Economical Traction for Special Services

LOCOMOTIVES - 26

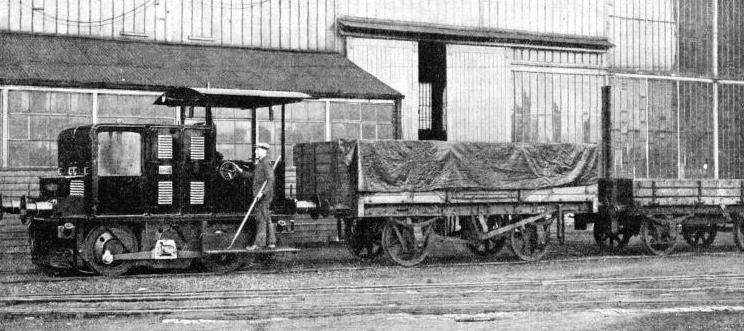

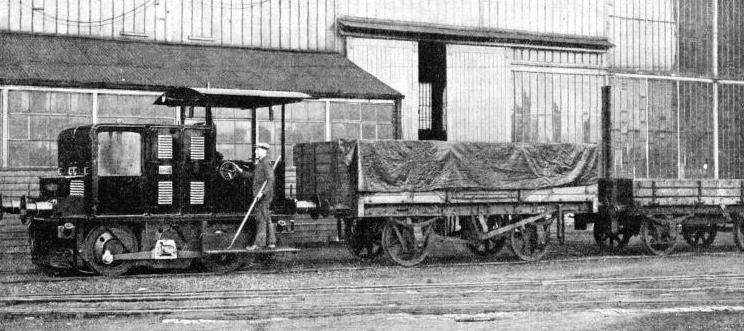

A 15-TONS DIESEL LOCOMOTIVE of 100 hp built by Sir W. G. Armstrong-Whitworth and Co. (Engineers) Ltd. The engine is of the 0-4-0 type and is 13 ft 4½-in long over the buffer beams. The photograph illustrates the ease with which shunting operations can be carried out by a single operator.

THE steam locomotive for passenger and goods transport purposes has enjoyed such a long and hitherto unchallenged reign in all countries that it has come to be regarded as a firmly established part of all railway systems. With the rapid evolution of the petrol and Diesel engines, however, this supremacy has been challenged.

The advantages of the internal combustion engine are dealt with in the chapter “British Diesel Rail Coaches”, beginning on page 609. They are claimed to be compact, low first cost, lower fuel costs, absence of boiler, the ability to develop full power from the cold condition in a few minutes, the fact that no fireman is required in addition to the driver, and better all-round convenience.

Although numerous petrol-engine locomotives have been built for haulage and shunting work and in some instances for passenger work, on both the narrow and standard gauges, and have fully demonstrated their advantages, the Diesel-engine type, in its turn, has definite points of superiority over the petrol locomotive. It is only during the past three or four years, however, that the Diesel locomotive has made any substantial commercial progress, although the earlier experimental models fully established the claims made for them.

Numerous practical difficulties were encountered in the earlier attempts to adapt the Diesel engine to railway locomotive requirements, principally in connexion with engine noise, vibration, transmission, and controls, but all of these have been overcome satisfactorily. The question of the relatively higher rate of wear of the high-speed Diesel engines selected for railway use has also received considerable attention, and the useful working life of this type of engine is now much longer before overhaul becomes necessary. The use of hardened alloy cast-iron cylinder liners - removable for replacement purposes when worn - has overcome the principal source of engine wear, namely, that of the cylinder walls.

The valve-seatings - another item of accelerated wear - are now made by inserting machined rings of hard alloy steel or an extremely hard synthetic material known as Stellite into the cylinder casting. Yet another source of fairly rapid wear, in comparison with steam locomotive practice, was found in the main connecting-rod and big-end bearings. Under the high loading pressures employed, these white metal bearings were liable to crack or break up after 15,000 or 20,000 miles of running. A special lead bronze is now employed for these bearings so that they will run satisfactorily for at least 80,000 miles under normal working conditions.

At the present time, the Diesel engine may therefore be considered satisfactory for many locomotive purposes. The Diesel locomotives and rail-cars of one British company alone had completed over eight and a half million miles of service up to July, 1934.

