so he wrote to Mr. Addington requesting an extension of 30 days for delivery, to enable them to get out a new and special design To this the client agreed. Thereupon Mr. Heisler concentrated the whole of his time upon the new idea; he devoted from twelve to fifteen hours a day upon the study and evolution of new arrange-ments for the locomotive trucks, motor-engines, and other features, making detailed sketches, and producing a mass of constructive data. This was then submitted to the process of elimination, culminating in the selection of one design which it was concluded would be the easiest to build in 60 days.

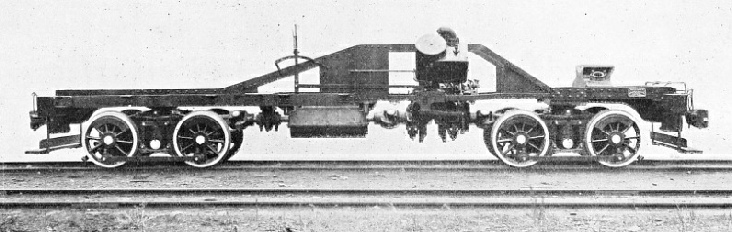

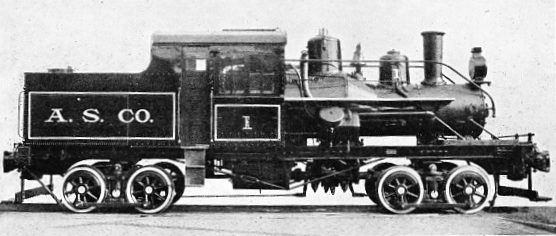

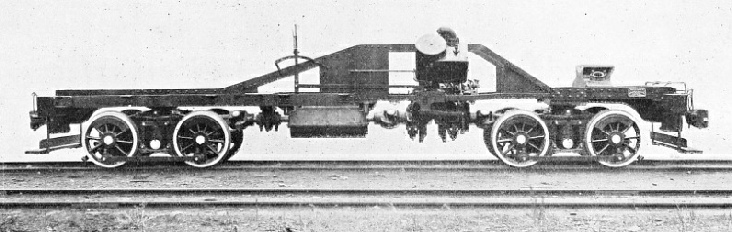

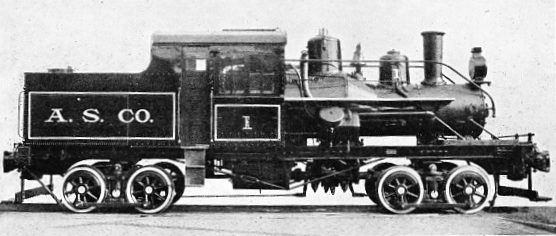

TWO-TRUCK HEISLER GEARED LOCOMOTIVE WITH I-BEAM FRAME. This type of frame is favoured for eight-wheelers weighing up to 92,000 lb. For larger and heavier engines with eight, and twelve driving wheels, the diamond frame is used.

The conception was something entirely new in locomotive design, and, because of its novelty, advantage was taken of the law protecting originality. An interesting feature of this patent specification is that the drawings illustrating the principle had to be copied from those which served for the first locomotive, built to the order of Mr. Addington. In this instance, therefore, the patent illustrations happen to be a faithful record of the first Heisler geared locomotive, as it is generically called - an incident difficult to parallel in the history of patents. This pioneer was designed, built and tested in about 70 days, and it was handed over to the purchaser not more than 60 days after the receipt of the formal order. For purposes of simplicity, and to effect reduction in prime cost, this engine was fitted with a tubular cylindrical boiler with an internal fire-box of the usual type.

The first Heisler geared locomotive proved eminently satisfactory to its owner, and soon attracted the attention of the lumbering industry in general. It presented exactly the type of locomotive for which such diligent search and inquiry were being made. The future of the new idea appeared to be assured when, unfortunately, Mr. Edward Nicholls, who had assisted his mechanical superintendent, and who held certain interests in the invention, died. Such misfortune could not have happened at a more unhappy moment; development of the idea perforcedly had to be suspended, but the outlook cleared when the heirs of the late president graciously handed over all their interests in the patent to the inventor.

Unfettered possession gave Mr. Heisler absolute freedom to make any further arrangements he concluded advisable to continue the manufacture of his engine, and, about the end of 1893, he was approached by Mr. George Burnham, senior, at that time president of the Baldwin Locomotive Works in Philadelphia, whose interest in the invention had been aroused. Burnham handed the invention to the technicians of the extensive organization which he controlled for investigation, and to him they carefully explained all its details and recommendatory features. Burnham was so impressed as to intimate to Heisler his intention to manufacture the locomotive, at least for the time being, in the independent shops which he owned privately in Erie. Thus the manufacture of the Heisler geared locomotive entered upon the second epoch in its history.

