Fuelling and Combustion

DESIGN AND INVENTION - 20

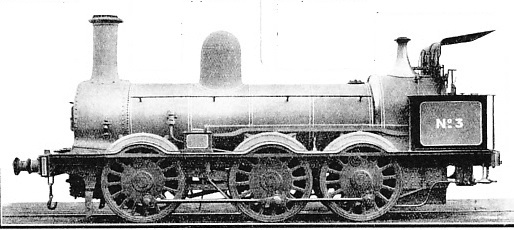

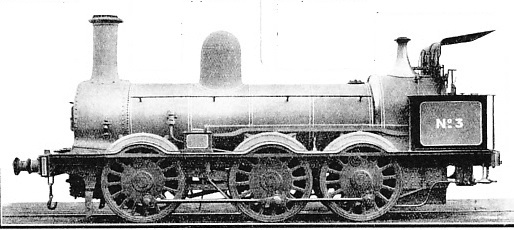

AN OLD LOCOMOTIVE constructed on the “long boiler" plan of Robert Stephenson. This involved the placing of all the axles under the boiler barrel and, while having certain advantages, prevented the use of a fire-box of any great size.

THERE are over 20,000 steam locomotives in railway service in this country, and in the course of a year they run some 531,000,000 miles. Taking the consumption of an express engine as two tons of coal for each 100 miles covered, the total amount of fuel used reaches very large figures. A small saving on each mile covered would mean a very large aggregate saving, with a corresponding reduction of expenses, so that the better use of fuel by enginemen is a subject in which railway companies are keenly interested. In a recent special publication encouraging the economical use of coal, the Great Southern Railways of Ireland point out that roughly half the cost of the Locomotive Running Department is accounted for by the purchase of coal. Since the earliest days economy in fuel has been sought after, and many and various are the devices that have been conceived with this end in view. In this article we propose to deal briefly with some of the developments in this direction that have affected the locomotive fire-box, and its fuelling.

British coal is of excellent quality, and no railway in this country is really situated far from a source of suitable supplies. Abroad, however, different conditions obtain, with the result that specially arranged fire-boxes are in use, suitable for inferior qualities of coal. Oil is also used as a locomotive fuel where it is obtainable. Wood is employed to some extent if readily available where coal and oil are scarce, and therefore dear.

In the early days of locomotives coke was generally used as a fuel, for the crude draught and fire-box arrangements did not allow of the combustion of coal without the emission of a considerable amount of smoke. The use of coke was even laid down by Statute in several cases, no doubt as a result of the widespread belief that the fumes from the “locomotive engines” would pollute the atmosphere to such an extent that wholesale mortality would result among livestock, not to mention human beings! The following restrictions with regard to fuel, which were laid down when the Warrington and Newton Railway was authorised, will illustrate this point.

“Every locomotive steam engine used within the parishes of Burtonwood and Winwick shall be constructed on best principles for enabling it to consume its own smoke and preventing noise in the machinery or motion thereof, and no coal, but only coke or such other fuel as shall be approved by Lord Lilford and the Rector of Winwick, shall be used or consumed on such locomotive on any pretence whatever.”

Gradually locomotive engineers endeavoured to abandon the use of coke, for it was expensive and inferior to coal. Three old-time experimenters who did much towards the development of coal-burning fireboxes were Beattie, McConnell and Cudworth, heads of locomotive matters on the LSWR, LNWR, and SER, respectively. Each of them produced “patent fire-boxes” that were somewhat extensively applied on their own lines, but these special forms were superseded, and indeed rendered unnecessary, by subsequent developments. Actually the Beattie and Cudworth systems were the subject of comparative trials, engines of each company taking a turn for a period of two months in working the chief expresses of the other in company with the “home guard”. Both sides appear to have been satisfied with the performances of their own engines, and both engineers continued to follow up their own ideas. The comparative value of the trials in a scientific sense was therefore evidently very small.