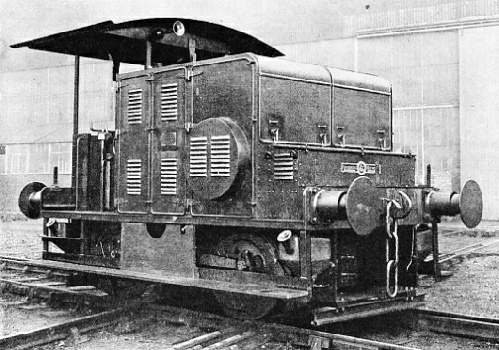

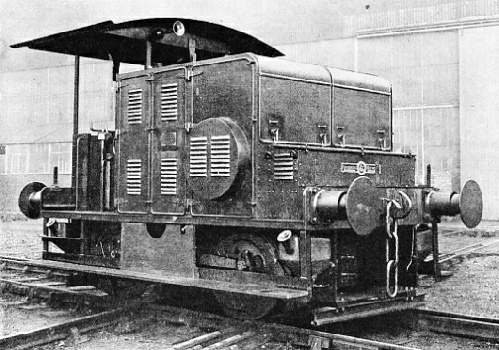

0-4-0 TYPE of shunting locomotive built by Sir W. G. Armstrong-Whitworth and Co (Engineers) Ltd, in 1933. This locomotive is equipped with a 100hp engine and weighs 15 tons.

The Diesel locomotive, at present, is normally made in much lower horsepowers and for smaller haulage efforts than the steam locomotive; it is therefore employed principally for local goods haulage and shunting or switching purposes on main line and narrow-gauge railways. It must not, however, be concluded that there is any definite limitation of size for Diesel locomotives, for, although in Great Britain the maximum size appears to be the 350 hp, 50-tons locomotive used for shunting purposes, yet on the Continent, in the United States of America, and in the Argentine, Diesel locomotives or train units of 2,000 to 4,000 hp have been in regular operation in recent years.

Since the present account is mainly confined to the smaller class of Diesel locomotives employed for shunting and goods haulage work, it may be of interest to give some general information relating to British makes of locomotive before proceeding to describe a number of typical commercial makes at present in use, both at home and abroad.

Disregarding the narrow-gauge designs of Diesel locomotives as well as those used in coal mines for haulage purposes, the standard and broad gauge models now employed range in output from about 150 hp to 350 hp, and in total loaded weight from about 15 tons up to about 50 tons.

The tractive efforts available for starting purposes range from 6,000 to 30,000 lb, and the locomotives will haul from 100 to 1,000 tons on the level, according to the size of engine fitted and the speed of working.

The usual wheel arrangement for the smaller shunting locomotives is the 0-4-0; for the larger 300-350 hp engines the 0-6-0 arrangement is adopted.

Several types of transmission systems are employed. In all examples, it is necessary to interpose some kind of reduction gear, since the driving wheels of the locomotive revolve at a much lower rate than the engine; moreover, for starting purposes and when hauling heavy loads it is necessary to have a much higher turning effort, or torque, at the driving wheels than is given at the engine's crankshaft.

The necessity for reduction gears is just as important in a high-speed Diesel locomotive as it is in a motor vehicle, for in each instance the low torque and high revolutions of the engine must be converted (by the transmission system) to higher torques and lower revolutions at the driving wheels. In addition, it is necessary to have a clutch - or its equivalent - to connect the engine to the driving wheels for starting, and to disconnect it for stopping purposes.

Methods of Gear-Changing

The smaller Diesel locomotives are normally fitted with a friction type of clutch and a two- or three-speed gearbox; a reverse gear is usually embodied in the gearbox. The most favoured form of gearbox appears to be the type having its gears of the helical or herringbone pattern, in constant mesh. Dog clutches are used to engage the different gears.

This type of Diesel locomotive is thus built on a principle similar to that of the ordinary motor-car. The mechanical gear method, while being fairly satisfactory and reliable for small locomotives, needs skill and attention on the part of the driver, and it may be noisy in operation.

In the medium and larger sizes of Diesel shunting locomotive, these objections have satisfactorily been met by the substitution of the hydraulic or electrical systems for the mechanical gear transmission. The use of oil-filled hydraulic torque converters in place of ordinary gearboxes has not only brought about more silent running, but has also made gear-changing simpler.

The electric transmission system consists in coupling the engine to a dynamo, or generator, and taking the electrical output from the latter to electric motors on the driving wheel axles. By means of suitable resistances controlled by simple switches it is possible to provide the driver with an easy and effective means of control for starting, accelerating, and stopping. The larger Diesel locomotives generally employ this electrical transmission system.

Compactness is another advantage of the Diesel locomotive. Since there is no boiler in front, a much better field of view is obtained from the driver's cab than would be possible in a steam locomotive.

The relative shortness of the high-speed Diesel engine, as compared with the boiler and smoke-box of a steam locomotive, is another factor making for a better view ahead.

The Diesel engine is generally - although not invariably - placed vertically on the locomotive frame, and is encased in a sheet metal chamber, or “bonnet”, somewhat on the lines of a motor-car bonnet. This is provided with hinged or removable doors having a series of louvres, or slots for cooling purposes.