Orders continued to pour in from the lumbering industry and from other trades in which broadly similar railway conditions obtain. The invention was thus steadily and surely gaining ground when there came another set-back through the death of Mr. Burnham. Again manufacture had to be conducted under the most difficult conditions until fortune once more came to the inventor’s aid. A capitalist resident in Erie, Mr. F. F. Curtze, was drawn to the novel locomotive through the efforts of a young engineer, Mr. Roy Swabb, who had received his early technical training in its manufacture, and who was convinced of its commercial future.

The investigations conducted by Mr. Curtze vindicating the assertions of Mr. Swabb, the first-named decided to place the invention firmly on the market. He organized the Heisler Locomotive Works in Erie, Pennsylvania, exclusively for its production, and upon a more extensive scale than had hitherto been attempted. Mr. Curtze decided to pilot the fortunes of the enterprise personally, while Mr. Swabb concentrated his attention upon the development, perfection, and manufacture of the engine. As the result of this dual commercial and technical control the locomotive has been introduced to every country throughout the world, has brought about the foundation of a new ramification in the locomotive industry, and has widened the field for its application to an extent far exceeding original expectations.

During this third and enduring period of the locomotive’s history many improvements were made to enhance its serviceability and efficiency; one of the most important of these was the embodiment of Mr. Swabb’s idea for giving extreme flexibility to the truck-frame, to allow of the engine adjusting itself readily to the warped and uneven surface common to mountain railways. Its dimensions, power, and range of action have been persistently increased, bringing units weighing up to 200,000 lb. into service not only for the movement of commercial commodities, but of passengers as well, over roads where the grades and curves render the conventional type of locomotive impracticable, and yet upon which adhesion working is imperative.

During this third and enduring period of the locomotive’s history many improvements were made to enhance its serviceability and efficiency; one of the most important of these was the embodiment of Mr. Swabb’s idea for giving extreme flexibility to the truck-frame, to allow of the engine adjusting itself readily to the warped and uneven surface common to mountain railways. Its dimensions, power, and range of action have been persistently increased, bringing units weighing up to 200,000 lb. into service not only for the movement of commercial commodities, but of passengers as well, over roads where the grades and curves render the conventional type of locomotive impracticable, and yet upon which adhesion working is imperative.

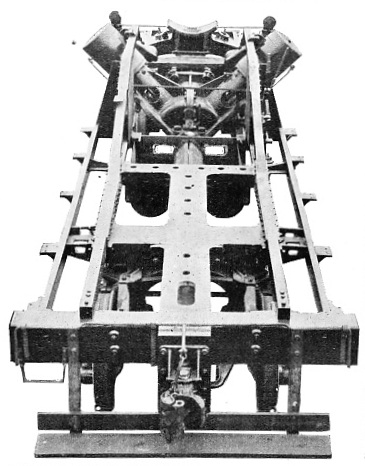

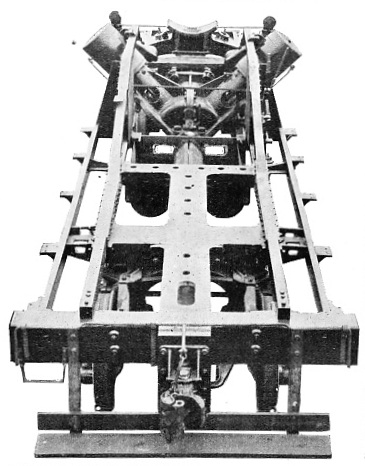

PLAN VIEW OF THE DIAMOND MAIN FRAME OF LOCOMOTIVE. Shows method of mounting the engine and transmission. The design permits the removal of the boiler and fire-box without disturbing the running gear; similarly, the latter may be taken down without dismantling the locomotive.