Of the forms of fire-box evolved by the three engineers in question, the McConnell type involved the use of a combustion chamber extended into the boiler barrel. Both the Beattie and the Cudworth types were more or less complicated, and the Beattie fire-box at first was used in conjunction with a combustion chamber partly filled with perforated firebricks. Eventually this arrangement was given up, but the special fire-box remained. It is curious in that it consisted of two chambers, one behind the other, separated by a water space or “bridge”, and each with its own firehole. The coal was mostly fired into the rear chamber, and the smoke and unburnt gasses passed from this into the front chamber, where the fire was maintained in an incandescent state, and so combustion was completed.

The Cudworth fire-box also was divided, but in this case the division was longitudinal. Two fireholes were again necessary, and the usual plan was to fire these alternately. The numerous joints necessitated by both of these special constructions must have given a great deal of trouble in repair and maintenance generally.

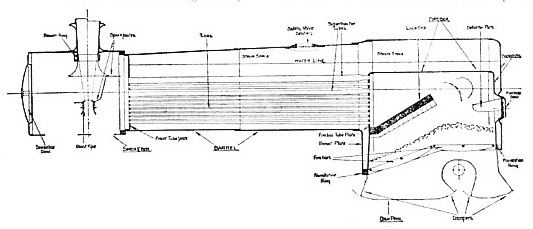

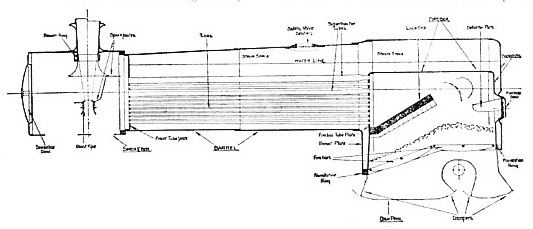

SECTIONAL DIAGRAM of a GWR locomotive boiler showing the smoke-box, boiler barrel and fire-box components, including the brick and deflector plate.

The illustration above shows the various components of the fire-box and boiler generally of a modern locomotive. It will be observed how the brick arch gives the fire-box two zones, or in effect two chambers of action. Below the brick arch the fuel is burned with air admitted from below through the fire doors and dampers; above the arch the gases and smoke are consumed with the air drawn through the firehole. The function of the deflector plate is to prevent the cold air that enters through the firehole from bearing straight on to the tube-plate. It will be realised, therefore, that the effects aimed at by the early experimenters are obtained with far more simple equipment and with less initial expense and subsequent maintenance. The introduction of a brick arch took place on the Midland Railway in 1858, and did away with the need for the special forms of coal-burning fire-boxes, although these persisted for some time afterwards on their own systems.

In this country it is the usual practice to use a fairly long, but narrow and deep, fire-box for burning the bituminous coals of good quality that are usually considered essential for locomotive purposes here. Exceptions to this are the “Pacific” and large “Atlantic” locomotives of Doncaster design running on the LNER, the similar “Atlantics” of the SR, and of course the LMSR 4-6-2 locomotives. The small trailing wheels of all these engines facilitate the adoption of the wide fire-box spread across the frames. It is noteworthy, however, that all the other “Atlantics” on British railways have narrow fire-boxes, in spite of the opportunity provided by the wheel arrangement for the incorporation of a wide one. The former “Atlantics" of the GWR also followed this practice, but as these were an adaptation of the original Swindon 4-6-0 design, and there was the possibility of their ultimate conversion to the latter type, this no doubt accounted for the use of the standard boiler and fire-box. The steaming qualities of the Doncaster “Atlantics” and “Pacifics” have always been remarkable, and there is little doubt that the large fire-boxes have much to do with this. They are able to burn efficiently quite small and even dusty coal. A wide fire-box is used also on the LNER 2-8 2 freight engines, and on the latest passenger engines of the same wheel arrangement, such as the famous “Cock o’ The North”.