The water employed to cool the cylinder heads and barrels is in its turn cooled by means of a radiator, or radiators, placed in front so as to obtain the maximum cooling effect. A belt-driven four-bladed fan is usually arranged behind the radiator, as in motorcar practice. When the locomotive is working at low speeds or with a following wind, the cooling fan becomes a necessity - otherwise the water in the radiator would probably boil.

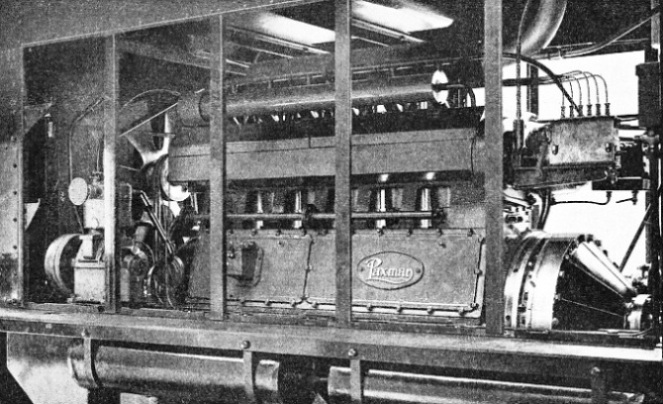

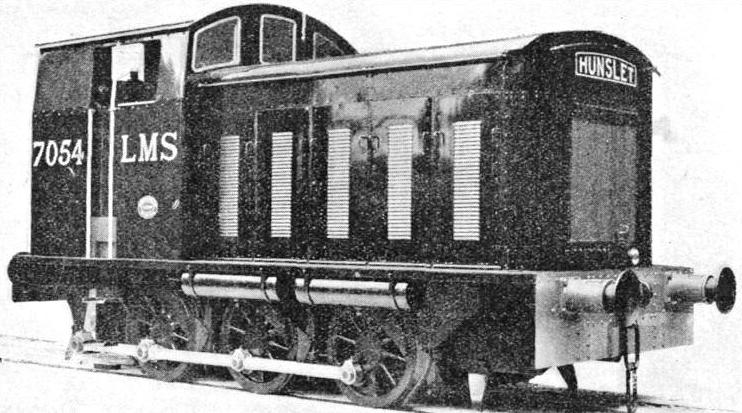

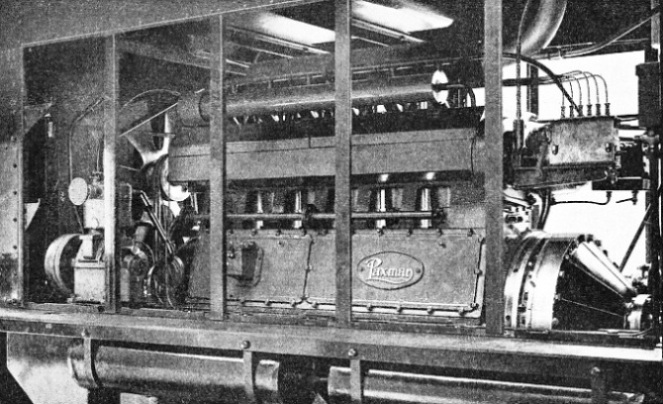

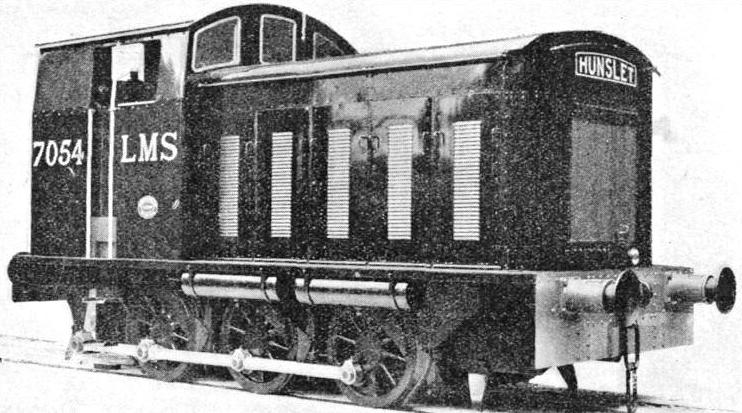

IN SERVICE ON THE LMS. The 200hp Davey Paxman Diesel engine of a Hunslet locomotive. The small compressor for supplying air to the brakes and be seen on the left side. Four engines of this type have been supplied to the LMS for shunting purposes.

The controls sometimes appear to be more complicated than those of the steam locomotive - and in some instances it must be admitted that they are. But in the larger locomotives employing hydraulic or electric transmission they are much simpler. There are, for example, no clutch to operate and no gears to change; neither is there a steam boiler to keep fired and fed with water. Instead, there is a compact engine that requires no attention while running and has its speed controlled by one simple lever.