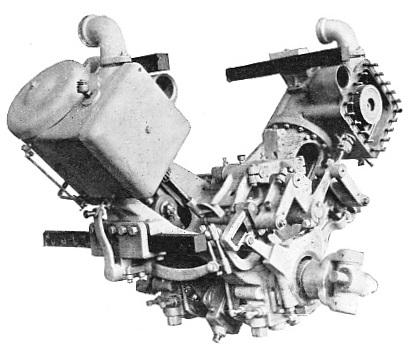

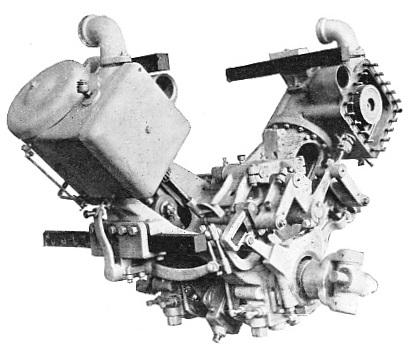

The Heisler geared locomotive possesses nothing in common with others of this class. So far as the general lines are concerned, the only familiar features are the boiler and fire-box. These, together with the usual fittings, are mounted on a trussed “I” beam, or a “diamond” frame; the former is favoured for units up to 41 tons, and the latter for those exceeding this weight. The cylinders, two in number - for purposes of differentiation they are more generally known as motor-engines - are not mounted in the horizontal or inclined position at the front end of the frame, with their crossheads connected to the driving-wheels system, but are set in the form of a widely opened vertical V, under the boiler, in front of the fire-box, thus imparting an unfamiliar tout ensemble to the engine.

The opposing cylinders, inclined at an angle of 90 degrees to one another, are bolted to the main frame and connected to a single throw crank-shaft having a universal coupling at each end. Being free from the boiler, every part is readily accessible, and it is possible to detach the motion intact, when desired, without disturbing any other part of the engine. Similarly, the boiler, which is rigidly connected to the saddle of the main frame at the front end, can be lifted clear of the main frame without interfering with any other detail, except the cab.

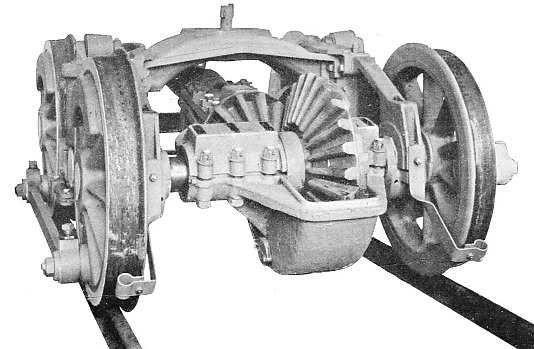

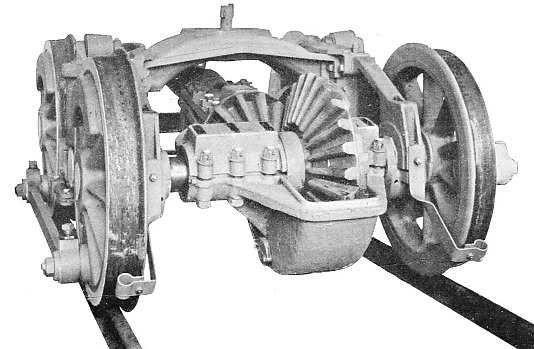

The outstanding feature of the locomotive is the gear transmission. The main frame is supported at the ends by swivelling or four-wheeled bogie trucks. The outer axle of each truck is the driver and, for this purpose, is fitted with an enclosed oil-submerged steel gear. There are only two gears - the bevel wheel and the pinion. Both are of ample dimensions and massive construction ; the master bevel is mounted upon the enlarged driving axle, while the robust pinion is suitably keyed to a large pinion shaft. Owing to the gears being mounted within a rigid self-contained enclosing gear frame, dead alignment and perfect meshing are forthcoming, giving noiselessness and minimum cost of maintenance.

SIDE VIEW OF DIAMOND FRAME OF LOCOMOTIVE. Showing one cylinder of engine, and transmission to each truck with universal couplings, thus giving flexibility for the rounding of sharp curves and safe riding over a badly laid track.

The Driving Principle

The fundamental driving principle is precisely that now universally adopted in motor-car design, providing what is known as the live-axle drive; and, be it noted, this practice was first exploited in the Heisler geared locomotive. The number of gears is kept down to the minimum; there are only two pairs for an eight-wheeled locomotive - one to each truck - and four pairs for a twelve-wheeled three-truck unit.

The drive from the engine to the two-gear trucks is through a single continuous shaft coupled to the crank and pinion shafts, respectively, by universal joints. This shaft is centrally disposed along the longitudinal plane of the engine, ensuring a simple, straight, and direct drive. In the case of the eight-wheeler, one-half of two of the couplings - one-half of three of the couplings in the twelve-wheeler - are made square, to allow the square end of the shaft to slide when the trucks swing on a curve and change the length of the centre shaft. Owing to the couplings in the central driving shaft being set so close to the centre of each truck they have very little telescopic slip, but one interesting detail is the provision of means for the easy disconnexion of the couplings, in the event of a derailment, without breaking the central shaft.