With the increase in the size and power of locomotives made necessary by higher speeds and heavier loads, the work of the fireman has not diminished. Abroad, particularly in America, the vast fire-boxes in use demand more than man power for their satisfactory fuelling, with the result that numerous designs of mechanical stokers have been produced. These are not robots made to handle the shovel at abnormal firing rates, but consist primarily of a feed screw situated in an open-topped trough at the bottom of the coal space. As the screw is revolved the coal is fed forward below the cab floor, through a feed tube, up and into the fire-box. Special distributors enable the grate to be covered as necessary.

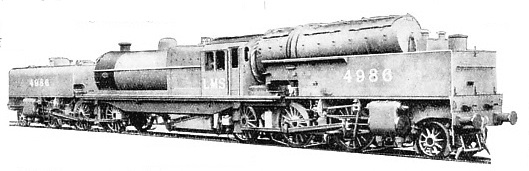

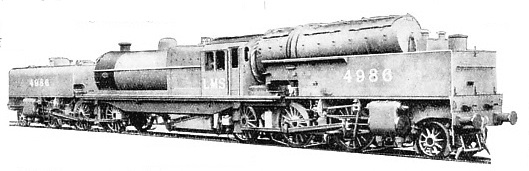

Such fittings are not yet apparently considered necessary on British railways, although as long ago as 1904 the GWR were experimenting with a mechanical stoker. However, on the “Garratt” type of locomotive used for specially heavy coal and mineral services on the LMSR, the opportunity has been taken of relieving the fireman of any of the coal-trimming frequently involved on a continuous steaming trip of any great length. This is effected by the use of a patent self-trimming coal bunker devised by Beyer, Peacock and Co. Ltd, whose name is specially associated with “Garratt” type engines. This mechanical coal trimmer takes the shape of a large cylinder mounted where a rectangular coal bunker would normally be. It is made to taper slightly outward from back to front, and its axis is inclined so that the top of the bunker is horizontal. The bottom therefore slopes downward to the cab. It is supported by suitable bearings; and can be revolved through gearing by means of two small stationary engines controlled from the cab. The bunker has doors on top for coaling purposes, but these are ordinarily kept shut. Thus as the bunker is revolved the coal is fed down to the shovel plate, whence the fireman transfers it to the fire-box.

This bunker can be revolved in less than half a minute, if required, and its use in between spells of firing avoids additional labour on the part of the fireman in getting coal forward. The loss of coal and the overloading caused by piling up the fuel in an ordinary tender is made impossible. In addition the coal is completely protected from the weather, which is a matter of more importance than is generally realised.

The burning of pulverised fuel in this country has been confined to experiments only, first on the former GCR in 1920, and more recently on the Southern Railway. Experiments were also made on the GCR at the same time with what was termed “colloidal” fuel, a mixture of pulverised coal and oil. In America many locomotives are fitted for burning pulverised coal; and in Germany successful experiments have been made with the native brown coal, or “lignite”, in pulverised form.

The use of oil fuel is common in regions or countries where supplies are easily available, but in this country in recent times it has been applied only as an emergency measure, when coal supplies have been interrupted owing to strikes. It is interesting, however, that about 30 years ago the former GER had in operation a very successful system of oil burning devised by their then Locomotive Superintendent, Mr J. Holden.

Within its limits the scheme was satisfactory and economical. As a result of the expansion of the system, however, it became no longer an economic proposition, owing to the rise in the price of oil. Among the GER engines fitted with the Holden apparatus were No. 760, specially named “Petrolea”, and many 4-4-0 locomotives of the “Claud Hamilton” class.

ONE OF THE LMS “Beyer-Garratt” locomotives fitted with the patent Self Trimming Bunker evolved by Beyer, Peacock and Co. Ltd.

You can read more on “Firing the Locomotive Mechanically”, “How a Locomotive is Built” and “The Locomotive Booster” on this website.