There are, of course, instruments that require an occasional glance; these include the oil pressure gauge, engine revolution meter, and vacuum gauge, and voltmeter and ammeter for locomotives having electrical transmission.

The starting of the high-compression Diesel engines now presents no difficulty to the driver. Once the engine has started it will be found to pull at almost full power within a minute or two; it has a marked advantage over its petrol engine rival in this characteristic.

The smallest engines when cold are often started by hand with the help of a device for temporarily releasing the engine compression. In the larger engines electric glow plugs - that is, resistances placed in the combustion chamber and heated to redness by means of an electric current supplied from a battery - are generally used for starting from the cold condition. In one or two instances special cartridges are ignited and placed in a compartment connected with the combustion chamber.

A small petrol engine of about 3 to 4 hp is sometimes fitted for starting the larger Diesel engines, though compressed air, supplied from a steel cylinder, may be used instead.

Following Motor-Car Practice

When the electrical transmission system is employed engine starting is a very simple operation. The driver merely presses a push-button switch. This causes the generator to work as an electric motor, using current supplied from a battery, so that the engine crankshaft is made to revolve until the engine begins to “fire”.

A PART SECTIONAL VIEW of a Beardmore 300hp Diesel engine used in railway work. The form of William Beardmore, Ltd, supplied the engine for the 2,660hp Canadian National Diesel-electric trains.

A few representative Diesel locomotives will now be described. The Drewry narrow-gauge Diesel locomotive - one of the smallest - is built for a 2 ft gauge and is fitted with a four-cylinder high-speed Diesel engine developing about 38 hp at its normal speed of 1,000 rpm and over 50 hp at its maximum speed of 1,400 rpm. The engine mounting and transmission system resemble those of a commercial motor vehicle. Thus the drive from the engine is taken through a friction clutch to a three-speed gearbox, having the usual reversing gear. The final drive is taken off the layshaft and transmitted to the first driving axle. The second axle is coupled to the former by coupling-rods. The frame is made in box form of built-up plate construction; its weight is carried on the axle-boxes by four laminated springs.

The engine and its radiator are mounted at the front end of the locomotive, as in automobile practice. It is provided with an electric starting motor having a sliding “Bendix” pinion, the teeth of which engage with similar ones on the rim of the engine flywheel.

The various adjustable parts of the engine, as well as the fuel pumps, oil filters, water-circulating pump and starting motor, are all readily accessible, being mounted above the footplate. The fuel tank is mounted above the engine, and feeds the fuel injection pump by gravity. This pump, at the correct moment, supplies the small quantity of fuel required for combustion to the injector nozzles in the cylinder head. The Drewry locomotive is 11 ft 6-in long, 9 ft 2-in high and 5 ft wide. The wheel-base is 4 ft, and the four wheels are each 2 ft in diameter. This engine has a maximum speed of 15 mph and gives a starting tractive effort, or drawbar pull, of 3,360 lb.

A range of Diesel locomotives has been built by the Hunslet Engine Company of Leeds, including both small and large types. The former are built in the 20, 30, and 40 hp sizes and use two-cylinder high-speed Diesel engines operating at speeds up to about 1,000 rpm. The engine speed is, however, controlled by a governor, so that during idling periods the speed can be automatically reduced to 300 rpm; this is an advantage when the locomotive is standing still during its normal working operations.

The arrangement of the engine and radiator is the same as in the small locomotive described above. A two-speed gearbox with reverse gear is used for giving the usual forward speeds of 3 and 6 mph. By using special gearboxes higher speeds of 6 and 12 mph are made possible.

The small Hunslet engines all use the 0-4-0 wheel arrangement. They weigh 4, 5, and 6 tons each, and at 3 mph will haul on the level loads of 106, 160, and 212 tons, respectively. At the higher speed of 6 mph these loads are halved. The larger Hunslet locomotives include a 200 hp model, four of which have been supplied to the LMS Railway for shunting purposes.

One of these locomotives, which is of the 0-6-0 wheel arrangement, bears the LMS running number 7054. Embodying a number of new features, it is the largest of the series. It weighs about 30 tons, and develops a maximum of 200 hp, which makes it about twenty-five per cent more powerful than any of the others previously supplied.

The engine is a six-cylinder unit developing 180-200 hp, with a normal speed of 900 rpm. It is manufactured under special patents, the whole of the engine frame being fabricated.

Hauling 700 Tons

The governor control is operated in conjunction with the lubricating oil pressure, so that, should the latter fail in service, the governor will be non-operative, this preventing mechanical breakdown due to lubricating oil failure.