The longitudinally central disposition of the driving shaft not only gives the most effective steady drive, but brings complete protection against snow, grit, sand, and other material thrown up from the roadbed. The trucks of the eight-wheeler are exact duplicates in every respect, bringing the advantage of interchangeability; in the case of the three-truck type this duplication is preserved except in regard to the gear case and the swivel bar for the centre truck. Symmetry of design, which is such a conspicuous feature of the locomotive, imparts the further advantage of maintaining perfect balance round the curves with equal distribution of the weight upon all the wheels.

THE NOVEL ENGINE OF THE HEISLER GEARED LOCOMOTIVE. The “V” arrangement of the cylinders permits the ready withdrawal and replacement of the unit without disturbing any other part of the locomotive. It is bolted to the main frame, free of the boiler barrel, with universal couplings between engine and propeller shafts.

The outer axle of each truck being the driver, side-rods are introduced to couple the wheels on this axle to those on the second or idle axle; by this arrangement all wheels are converted into drivers, thus permitting the whole of the weight of the unit to be used for adhesion. It may be mentioned that the same gears and gear case are suitable for any gauge of track, allowing a locomotive to be changed from standard to narrower gauge or vice versa. To effect the change it is only necessary, as the case may be, to shorten or lengthen the driving axles, swivel-bars and spring bolsters, because all other parts are interchangeable.

There are two large sand-boxes for the delivery of sand under the outside wheels of each truck, so that sand can be used under all the drivers, no matter in which direction the engine may be running. The front sand-box is mounted on the top of the boiler, a short distance behind the smokestack, while the second is fitted to the rear of the water-tank with adequate provision to keep out the water. Both sand-boxes can be operated by hand or air, according to desire, and from the cab.

An Ingenious Braking System

The braking system is also ingenious, of simple design, and positive as well as highly effective in action. The braking pressure is varied by the driver through the medium of a three-way valve. When the lever is moved to the first notch, steam is admitted into the smaller of two brake cylinders, and the result is a moderate pressure upon the brake shoes. If a heavier brake pressure is desired, the lever is moved to the second position, admitting steam to the larger cylinder with simultaneous exhaustion of steam from the smaller cylinder.

When, however, the driver moves the lever to the third notch, steam is admitted into both cylinders, and the full braking pressure is instantly applied, as, for instance, in an emergency. By returning the lever to the neutral position the brakes are instantly released by steam. Owing to the character of the brake-rigging system a uniform pressure is applied to all the wheels, and there is neither binding nor loose running when rounding curves. By this compound system the braking effort can be varied according to the grade and load, and is equally effective whether steam or air, or combined steam and air, be used.

On the first locomotive of this design wood was employed for the construction off the cab, but it was found to be far from satisfactory. The uneven track, rough travelling and hard use, extreme changes in temperature, and, at times, exposure to the heat from forest fires, played havoc with the wood framing. Accordingly, a heavy and substantial steel cab is now used with floor and ceiling finished in wood.

Wood, coal or oil can be used as fuel with equal facility; the first-named is carried in a rack, the second in an ordinary bunker, and the last-mentioned, in the case of the eight-wheeler, in a tank placed above the water-tank. In the case of the twelve-wheeler, with its three trucks, the oil-tank takes the place of the coal bunker. Ample water-carrying facilities are provided, and are capable of being increased by mounting a supplementary saddle-tank on the boiler. In this event the forward sandbox is abandoned for two smaller sand-boxes placed on the deck plates above the front wheels.

The Heisler locomotive is built in ten standard classes according to size, weight and tractive effort. The first eight classes are of the eight-wheeled type, though this group is further subdivided according to design of frame. As previously mentioned, the trussed “I” beam is used for engines scaling up to 92,000 lb, while the “diamond” frame is used for those exceeding this weight, and specially designed for much heavier haulage.

NOVEL GEAR DRIVE OF THE HEISLER TRUCK.

One axle carries a heavy bevel wheel with which meshes the pinion mounted on the propeller shaft, the drive being transmitted from this to the fellow axle of the truck through side wheel-coupling rods. This method of transmission has since been universally adopted in the motor-car.