The camshafts, set on either side of the cylinder heads, are chain-driven from the fly-wheel end of the crankshaft. The drive is taken through a hydraulic coupling of the traction type, carried on the engine fly-wheel. Behind the coupling on the driving shaft is placed the rocking brake, which holds the shaft against the drag of the coupling while the gears are engaged, the rocking action being necessary to disengage the gears after the locomotive has been brought to rest. A clutch is placed between the hydraulic coupling and the gearbox, to facilitate gear changing.

Perhaps the most important of the auxiliaries is the equipment for starting. This is carried out automatically, the power being derived from a two-stroke petrol engine. The whole of the control is manipulated from the cab, the operation being carried out in about twenty seconds under the coldest conditions.

A compressor is arranged to supply air for the “Westinghouse” straight air brake, and to feed various auxiliary controls, such as the rocking brake and air whistle.

The cab is of a new design and gives an exceptionally good look-out, besides being pleasing in appearance; all the driving controls are duplicated on either side.

The weight of the locomotive is 30 tons, and the gearbox gives speeds of 4, 8, and 13 mph, the respective tractive efforts being 14,400 lb on lower gear, 7,200 lb on second gear, and 4,400 lb on top gear.

This locomotive is capable of hauling loads up to 700 tons. Other Hunslet locomotives supplied to the LMS Railway include a 150 hp model fitted with an eight-cylinder engine.

The LMS has also introduced into service a Diesel shunting locomotive built by Messrs. Harland and Wolff of Belfast. This six-wheeled locomotive, which carries the company's number 7057, has a total weight of approximately 27½ tons, all available for adhesion. The tractive effort at starting is 11,200 lb.

No. 7057 is designed for control by one man, and has the normal driver’s cab provided with duplicate controls for easy operation from either side of the cab, in which there are windows to provide a clear view of the track both backwards and forwards.

CAPABLE OF HAULING 700 TONS, this Hunslet Diesel shunting locomotive weighs 30 tons and has a Davey Paxman 200 hp Diesel engine. The gearbox gives speeds of 4, 8, and 13 mph. This locomotive operates on the LMS Railway.

The two-stroke four-cylinder engine is designed to develop 175 bhp at 1,100 rpm. It is fitted with an over-speed governor cutting out at 1,250 rpm. In normal service the revolutions are about 850 rpm, the higher speed being used for purposes of acceleration.

The engine is started by compressed air stored in reservoirs at a pressure of 375 lb per sq in. To facilitate starting from cold, a glow plug, heated electrically from the accumulators, is fitted in each cylinder.

The engine is of the airless injection type, and has a rotary scavenge blower, gear-driven from the crankshaft. An efficient uniflow system of scavenge enables the engine to develop a mean pressure equal to that of the four-stroke engine, with the added advantage of the even turning moment Of a two-stroke engine.

Each cylinder has a separate fuel pump supplying fuel under pressure to the automatically operated fuel valves in the cylinder heads.

The transmission is by means of a hydraulic coupling to a two-speed gearbox, and thence through a cardan shaft to the front axle of the locomotive. The reverse gear is engaged by means of dog clutches while the locomotive is at rest. The gearbox is the two-speed type in which the gears are constantly in mesh. All the gear-changing motions are performed by one lever duplicated on either side of the cab, so that the operation of the locomotive requires a minimum of skill and drivers easily become used to it. The final drive is by means of a high-efficiency worm gear. The radiators are cooled by a fan chain-driven from the engine crankshaft. The fuel tank has a capacity of 105 gallons and the water tank holds 55 gallons.

Messrs. Hawthorn, Leslie & Co Ltd, of Newcastle, have built a number of Diesel shunting locomotives. One of these was supplied to the Air Ministry for shunting and haulage work over a six-miles branch line of 4 ft 8½-in gauge track at Cranwell, Lincs.

The six-cylinder high-speed Diesel engine has cylinders of 6½-in bore and 9-in stroke. It has a speed range from 400 to 1,200 rpm and gives 225 hp at the latter speed. It employs the hydraulic transmission system. The 0-6-0 wheel arrangement is used. The locomotive weighs 27 tons.

The same firm, working in conjunction with the English Electric Company, Ltd, has produced an interesting Diesel shunting locomotive. The general particulars are as follows: gauge 4 ft 8-½ in; type 0-6-0 (six wheels coupled); wheel diameter, 4 ft 0½-in; wheelbase, 11 ft 6 in; total weight in running order, 47 tons; minimum radius of curvature, 290 ft.

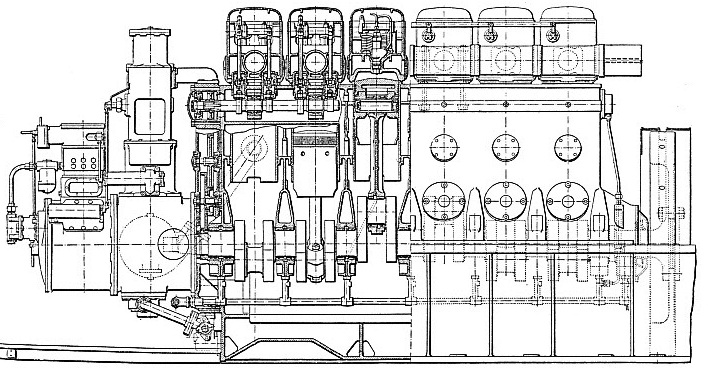

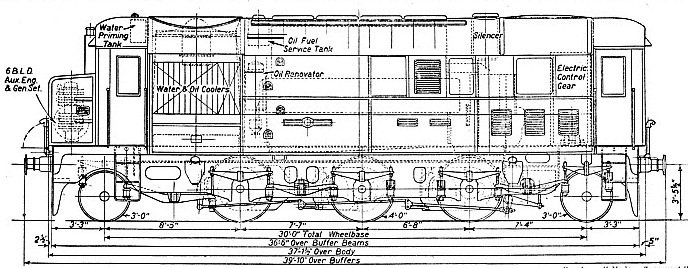

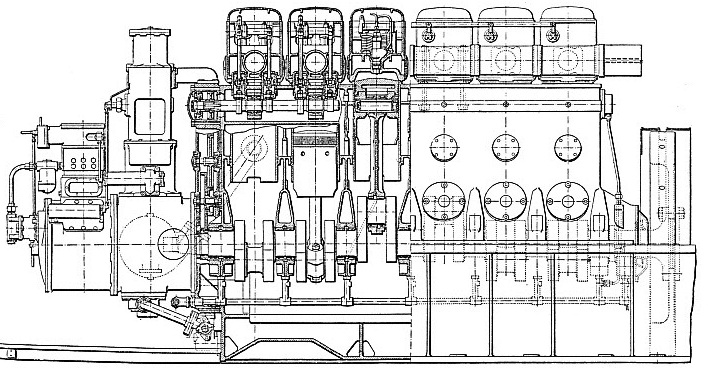

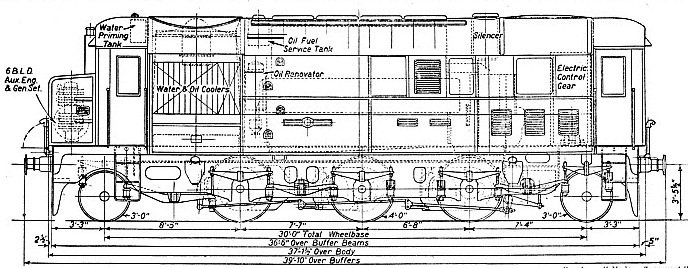

ELEVATION showing the general arrangement of an Armstrong Whitworth 880hp oil-electric locomotive which has been used experimentally for mixed traffic working on the LNER. This 2-6-2 locomotive has a maximum speed of 70 mph, and a tractive effort of 28,500 lb.

This locomotive has a 300 hp six-cylinder Diesel engine driving a 230 kw main generator and an 11 kw auxiliary generator. There are two driving or tractor motors. The greatest tractive effort, 30,000 lb, is exerted at the lowest speed of about 2 mph. At 10 mph the tractive effort is 10,000 lb, and, at 20 mph, about 4,000 lb. The maximum speed is about 35 mph. The flexibility of the electrical transmission is illustrated by the fact that the locomotive will haul on the level a 1,000 tons freight train at 10 mph or a local passenger train of 100 tons at about 35 mph.

One of its most striking features is its availability for continuous service. It can remain at work for practically twenty-four hours a day, for six and a half days a week, without shed attention or refuelling. Considerable operating economies are thus possible.

A similar locomotive has been in service for some time on the LMS, and has satisfactorily undertaken all types of shunting work; it has been tried in the shunting yards at Crewe, Rugby, Beeston, Toton, Camden, Salford, Healey Mills, Wakefield, and Carlisle.

The equipment is housed with a view to accessibility and ease of replacement. The superstructure is divided into three compartments: driving cab, control compartment, and engine compartment. In the cab there are two separate driving positions, one on either side of the cab, each having a driving control handle, reversing handle, and brake controls.

In the control compartment all control apparatus is mounted on a self-contained framework, and is easily accessible for inspection through swing doors in the driver’s cab. This framework can be removed complete through the detachable roof of the locomotive to facilitate overhaul and replacement.