The eight-wheelers are fitted with cylinders ranging from 11 by 10 16⅜ by 14 inches, working at a pressure of 160 or 180 lb, with driving wheels 30 to 40 inches in diameter. The rigid wheel-base ranges from 18 feet 2 inches to 30 feet; overall length from 26 feet 4 inches to 39 feet. The weights in service trim extend from 52,000 to 143,000 lb; while the tractive effort, at 20 per cent, adhesion, varies from 10,400 to 28,600 lb. The smallest type is capable of working on curves of 50-feet radius. In the case of the twelve-wheelers - three-truck locomotives - the cylinders are 17 by 15 and 18 by 16 inches, respectively, using steam at a pressure of 200 lb, while the drivers are 38 or 40 inches in diameter. The rigid wheel-bases are 61 and 66 inches, and the overall lengths 48 feet 1½ inches and 53 feet 10 inches, respectively. In working order the smaller unit weighs 177,000 lb, and has a tractive effort, at 20 per cent, adhesion, of 35,400 lb; the bigger brother scales 199,000 lb, and has a tractive effort of 39,800 lb.

Throughout the timber territories of the world the Heisler geared locomotive may be seen performing duty of the most arduous character with complete success; many of these units are veterans of 25 years’ continuous operation. It has invaded the rich lumbering districts of New Zealand; in British Honduras, among the lagoons of Louisiana, the low-lying flats fringing the Mississippi, and the broken, heavily tree-clothed backwoods of Michigan, it is rendering striking performances. Probably its significance to the lumber industry is most convincingly revealed among the Cascade Mountains of the North Western States and British Columbia.

THE LARGEST AND MOST POWERFUL HEISLER GEARED LOCOMOTIVE

These are mountain railways in the fullest sense of the word. They wind and twist among the crags and shoulders in curves which appear to be hopelessly impracticable to the steam locomotive, while the banks are so steep as to seem impossible of adhesive working. The crossing of the yawning gulches from one hump to the other has involved the erection of lofty trestles of the familiar wooden type - striking manifestations of engineering achievement in themselves, but additionally impressive from the railway view-point because of their curvature and grade. The Northern Pacific Railroad maintains one such line, rising steadily at 1 in 20, including the passage of the trestle, which is 134 feet in height, set on a sharp curve, over which trains of 25 cars of logs are regularly moved by a heavy Heisler eight-wheeler.

In another instance the locomotive is confronted with a steady upward toil for 5 miles with the maximum rise of 1 in 12½, but upon this the locomotive handles ten standard railway logging trucks per trip. Possibly, however, the most amazing expression of such hauling achievement is to be found among the mountains enveloping Vancouver. This particular Canadian road has grades ranging from 1 in 10 to 1 in 6 - on one of the loftiest trestles it is 1 in 8½ - down which the logs are moved by the trailing method. A chain of baulks, in the round, are hitched end to end to form a continuous train with the locomotive at the head for haulage down the mountain slope, the while the ungainly load skids over the track between the rails. While service among the mountains reveals the great haulage capacity of the Heisler engine in possibly its most arresting aspect, operation on the level presents another. In one lumber camp with such a reach of track, the eight-wheeler conducts a regular haul of 21 cars laden with 73,000 feet of logs.

It has been pointed out how Heisler, by his conception of the simple gear drive with bevel wheel and pinion, anticipated the live-axle and cardan shaft principle of the modern motor-car. He pioneered another important development in the first locomotive built to the order of Mr. Addington. This was the all-steel-casting truck side frames and bolsters, first designed, made, and used, for his new type of locomotive, but which have since been incorporated on all freight cars of the American type. When one of the largest steel foundries in the country was requested to cast these frames, it demurred unless the thickness of the metal was increased from ⅝ to ⅞ inch. The inventor declined to accede to this demand, and, in 1892, the Pratt and Letchworth Foundry, of Buffalo, completed the work, also the gears, as stipulated.

THREE-TRUCK HESILER GEARED TWELVE-WHEELER

You can read about “Articulated Locomotives”, “The Fairlie Double-Ended Locomotive” and “The Shay Geared Locomotive” on this website.

During this third and enduring period of the locomotive’s history many improvements were made to enhance its serviceability and efficiency; one of the most important of these was the embodiment of Mr. Swabb’s idea for giving extreme flexibility to the truck-

During this third and enduring period of the locomotive’s history many improvements were made to enhance its serviceability and efficiency; one of the most important of these was the embodiment of Mr. Swabb’s idea for giving extreme flexibility to the truck-