The Diesel engine and generator set are mounted in the engine compartment on a three-point suspension. The arrangement ensures that no racking strains from the locomotive structure are transmitted to the engine crankcase or crankshaft; it also facilitates removal and replacement and obviates the necessity for re-alignment. The roof over the engine compartment is detachable, and this permits the power unit to be lifted out when necessary. Hinged removable doors on either side of the engine compartment give ready access to the power unit.

Electric Torque Controls

The two driving motors are mounted on the two outside axles and are supported by brackets from the locomotive under-frame. The brushgear and commutators can be inspected through doors in the locomotive floor. The complete motors can be removed cither by lifting the superstructure clear of the axles, or, if more convenient where no crane is handy, the motors can be dropped down into a pit, the supporting brackets being removable.

The cab is of the fully-enclosed type, and is fitted with an electric heater, which can be controlled by the driver. A cupboard is provided for the driver's clothes, and a small electric hotplate enables him to cook food.

In this locomotive is embodied the first application of electric torque control. The general principle of this system is that the Diesel engine speed is held to a pre-selected value by varying the electrical loading to suit the existing track load of the locomotive. This control is entirely automatic and is achieved by means of instantaneous regulation of the main generator field through a pulsating electric torque delay. Overloading of the Diesel engine is thus entirely avoided and the whole operation is made foolproof. The manipulation by the driver of a single lever controls the whole equipment automatically.

The Diesel engine is one of a series of medium speed engines developed and standardized for traction and industrial work. These engines are made with six, seven, or eight cylinders, and develop 300, 350, or 400 hp respectively at 600 rpm. Each cylinder has a bore of 10-in and stroke of 12-in.

A vertical water cooler is mounted at one end of the locomotive, a centrifugal pump being driven from the camshaft. In addition, the lubricating oil is circulated by means of an engine-driven pump through a separate section of the cooler. The cooler is used with an electrically driven fan which is thermostatically controlled, to maintain the lubricating oil and cooling water at the desired temperature.

The superstructure is of steel, housing completely the radiator, engine and generator, control framework, and all auxiliary apparatus. The roof is made detachable and in sections to facilitate removal of the power unit and auxiliaries.

Dual brake equipment is fitted, comprising straight and automatic airbrake and vacuum-brake; thus the locomotive is able to handle any type of stock on British railways. In Shunting work the straight air brake is used, but the automatic brake is available for local passenger service; the vacuum brake is available for the same service. A screw-down hand brake operating through the power-brake mechanism is also fitted.

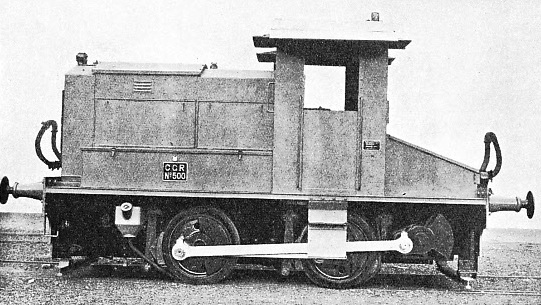

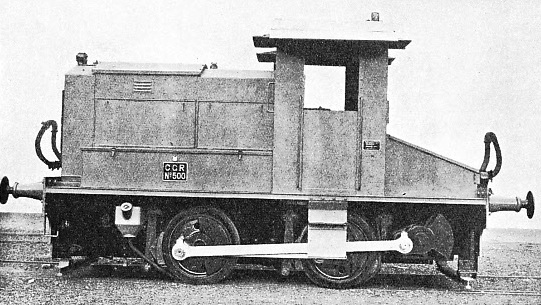

THE CEYLON GOVERNMENT RAILWAYS employ this 20-tons Diesel shunting locomotive. Engines of this type are now handling all the shunting in and out of the workshops.

The sanding gear is hand controlled from either side of the driver’s cab. Four sand boxes are provided, to deliver sand in front of the leading wheels and behind the trailing wheels. The locomotive began running in trial service on the LMS Railway in April, 1934. In eight months of continuous service the engine running time aggregated 4,000 hours. An opportunity was then taken to examine the conditions of the engine and electrical transmission, and the whole unit was found to be in excellent condition. In normal shunting conditions the consumption of fuel and lubricating oil averaged two to three gallons of fuel and one pint of lubricating oil per hour.

After the inspection, which lasted only a few days, the locomotive was returned to further service duties in the shunting yards of the LMS Railway.

Messrs. Armstrong Whitworth, Ltd, have produced, at their Scotswood Works, Newcastle-upon-Tyne, a wide range of highly satisfactory Diesel locomotives.

At one end of the range is a 15-tons light shunter incorporating an Armstrong-Saurer six-cylinder 110 mm. bore high-speed oil engine of the traction type, developing 110 bhp. A standard range was evolved from 15 tons to 30 tons, the larger sizes having the Armstrong-Saurer 150 bhp engine of 130 mm bore and 180 mm stroke. Several were sold to industrial users at home and overseas, and one to the North Sunderland Railway for mixed passenger and goods service and light shunting in yards or small junctions.

Another range of shunting locomotives made at the Scotswood works included a 40-tons type fitted with a 250 hp engine. For test purposes this underwent four months’ service of twenty-four hours a day for six days a week in goods and mineral yards of the LNER. Its performance was found equivalent to that of larger steam locomotives, and the running-cost saving was considerable.

After this, some six weeks’ trial running in yards of the Southern Railway was undertaken, and then a period of service in industrial yards. The outcome of the working of this locomotive was the supply to the LMS of a machine of a similar type.

A Versatile Locomotive

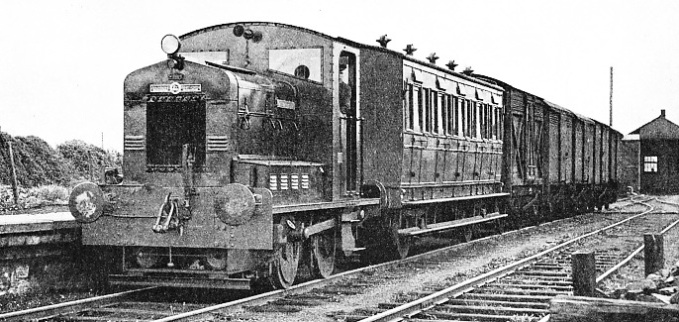

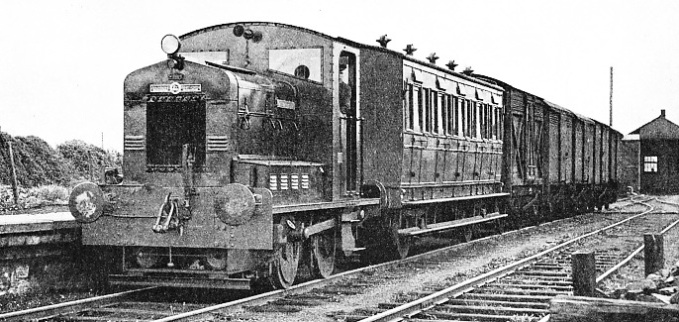

It was then decided to prepare a machine capable of passenger, goods, and general service operation, and the demonstration model was a 2-6-2 locomotive of 880 bhp, giving a maximum speed of 70 mph and a maximum tractive effort of 28,500 lb. After various demonstrations it was arranged that it should operate, by the courtesy of the LNER, on express goods service between Newcastle and York. After the first stage double-shift working was introduced and the route was extended to Berwick, including express parcels and meat trains. In these circumstances the daily mileage was 289, the engine pulling loads up to 600 tons. The fuel consumption was 17 lb (2 gallons) per 1,000 gross-ton miles, taking the average for eleven weeks, and the lubricating oil consumption was 0.025 gallon per 1,000 gross-ton miles. This locomotive was later placed in service on passenger train duties on the Newcastle-Carlisle route, thus demonstrating its versatility. In express passenger working with 250-ton trains its fuel consumption averaged about 20 lb per 1,000 gross ton miles.

The success of this class of Diesel locomotive has led to the decision to prepare two 5 ft 6 in gauge examples, for trial on the Ceylon Government Railways. In addition, an order has been secured from the North Western Railway of India for two 1,300 bhp 4-6-4 locomotives on the Karachi service, for goods or passenger working, either single- or double-headed, and operated by one crew. For the mail service these locomotives are designed to attain 60 mph with a 600-tons train, and when coupled will be considerably more powerful than the largest steam locomotives now at work in India.

The firm of William Beardmore, Ltd, has made a number of Diesel engines for passenger and shunting purposes. It supplied the engines for the 2,660 hp Canadian National Diesel electric trains.

One interesting shunting locomotive is a double-bogie Diesel electric 400 hp type, known as the Westinghouse-Beardmore, supplied for use on the Canadian National Railway. In November, 1929, a Beardmore Diesel locomotive ran over 10,000 miles in the Argentine, hauling loads of 112-290 tons at an average speed of 35 mph; fuel consumption was 20 gallons per hour.

A LIGHT SHUNTING LOCOMOTIVE built by Armstrong Whitworth, and weighing 15 tons. It is equipped with an Armstrong-Saurer six-cylinder engine which develops 110 bhp. The locomotive is seen at Seahouses, Northumberland, on the North Sunderland Railway.

You can read more on “British Diesel Rail Coaches”, “Coaches for Road or Rail” and “Diesel Locomotives” on this website.